Shock absorbing supporting block and vehicle

A technology of supporting blocks and supporting parts, which is applied in the direction of shock absorbers, vehicle parts, springs/shock absorbers, etc., and can solve problems such as poor waterproof, windproof and dustproof effects, inability to ensure the sealing of the car body, vibration and noise, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

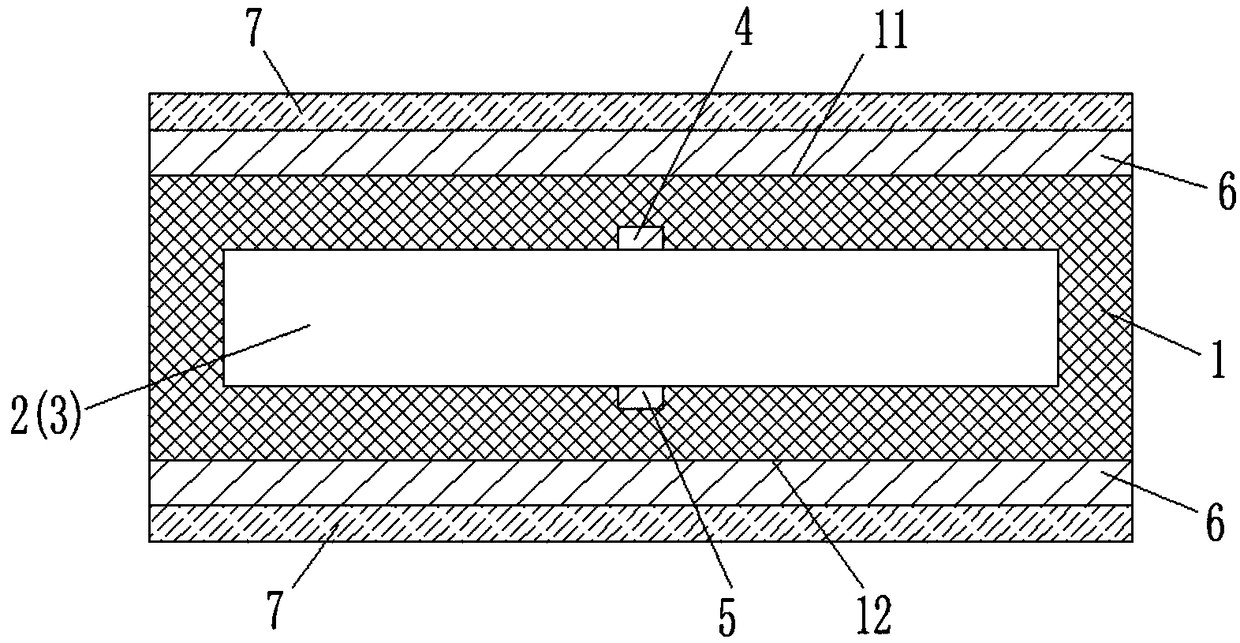

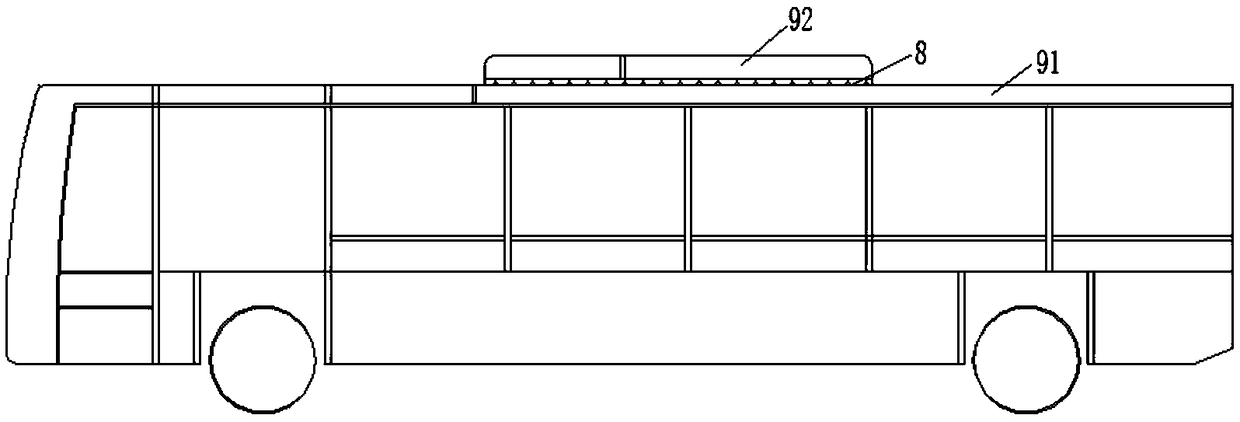

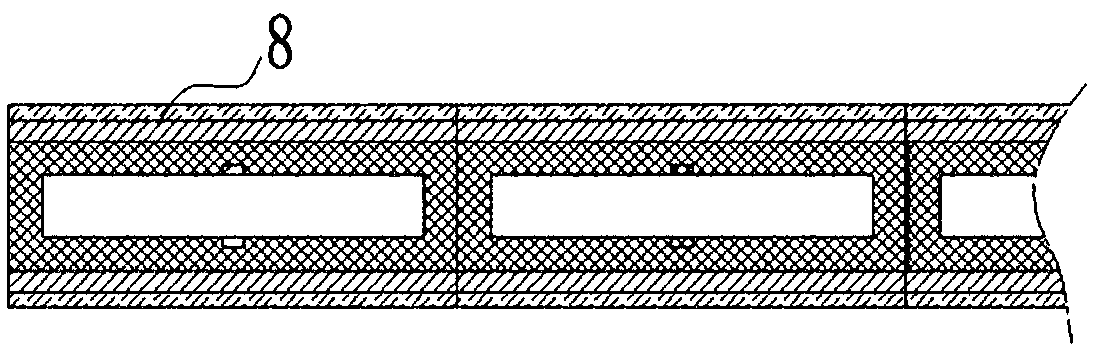

[0022] see in conjunction Figure 1 to Figure 4 As shown, according to an embodiment of the present invention, a shock absorbing support block is provided, which includes an elastic housing 1, and the elastic housing 1 is configured with a cavity 2, and a variable stiffness material 3 is disposed in the cavity 2. In this technical solution, by arranging the variable stiffness material 3 in the elastic shell 1, more specifically, when the variable stiffness material is in liquid phase or gas phase, it is filled into the cavity 2 That is, when the external load is prevented on the shock-absorbing support block, for example, when it is used as a load with vibration such as an air conditioner, it is ensured that the shock-absorbing support block can pass through the difference of the rigidity variable material 3 that it has inside. The adaptive change of the stiffness results in sufficient support stiffness while effectively reducing the vibration transmission, that is, the shock-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com