Rotational flow suction type dust haze charged dust removal device

A dust removal device, electrostatic spray dust removal technology, applied in electrostatic separation, steam flow control, electrostatic effect separation, etc., can solve the problems of high dust removal cost, reduced dust removal efficiency, large water consumption, etc., to avoid secondary dust phenomenon, improve The effect of dust removal efficiency and high water utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

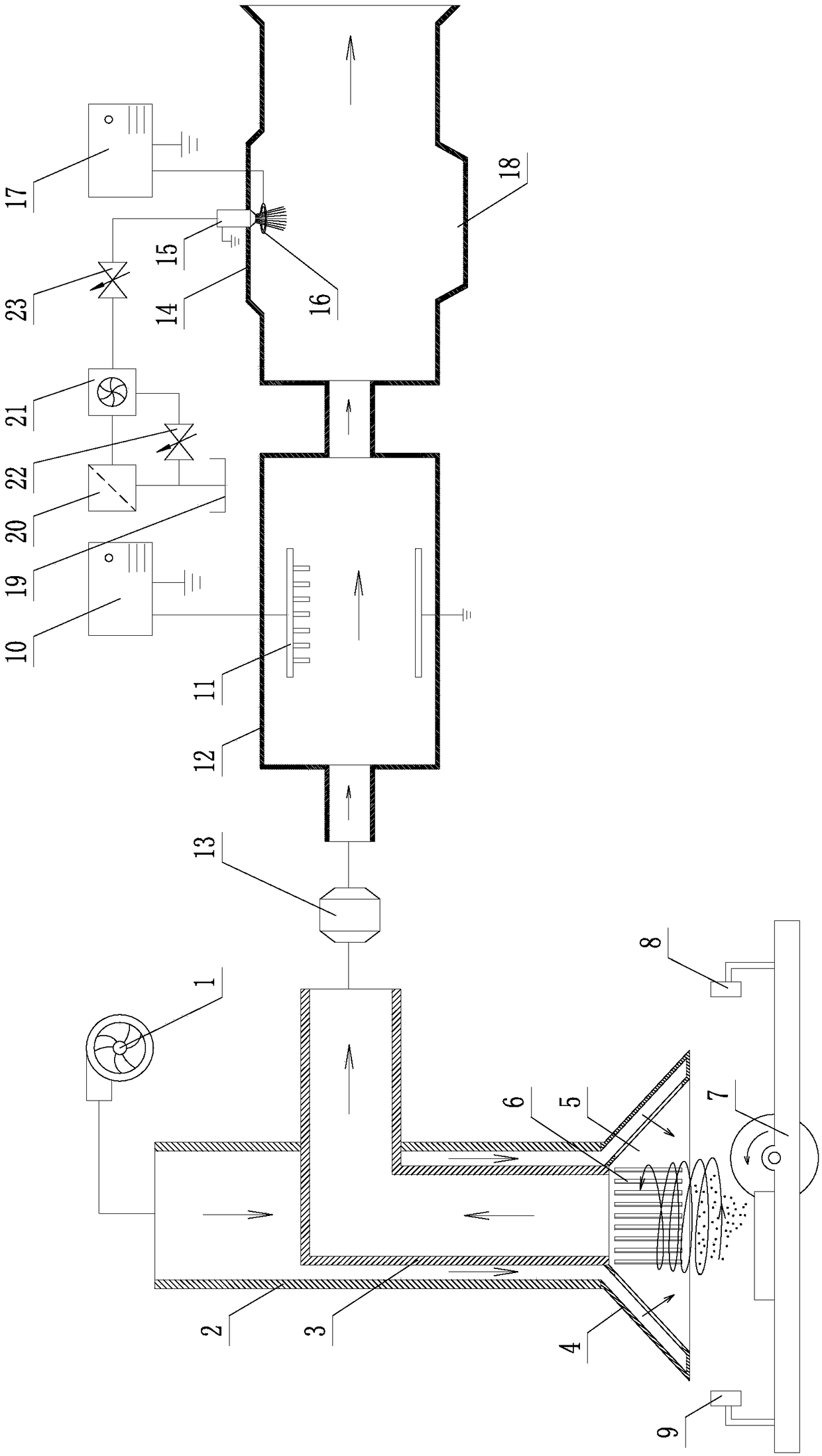

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

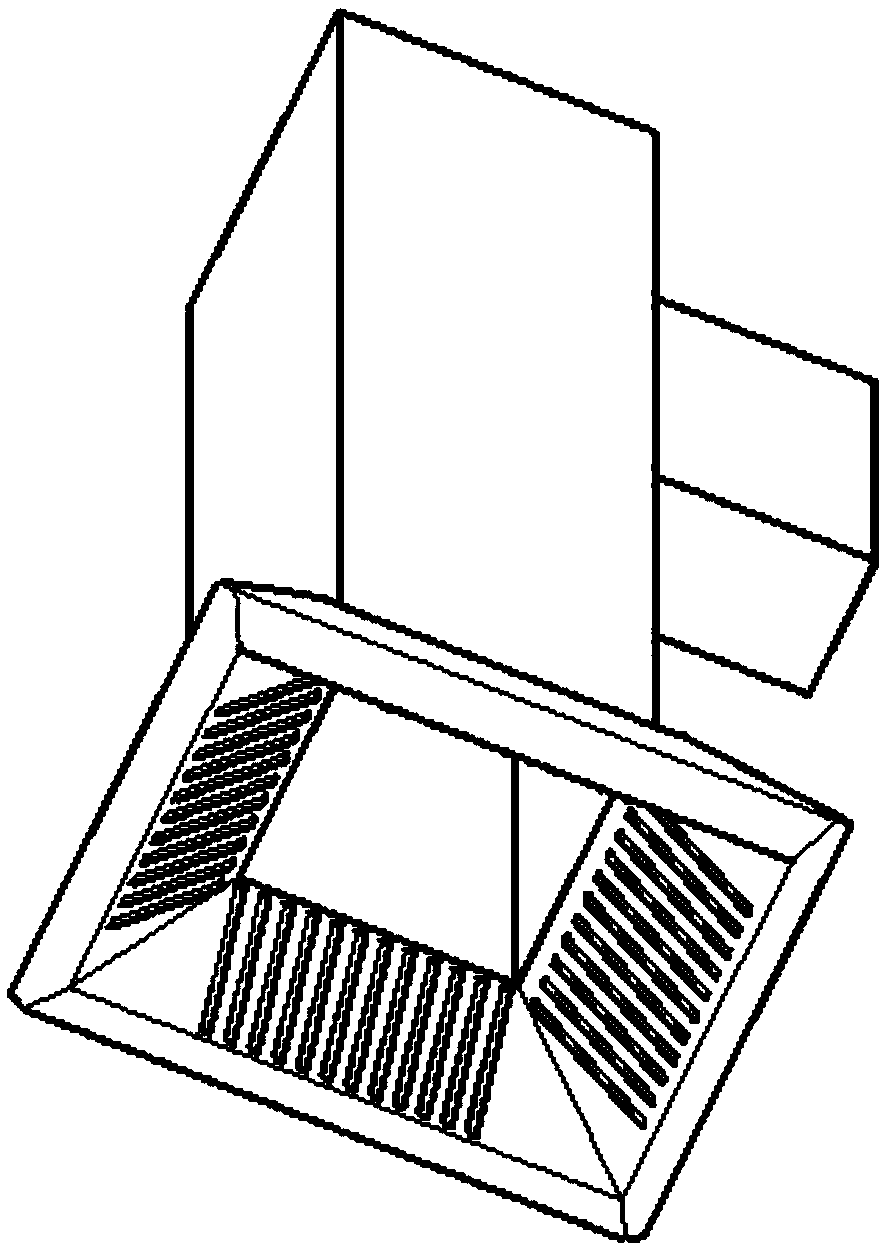

[0018] Such as figure 1 , 2 As shown, a swirl suction dust mist charging dedusting device includes a dust capture component, a dust corona charging component and an electrostatic spray dedusting component; the dust capture component is used to generate a rotary suction airflow, The airflow captures the dust particles in the working area; the dust corona charging component is used to charge the uncharged dust particles; the electrostatic spray dust removal component dedusts and purifies the airflow containing the charged dust particles.

[0019] The dust capture assembly includes a blower 1, an air supply duct 2, an exhaust duct 3, an air collection outer cover 4 and an air collection inner cover 5; The outer cover 4 is installed on the air outlet of the air supply duct 2, and the air inlet of the air supply duct 2 is connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com