Wire arranging and gluing device for membrane wire

A gluing device and membrane filament technology, which is applied in membrane technology, semi-permeable membrane separation, chemical instruments and methods, etc., can solve the problems of easily damaged membrane filament surface, slow glue filling speed, heavy workload, etc., to reduce the resistance Decrease in pollution capacity, improve aeration efficiency, and increase packing density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

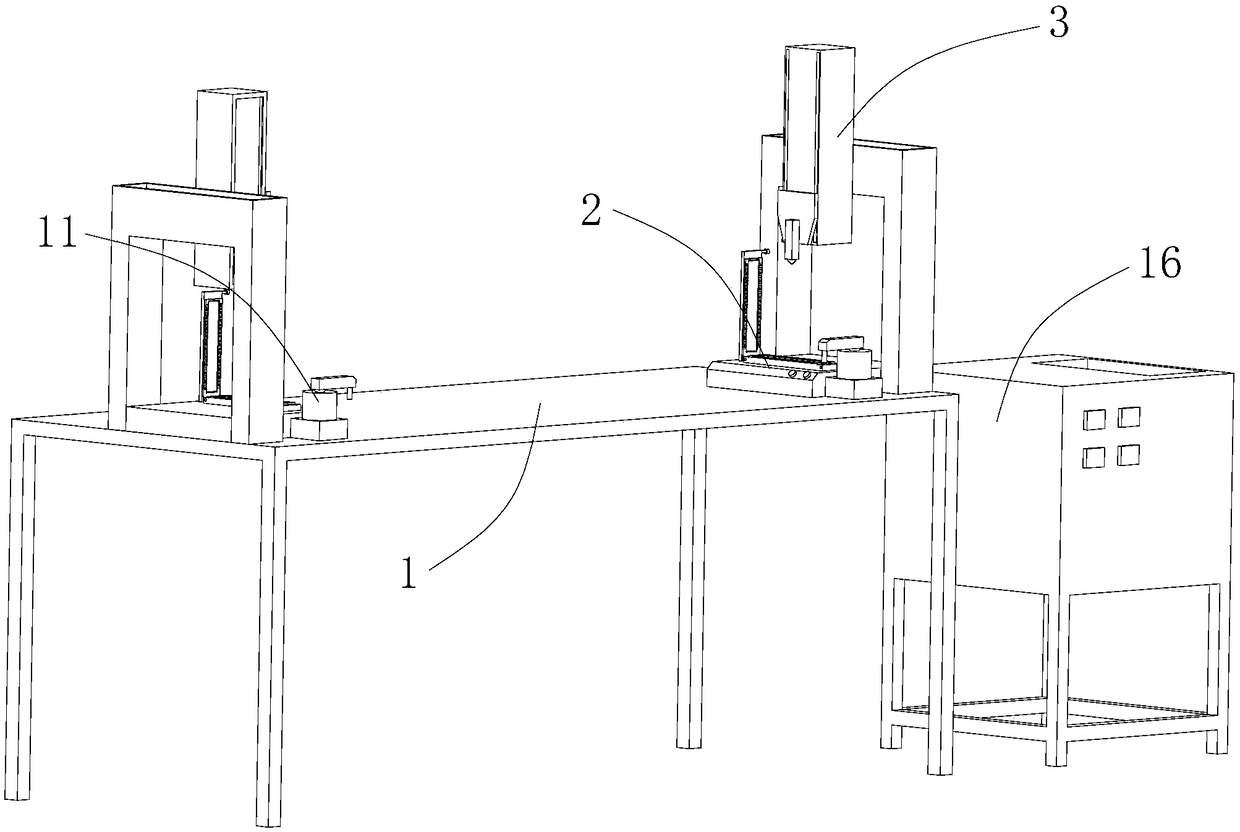

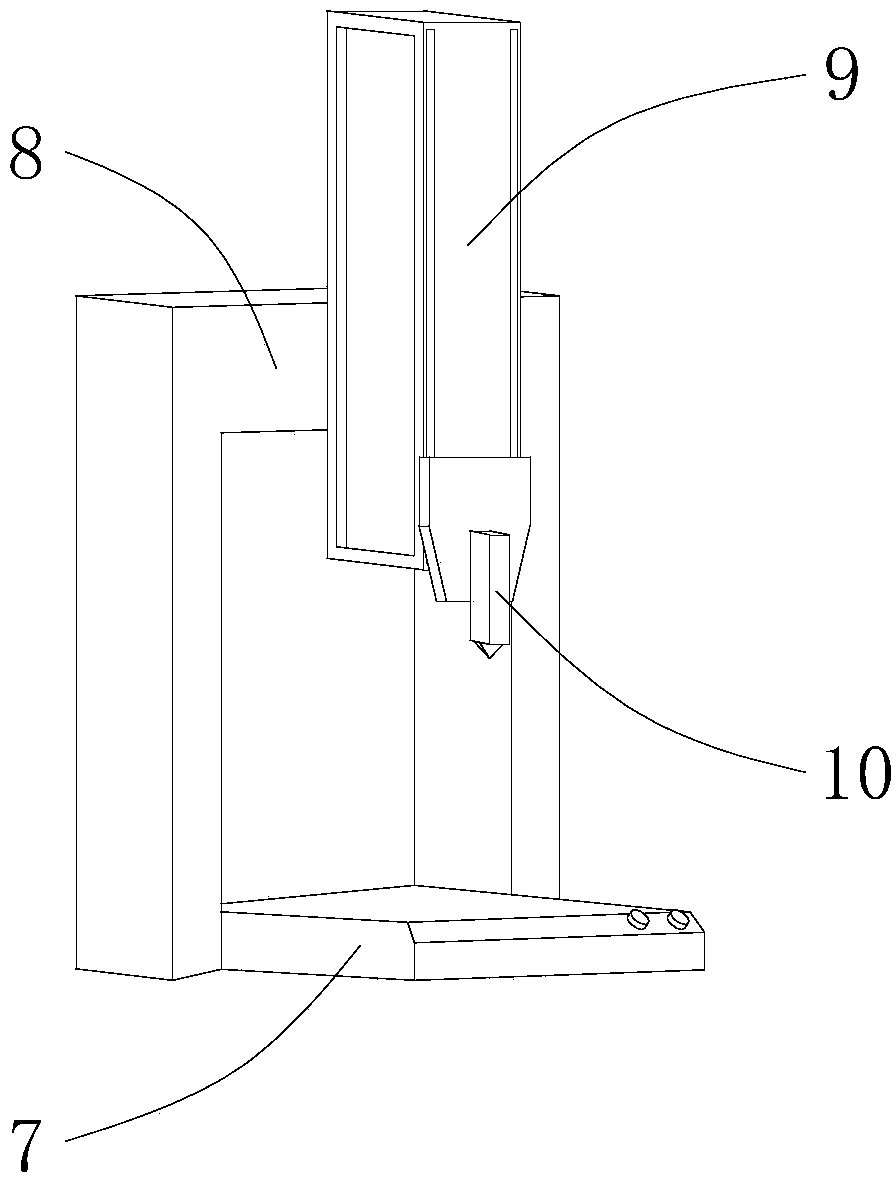

[0027] see Figure 1-4 As shown, the above-mentioned wire arranging and gluing device for membrane filaments includes a workbench 1, a wire arranging mechanism 2 arranged on the workbench 1, a gluing mechanism 3, a pressing mechanism 11, and a The gluing mechanism 3 provides a hot-melt glue machine 16 for hot-melt glue.

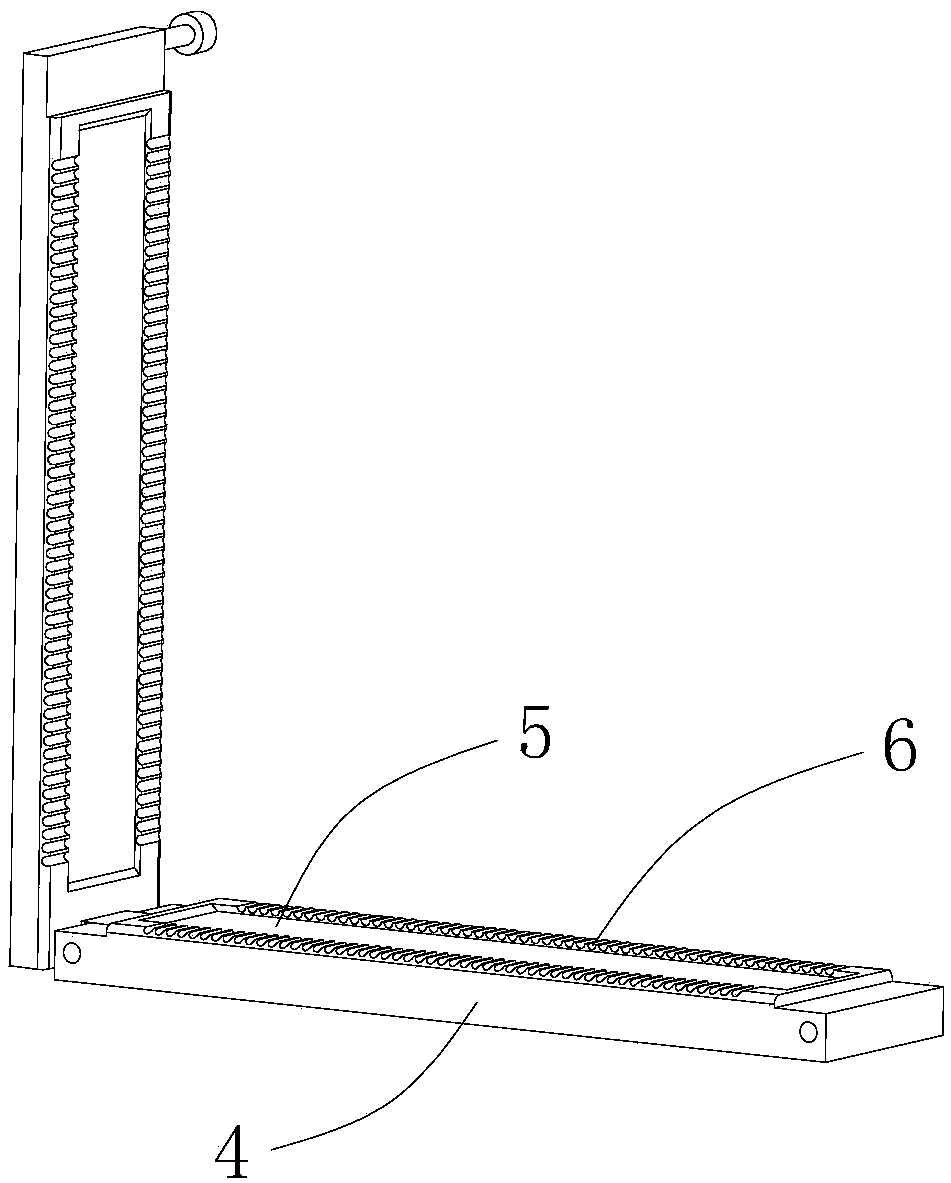

[0028] The above-mentioned wire arrangement mechanism 2 includes two wire distribution plates that can be used for pressing each other. Wherein, the thread distributing board includes a bottom plate 4, a glue injection groove 5 set on the bottom plate 4, and slots arranged on the bottom plate 4 at regular intervals along the length extension direction of the glue injection groove 5 for one-to-one corresponding insertion of film filaments. The wire row groove 6, the wire row groove 6 is located on both sides of the glue inje...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com