Improved protective film winding equipment

A protective film, an improved technology, applied in the field of improved protective film winding equipment, can solve the problems of not having smoothing function, unable to adjust the moving position of the device, unable to remove dust on the outer surface of the protective film, etc., so as to facilitate the storage work , good dust cleaning work, and the effect of ensuring smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be specifically described below in conjunction with the accompanying drawings.

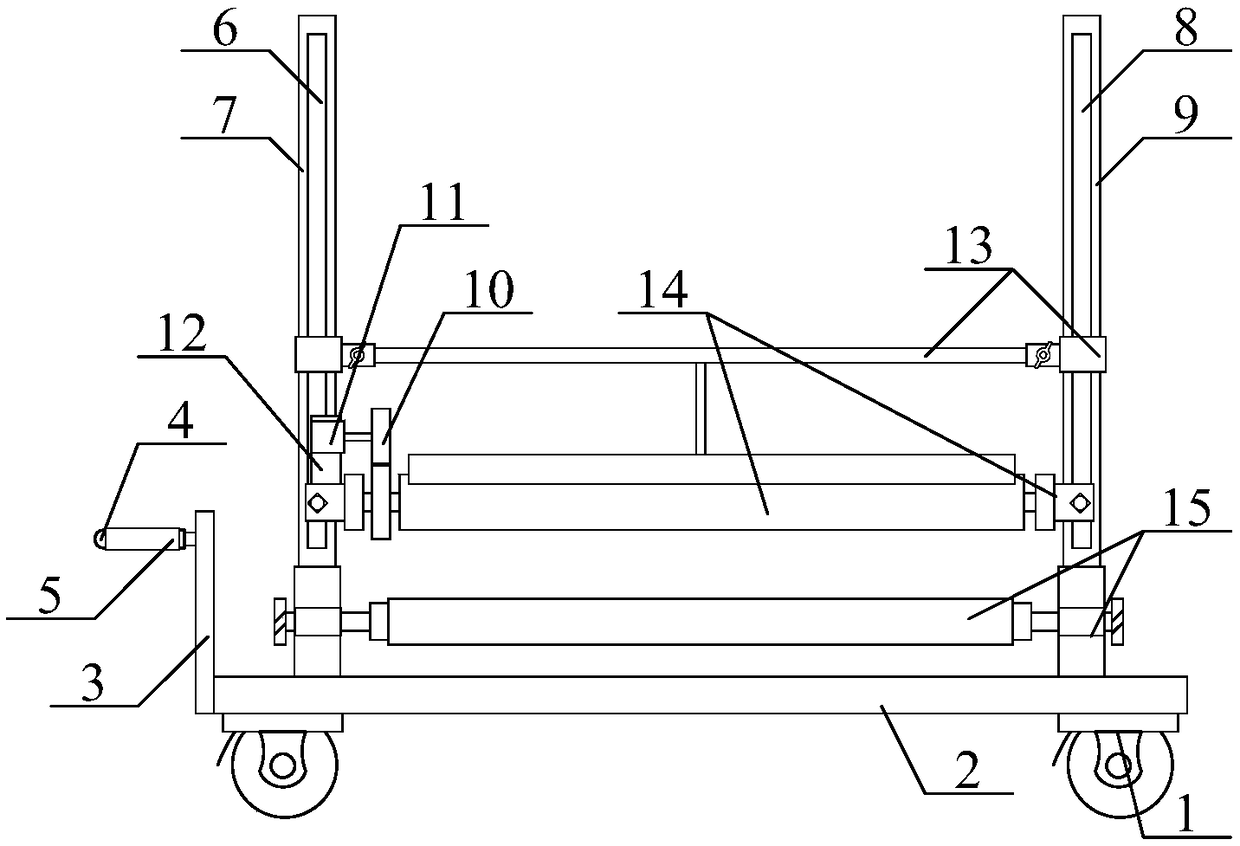

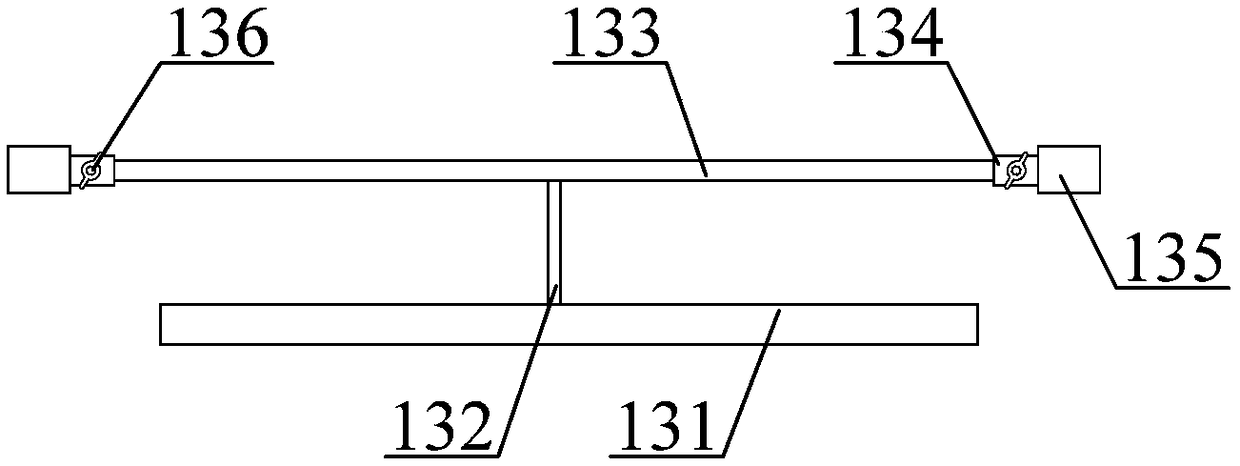

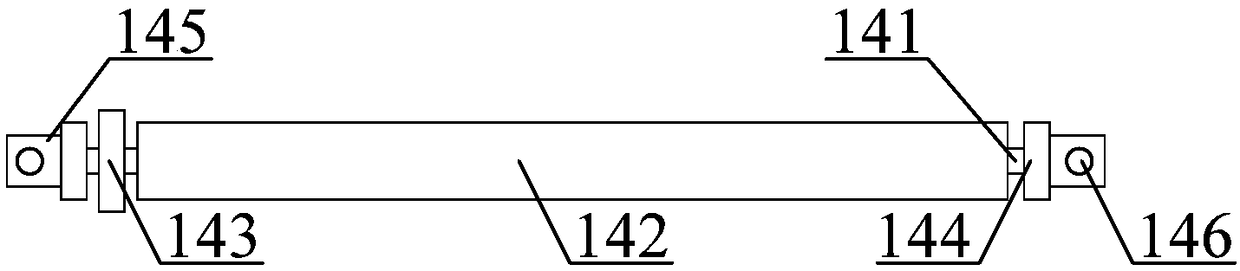

[0043] Such as figure 1 and figure 2As shown, an improved protective film winding device according to the present invention includes a universal wheel 1 with brake pads, a moving base 2, a push rod 3, a push handle 4, an anti-slip sleeve 5, and a first rectangular slot 6 , the first support column 7, the second rectangular channel 8, the second support column 9, the driving gear 10, the driving motor 11, the machine base 12, the adjustable rotating protective film caressing plate structure 13, the adjustable protective film storage roller structure 14 and the dust cleaning auxiliary roller structure 15 on the outer surface of the protective film, the universal wheels 1 with brake pads are installed on the four corners of the bottom of the mobile base 2 by bolts respectively; The left end; the horizontal right end of the push handle 4 is welded on the upper left...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com