Get-off multi-way valve for lorry-mounted crane and get-off control system

A truck-mounted crane, multi-way valve technology, applied in mechanical equipment, load hanging components, fluid pressure actuating devices, etc., can solve the problem of inability to optimize the pressure of the drop-off system, the throttling loss of the drop-off valve body, and the flow rate of the valve body. Low problems, to achieve the effect of mitigating and hydraulic shock, valve body optimization, and eliminating hydraulic shock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

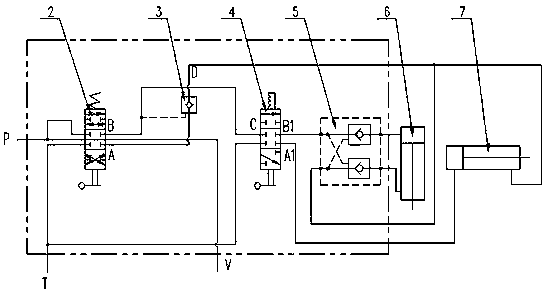

[0028] Such as figure 1 As shown in the figure, a multi-way valve for getting off the truck includes a working valve 2 and a selector valve 4. The work valve 2 is a three-position six-way reversing valve with an O-type neutral function, and the selector valve 4 is a neutral position valve. Function O-type three-position four-way reversing valve, the working oil port B of the working valve 2 is connected to the oil inlet C of the selection valve 4, and the oil inlet C of the selection valve 4 is connected to the working oil port B1 when the selection valve 4 is in the upper position. When the selection valve 4 is in the lower position, its oil inlet C is connected with the working oil port A1, and the working oil port B1 of the selection valve 4 is connected with the two-way hydraulic lock 5 to the hydraulic control unit of the outrigger cylinder 6 rodless cavity The outrigger cylinder 6 has a rod cavity connected to another hydraulic control check valve of the two-way hydrauli...

Embodiment 2

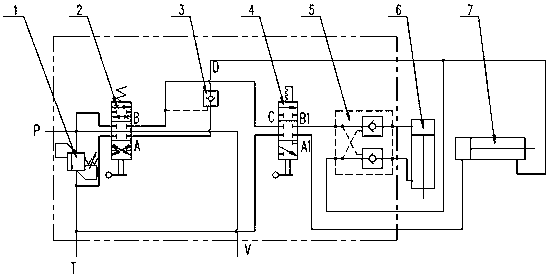

[0035] Such as figure 2As shown, on the basis of Embodiment 1, a relief valve I1 located between the oil inlet P of the alighting multi-way valve and the oil return port T of the alighting multi-way valve is set in the valve body of the getting off multi-way valve, saving Eliminate the hassle of connecting an external relief valve.

Embodiment 3

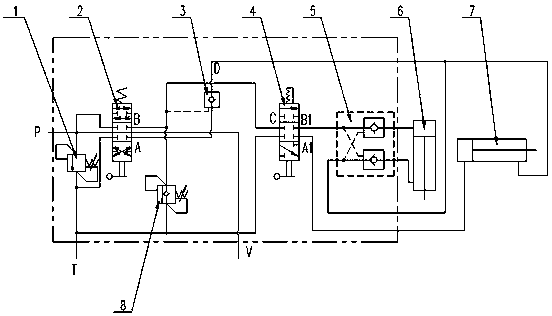

[0037] Such as image 3 As shown, on the basis of Embodiment 1 and Embodiment 2, a secondary relief valve is set in the multi-way valve for getting off the bus, and a secondary relief valve is set between the working oil port B of the working valve 2 and the oil return port T of the multi-way valve for getting off the car. The relief valve II8 is used to control the pressure of the rodless chamber of the outrigger cylinder 6 and the rodless chamber of the horizontal cylinder 7 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com