Yarn reeling machine

A yarn and silk machine technology, applied in the direction of conveying filamentous materials, thin material processing, transportation and packaging, etc., can solve the problems of inability to adjust the outer circumference, affect work efficiency, and lack of flexibility, and achieve easy installation and Flexible rotation, stable and reliable operation, and the effect of ensuring work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

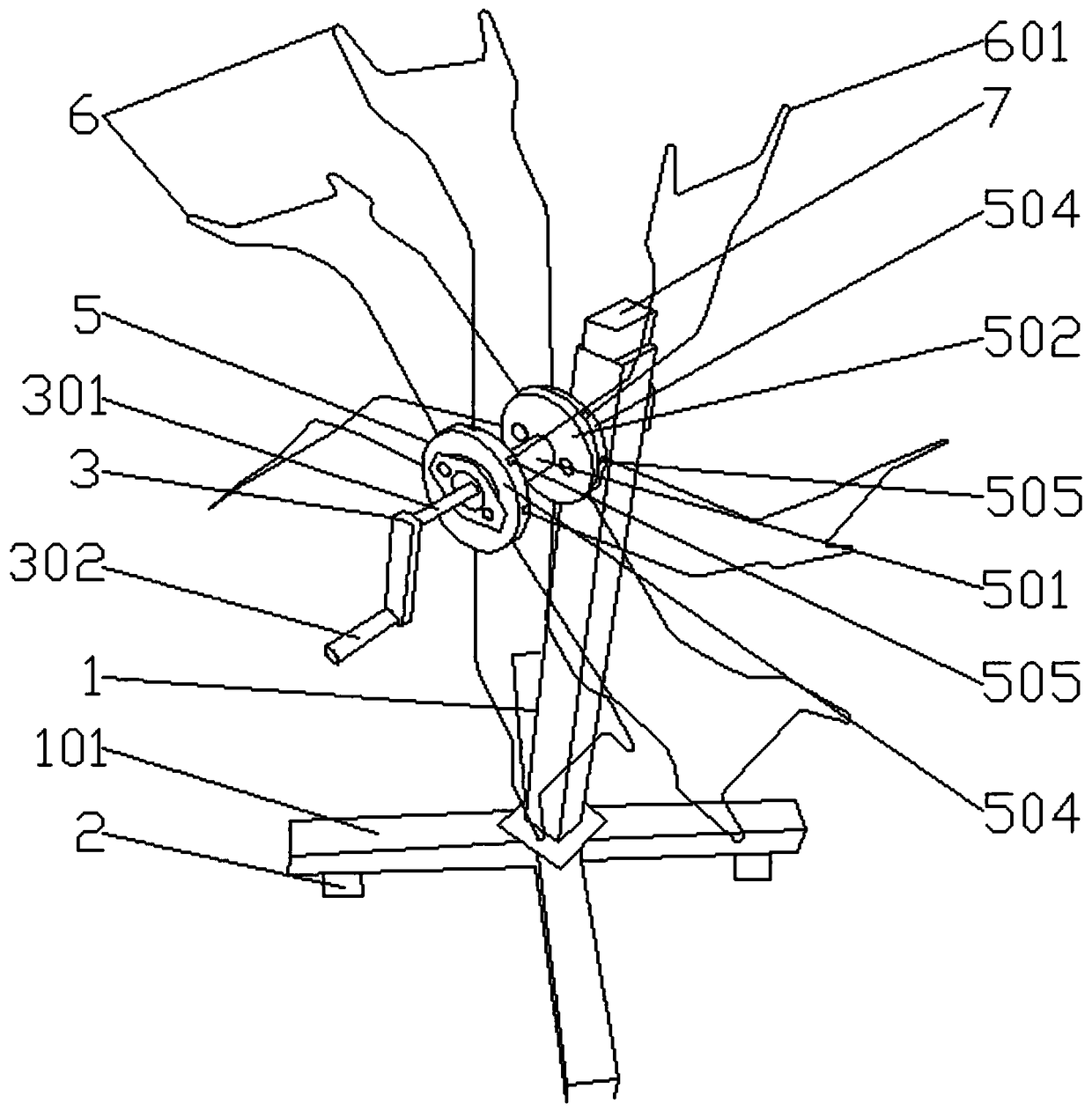

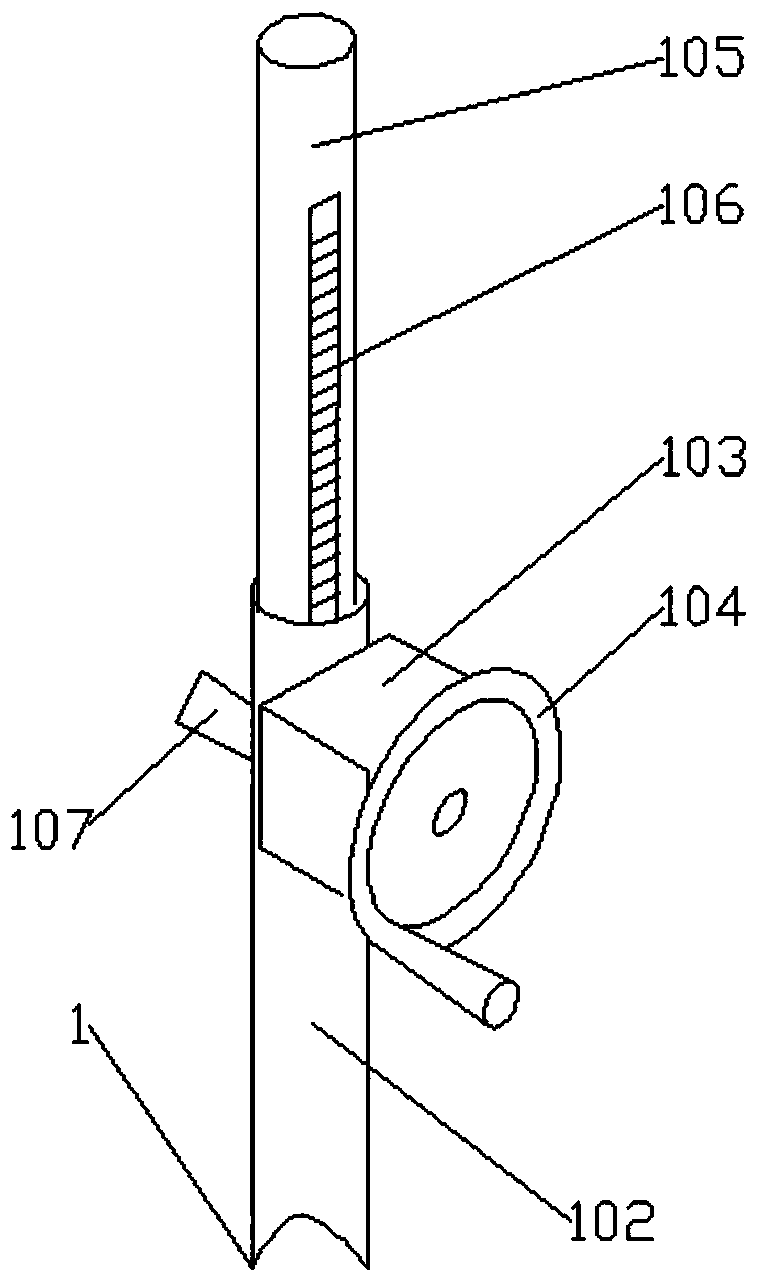

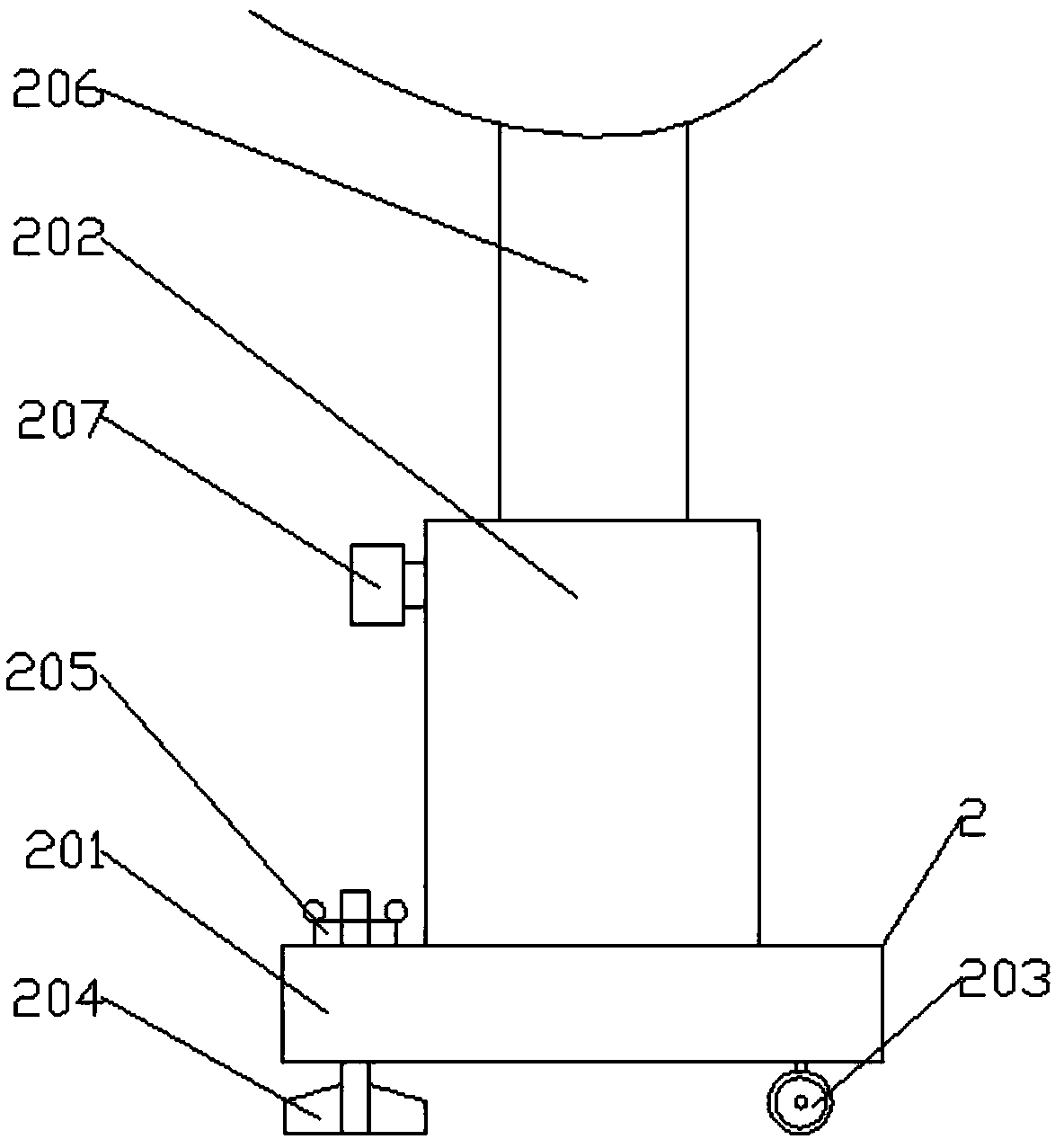

[0043] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 and Figure 9The yarn threading machine shown includes a lifting frame 1, a number of supporting mechanisms 2 arranged at the bottom of the lifting frame, a rotating mechanism 3 arranged on the upper part of the lifting frame, a wheel assembly 5 arranged on the rotating mechanism, and a wheel assembly 5 arranged on the wheel. Several shelving assemblies 6 on the disc assembly; the lifting support includes a base 101 and a support cylinder 102 arranged on the base, the support cylinder is provided with a gear box 103, and the gear box is driven by a hand plate 104, the A lifting rod 105 is arranged inside the supporting cylinder, and a rack 106 is arranged on the lifting rod, and the rack is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com