Transfer printing machine

A technology of transfer printing machine and reducer, which is applied in the direction of rotary printing machine, printing machine, transfer printing, etc. It can solve the problems of difficult control of the speed of the track pulley, long warm-up time when starting up, affecting transfer efficiency, etc., and achieves saving transfer. Reduce printing time, reduce labor burden, and improve transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

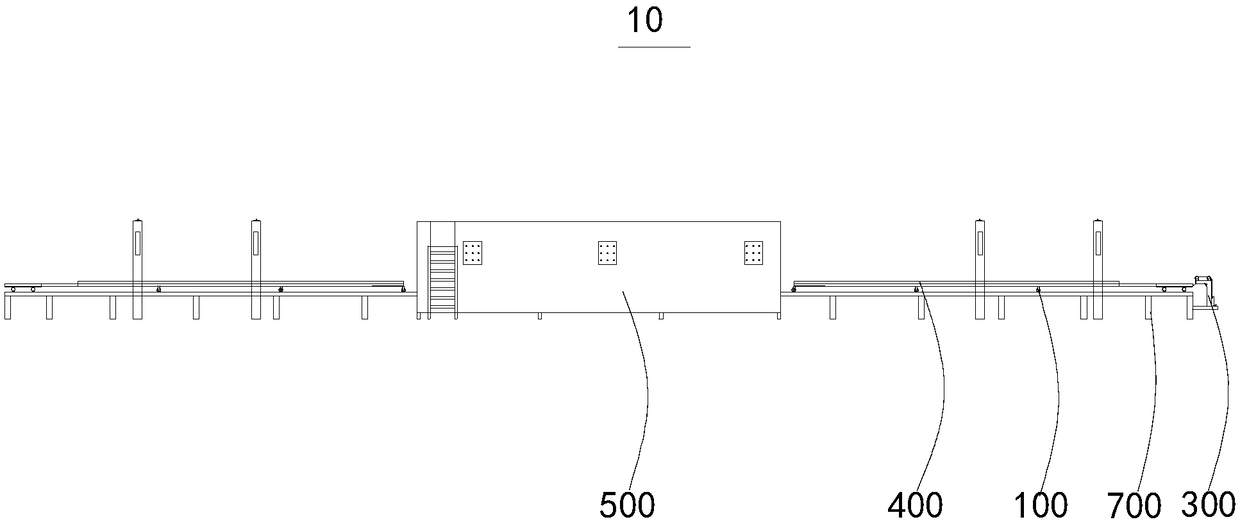

[0071] figure 1 Provide the first structural schematic diagram of the transfer machine 10 for the embodiment of the present invention, specifically show the overall schematic diagram of the transfer machine 10;

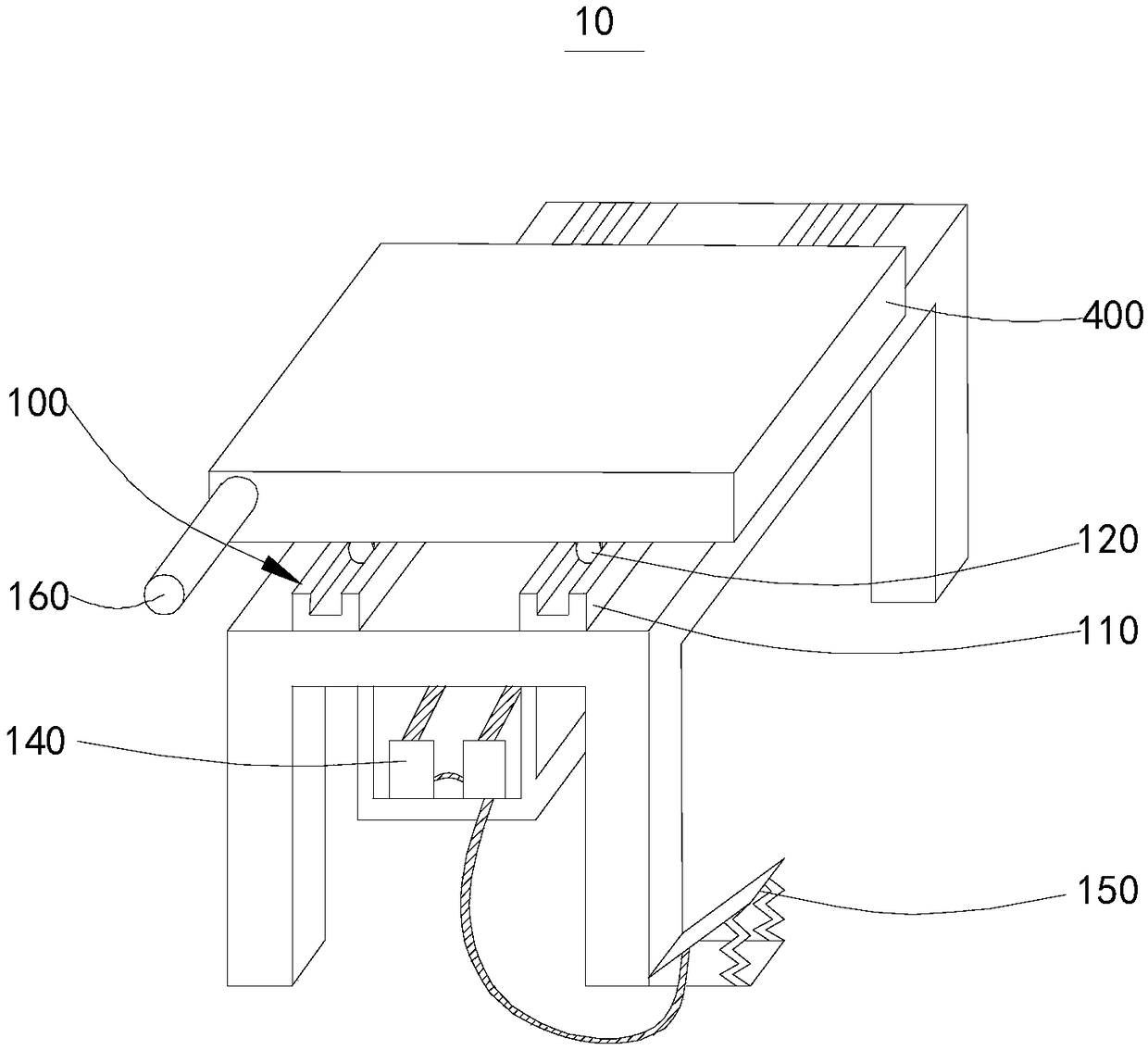

[0072] figure 2 A second structural schematic diagram of the transfer machine 10 is provided for the embodiment of the present invention, specifically showing a schematic diagram of the transfer machine track group 100 and other parts included in the transfer machine 10;

[0073] image 3 for figure 2 A schematic diagram of the structure of a perspective;

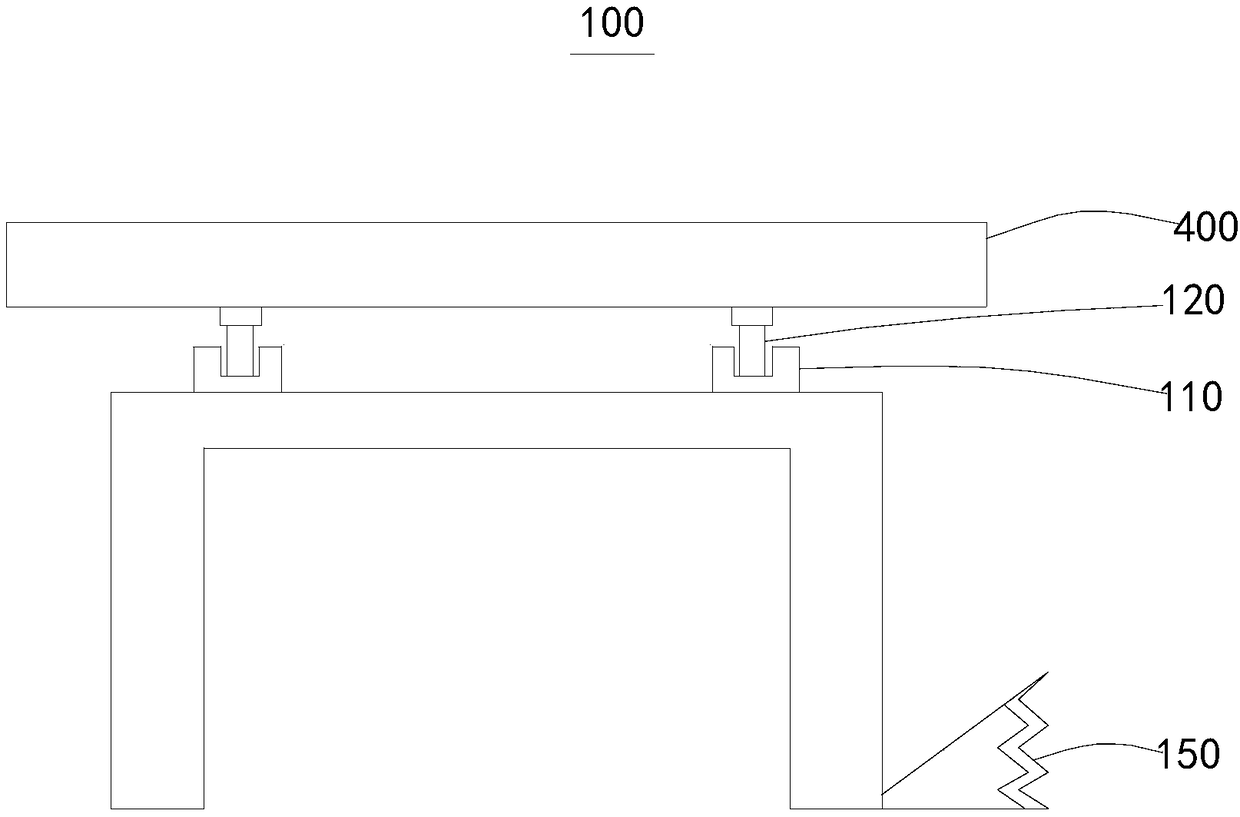

[0074] Figure 4 Provide the first structural schematic diagram of the transfer machine track set 100 for the embodiment of the present invention, specifically showing the connection relationship between the track part 110 and the pulley part 120;

[0075] Figure 5 Provide a schematic structural diagram of the heating furnace door opening and closing group 200 for the embodiment of the present invention, s...

Embodiment 2

[0126] Figure 9 A second structural schematic diagram of the track set 100 of the transfer machine is provided for the embodiment of the present invention, specifically showing a structural schematic view of different arrangements of the pulley fixing parts 130 in the track set 100 of the transfer machine.

[0127] Please refer to Figure 1 to Figure 3 ,Please refer to Figure 5 to Figure 9 , a transfer machine 10 is provided for this embodiment of the present invention. from figure 1 and Figure 5 It can be seen that a transfer machine 10 includes a transfer machine track group 100 , a heating furnace door opening and closing group 200 , a vacuum chamber opening and closing group 300 and a vacuum chamber 400 .

[0128] This embodiment provides a transfer printing machine 10, which is substantially the same as the transfer printing machine 10 of the first embodiment, the difference between the two lies in the arrangement of the track part 110 and the pulley fixing part 13...

Embodiment 3

[0134] Figure 10 A second structural schematic diagram of the vacuum chamber opening and closing group 300 is provided for the embodiment of the present invention. , specifically showing a structural schematic view of the vacuum chamber opening and closing group 300 using the belt 360 .

[0135] Please refer to Figure 1 to Figure 7 ,Please refer to Figure 10 , a transfer machine 10 is provided for this embodiment of the present invention. from figure 1 and Figure 5 It can be seen that a transfer machine 10 includes a transfer machine track group 100 , a heating furnace door opening and closing group 200 , a vacuum chamber opening and closing group 300 and a vacuum chamber 400 .

[0136] This embodiment provides a transfer machine 10 which is substantially the same as the transfer machine 10 of the first embodiment, the difference between the two lies in the connection between the pneumatic part 320 and the first matching part 330 .

[0137] Please refer to Figure 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com