Cyclone milling cutter with self-cooling lubrication structure

A technology of cooling lubrication and lubricating structure, which is applied in the direction of milling cutters, manufacturing tools, milling machine equipment, etc. It can solve the problems of high-precision external thread accuracy, the inability to cool the lubricating fluid, and the large amount of lubricating fluid used to improve the service life. , Good cooling and lubrication effect, uniform cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

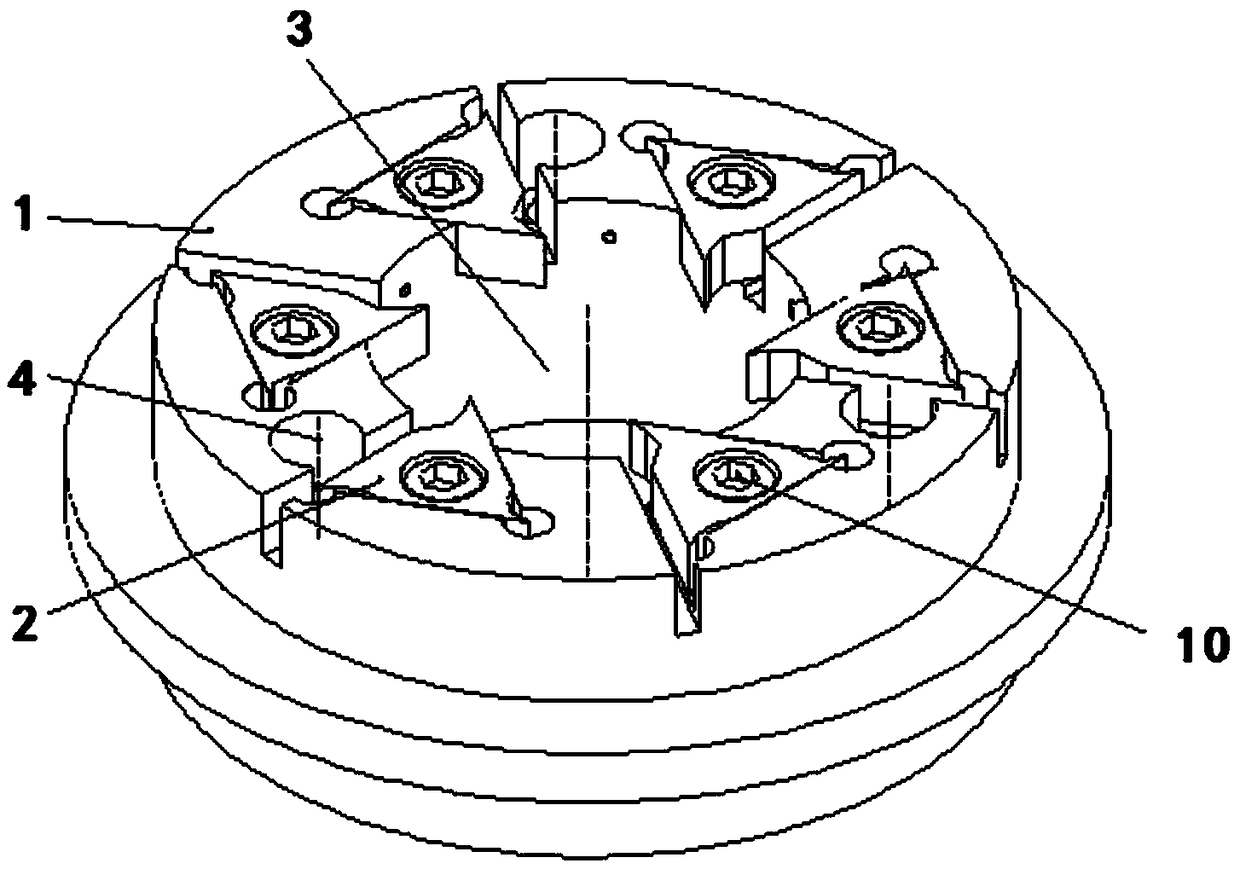

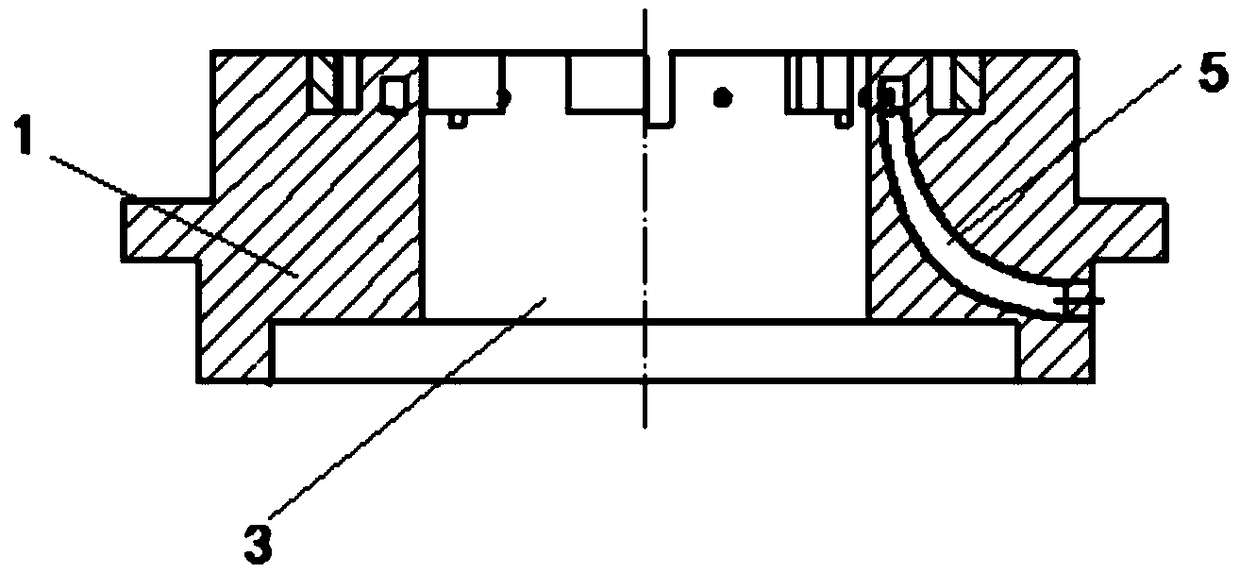

[0036] Such as figure 1 and figure 2 As shown, a whirlwind milling cutter with a self-cooling and lubricating structure includes a rotating base 1 and a plurality of thread milling inserts 2; the rotating base 1 is provided with a large through hole 3 along the central axis; the rotating base 1 is provided with A plurality of bases are connected with screw holes 4; one end surface of the rotating base 1 is installed with a plurality of thread milling inserts 2 along the circumferential direction; a plurality of cooling and lubricating fluid channels 5 having the same number as the thread milling inserts 2 are arranged in the rotating base 1 ; The inlet of the cooling lubricating fluid channel 5 is located on the outer surface of the rotating base 1, and away from the thread milling blade 2; The outlet of a cooling lubricating fluid channel 5 is facing the tip of a thread milling blade 2; the rotating base 1 and the cooling lubricating fluid channel 5 are all processed and fo...

Embodiment 2

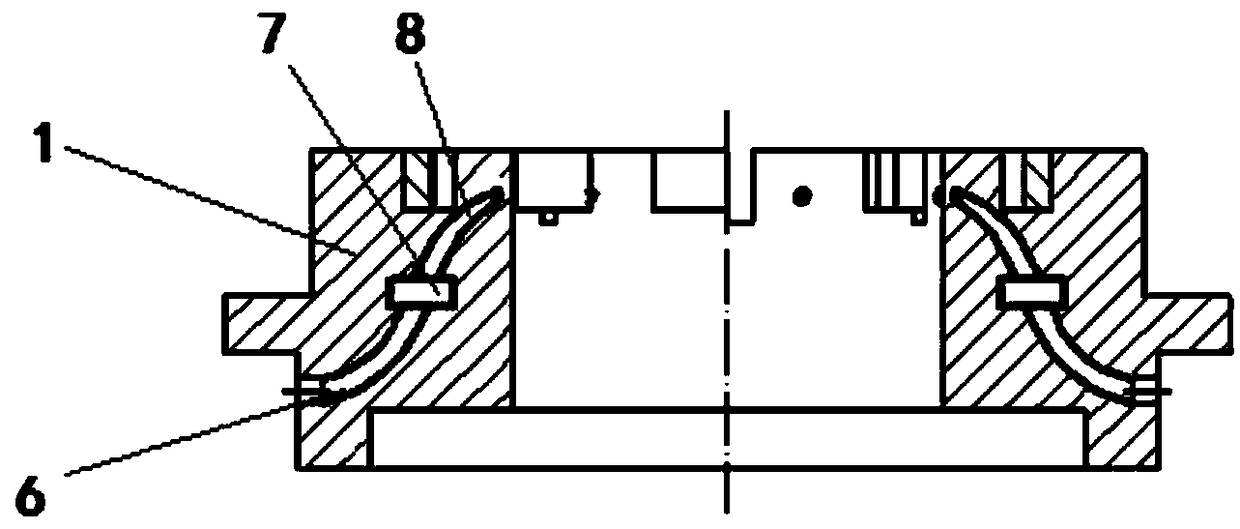

[0039] Such as image 3 As shown, on the basis of Embodiment 1, the present invention also provides another design: a whirlwind milling cutter with a self-cooling and lubricating structure, including a rotating base 1 and a plurality of thread milling inserts 2; the rotating base 1 A large through hole 3 is arranged along the central axis; a plurality of substrate connection screw holes 4 are arranged on the rotating base along the circumferential direction; a plurality of thread milling inserts 2 are installed on one end surface of the rotating base along the circumferential direction; at least one cooling and lubricating main flow is also included Road 6 ( image 3 The middle cooling and lubricating main channel 6 has the same number as the cooling and lubricating secondary channels 8), the middle annular cooling and lubricating fluid channel 7 and multiple cooling and lubricating secondary channels 8;

[0040] The cooling and lubricating main channel 6 is set away from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com