Preparation method of high-performance chlorinated polyvinyl chloride for injection molding

A chlorinated polyvinyl chloride, high-performance technology, applied in the chemical field, can solve the problems of poor uniformity of CPVC resin particles, large static electricity of CPVC resin particles, and increased waste water treatment costs, etc. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The preparation method of high-performance chlorinated polyvinyl chloride for injection molding comprises the following steps:

[0029] (1) Ingredients

[0030] Install a UV lamp in a 5m³ reactor;

[0031] Add 3800 Kg of 10% hydrochloric acid aqueous solution, 900 Kg of PVC resin with a degree of polymerization of 900, 2.5 Kg of dispersant polyvinyl alcohol, and stir at a speed of 80 r / min to disperse the PVC resin evenly in the water phase.

[0032] (2) Exhaust

[0033] Nitrogen gas was introduced into the reaction kettle to carry out degassing, and the degassing time was 20 minutes.

[0034] (3) Vacuum treatment

[0035] After degassing, the reactor is vacuumed to a pressure of -0.05MPa.

[0036] (4) Chlorination

[0037] A. The first stage of chlorination

[0038] Raise the temperature of the reactor to 80°C, turn on the ultraviolet lamp, and start to feed chlorine gas; the temperature rise rate is 4°C / 15min to 100°C, the rate of chlorine flow is 2.4Kg / min, the...

Embodiment 2

[0053] Using the same method as in Example 1, the intensity of ultraviolet light irradiated by the ultraviolet lamp was changed to 210uW / cm².

Embodiment 3

[0055] Using the same method as in Example 1, the intensity of ultraviolet light irradiated by the ultraviolet lamp was changed to 230uW / cm².

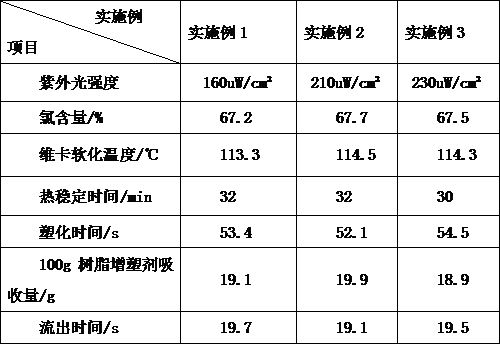

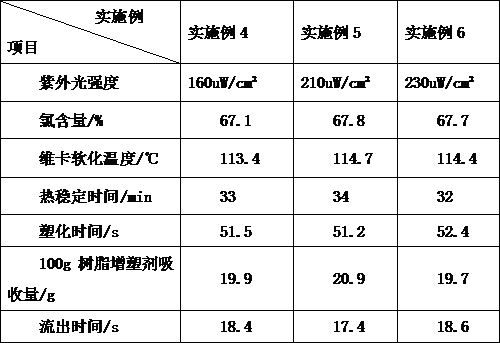

[0056] Table 1 Example 1-3 made CPVC resin performance index test results

[0057]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vicat softening point | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com