Gap adjustment tooling between headlight and front bumper

A gap adjustment and front bumper technology, which is applied in transportation, packaging, motor vehicles, etc., can solve the problems of uneven gap between headlights and front bumper and affect the appearance quality, so as to improve the assembly quality and the appearance quality of the whole vehicle , shorten the adjustment working hours, and ensure the stability of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

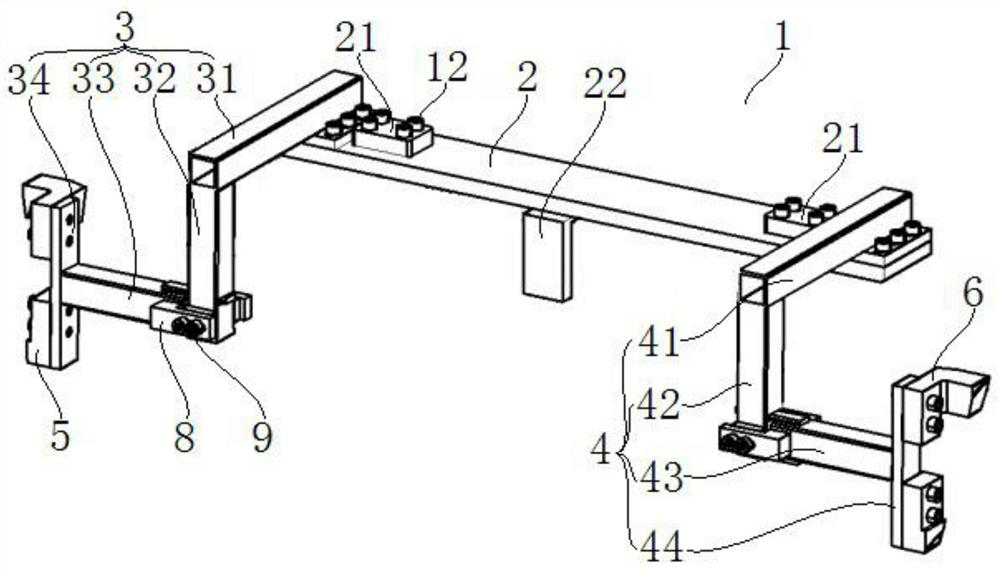

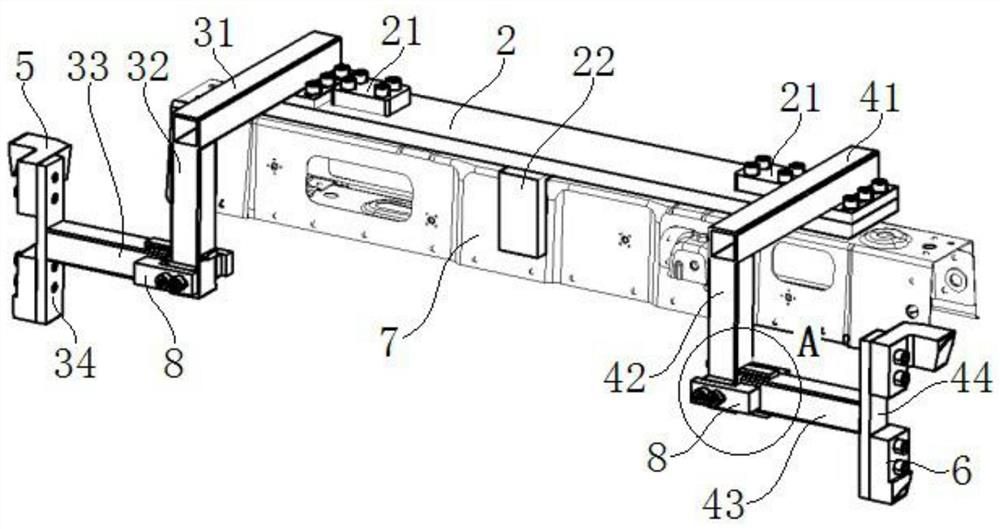

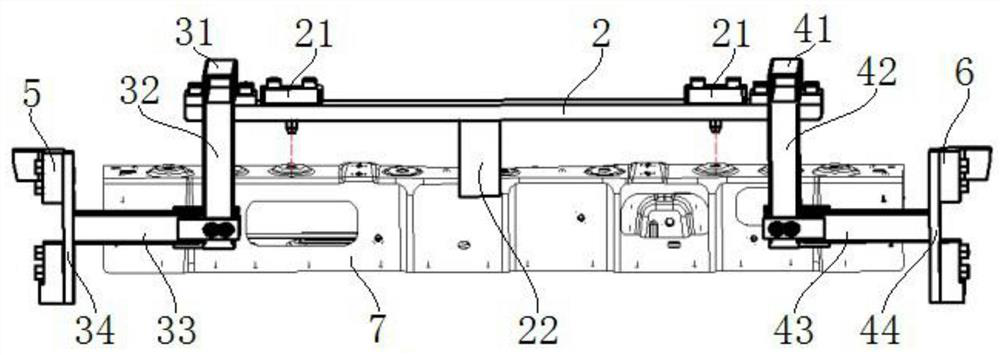

[0029] Embodiment one, see Figure 1 to Figure 7 The gap adjustment tooling between a headlight and a front bumper shown includes a tooling body 1, and is characterized in that: the tooling body 1 includes a positioning plate 2 that cooperates with the front upper member 7, and the rear end is connected to the positioning plate. The left end of 2 is fixedly connected and can adjust the left adjustment bracket 3 of its own width, the rear end is fixedly connected with the right end of the positioning plate 2 and can adjust the right adjustment bracket 4 of its own width, and the left adjustment bracket 3 with the The left headlight locating part 5 which is connected with the left end, and the right headlight locating part 6 which is connected with the right end of the right adjusting bracket 4 are matched. The left adjustment bracket 3 and the right adjustment bracket 4 are symmetrically arranged, and the left headlight positioning part 5 and the right front headlight positioni...

Embodiment 2

[0038] Embodiment 2, a tool for adjusting the gap between the headlight and the front bumper, including the tool body 1, is characterized in that: the tool body 1 includes a positioning plate 2 that cooperates with the front upper member 7, and the rear end is aligned with the positioning plate. The left end of the plate 2 is fixedly connected and can adjust the left adjustment bracket 3 of its own width, the rear end is fixedly connected with the right end of the positioning plate 2 and can adjust the right adjustment bracket 4 of its own width, and the left adjustment bracket 3 The left headlight locator 5 that is connected with the left end of the left headlight, and the right headlight locator 6 that is connected with the right end of the right adjustment bracket 4.

[0039] The positioning plate 2 is provided with a plurality of positioning pieces 21 protruding downwards and cooperating with the front upper member 7 .

[0040] The positioning member 21 includes a connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com