Self-protection shaft locking protection device for bearing grinder grinding shaft

A bearing grinding machine and protection device technology, applied in the direction of grinding drive device, grinding/polishing safety device, grinding machine, etc., can solve the problems of oil viscosity drop, wrench injury to staff, grinding wheel spindle fracture and damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

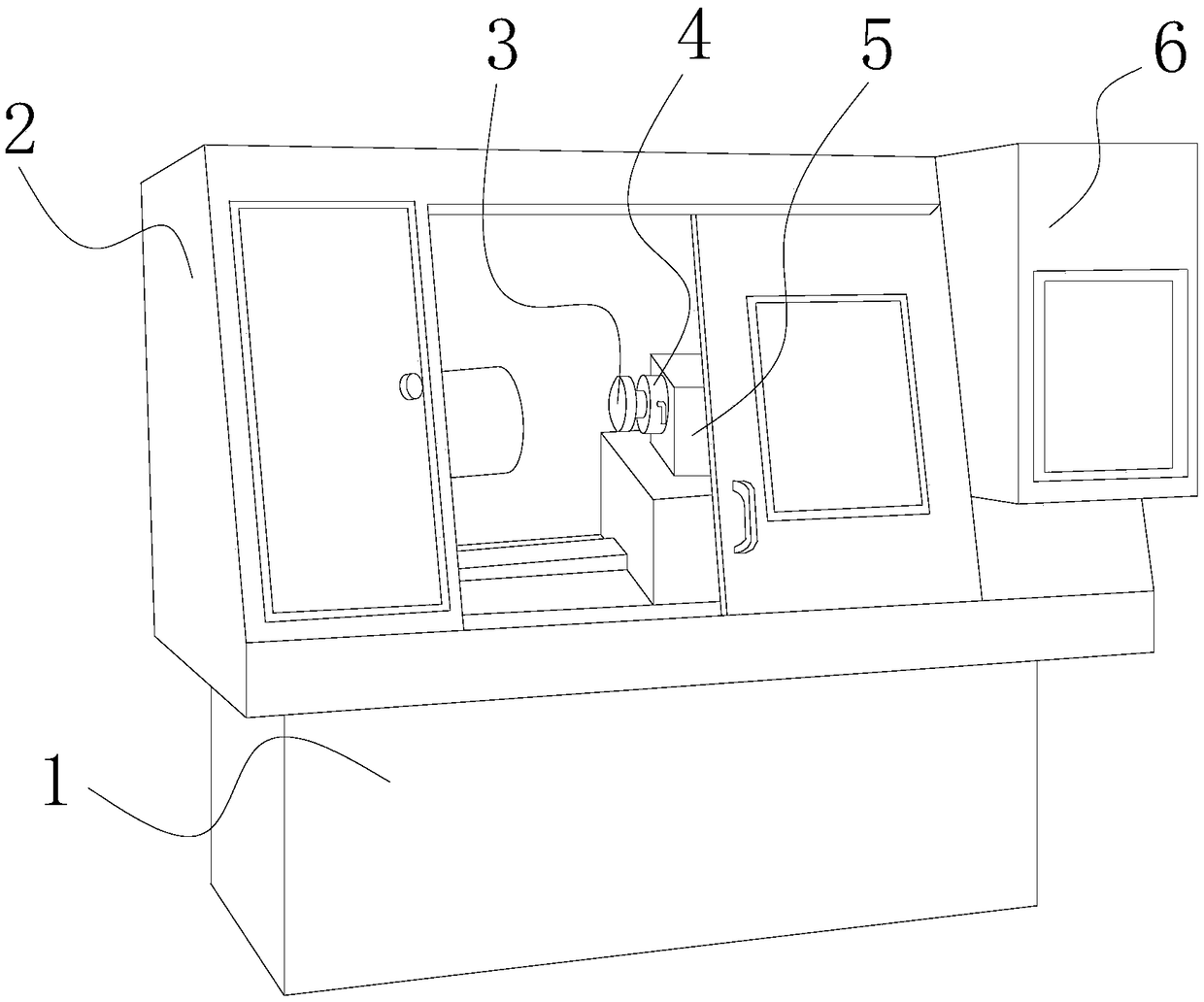

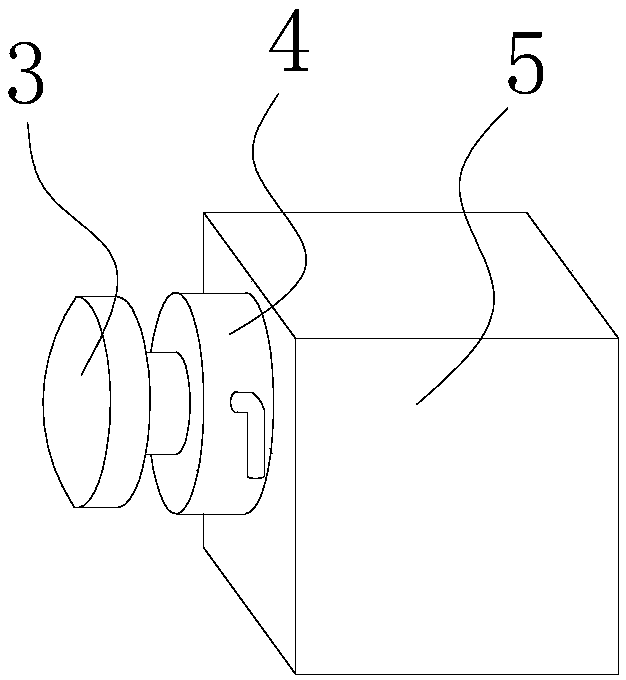

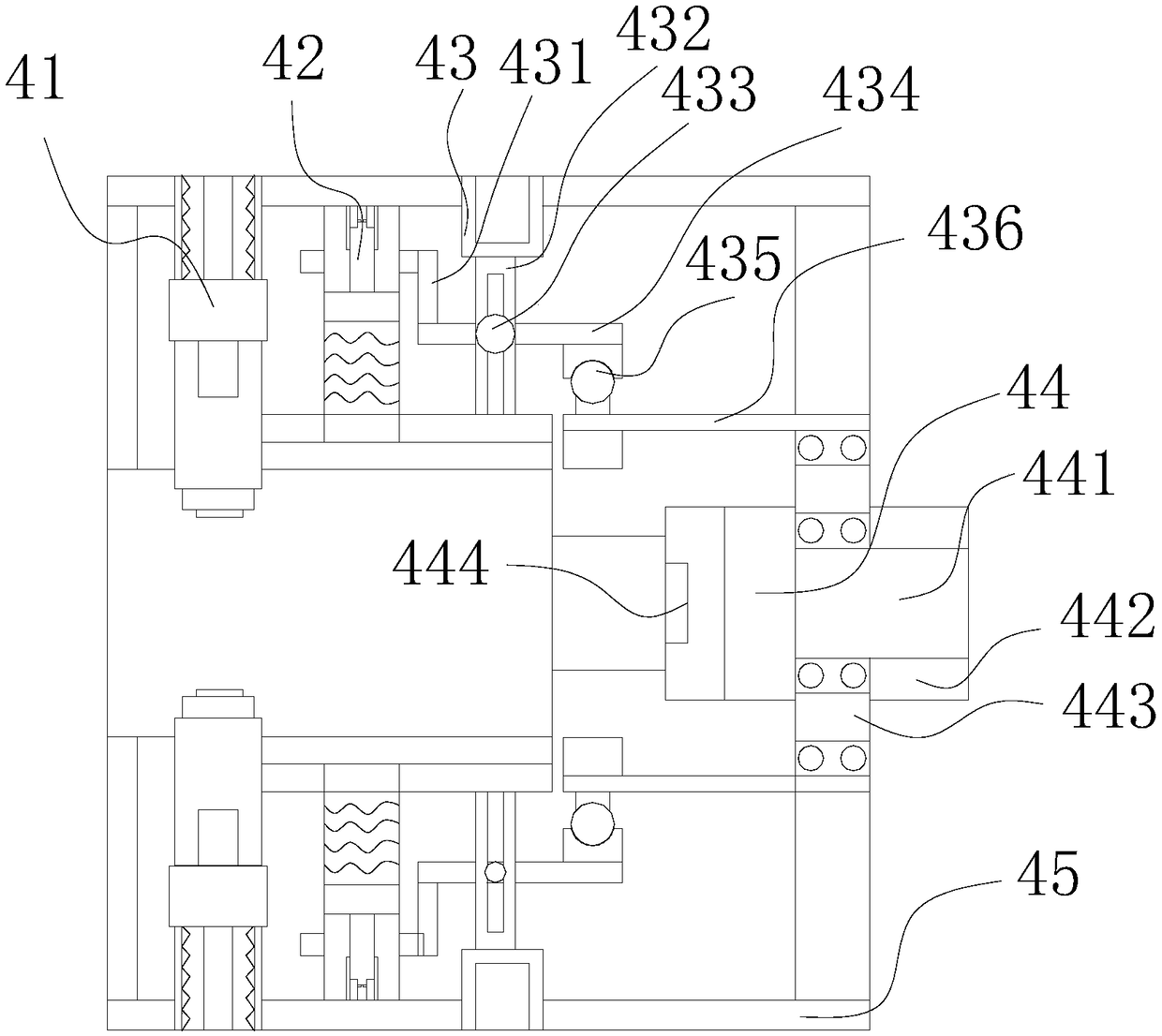

[0030] Such as Figure 1-Figure 9 As shown, the present invention provides a self-protection lock shaft protection device for a bearing grinder sand shaft, the structure of which includes a base 1, an operating cabinet 2, a grinding wheel 3, a fly shaft protection device 4, a transmission box 5, and a control box 6. The base 1 is horizontally installed on the lower surface of the operating cabinet 2, the grinding wheel 3 is connected to the fly shaft protection device 4 through the grinding wheel shaft, and the axes where the two are located are located on the same horizontal line, and the fly shaft protection device 4 It is horizontally embedded and installed inside the transmission box 5 and is mechanically transmitted through the shaft. The control box 6 is horizontally installed on the front surface of the operation cabinet 2. The knock-up shaft protection device 4 includes an anti-knock-up mechanism 41, a linkage transmission mechanism 42, a transmission mechanism 43, an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com