Hard alloy round rod polishing device

A technology of cemented carbide and round rods, which is applied in the direction of grinding machines, grinding workpiece supports, metal processing equipment, etc., can solve the problems of inability to achieve fast and high quality, reduce production efficiency, and low grinding efficiency, and achieve stable rotation and strengthened Grinding effect, effect of increasing the grinding area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

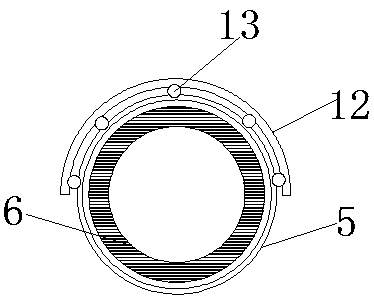

[0017] see Figure 1~Figure 2 , figure 1 It is a structural schematic diagram of a cemented carbide round rod grinding device provided by an embodiment of the present invention; figure 2 It is a structural schematic diagram of the grinding sleeve provided by the embodiment of the present invention.

[0018] The present invention provides a cemented carbide round rod grinding device, which comprises: a grinding platform 1 and a grinding workpiece arranged above the grinding platform 1; wherein, one side of the grinding platform 1 A rotating motor 2 is provided, and a turntable 3 is slidably arranged on the other side; the rotating motor 2 and the turntable 3 are respectively provided with tapered pressing members 4 for pressing against the centers of the two ends of the alloy rod 17;

[0019] The grinding workpiece includes a grinding sleeve 5 set on the alloy round rod 17, a grinding brush 6 is arranged on the inner wall of the grinding sleeve 5, and a first belt 16 wheel s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com