Economizer water feeding system capable of adjusting inlet smoke temperature of denitration reactor

A technology of denitrification reactor and flue gas temperature, which is applied in the direction of feed water heater, gas treatment, chemical instruments and methods, etc., can solve the problems affecting the flue gas temperature of the denitrification reactor and the denitrification effect of boiler flue gas, and achieve great promotion Application value, simple structure, guaranteed denitrification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

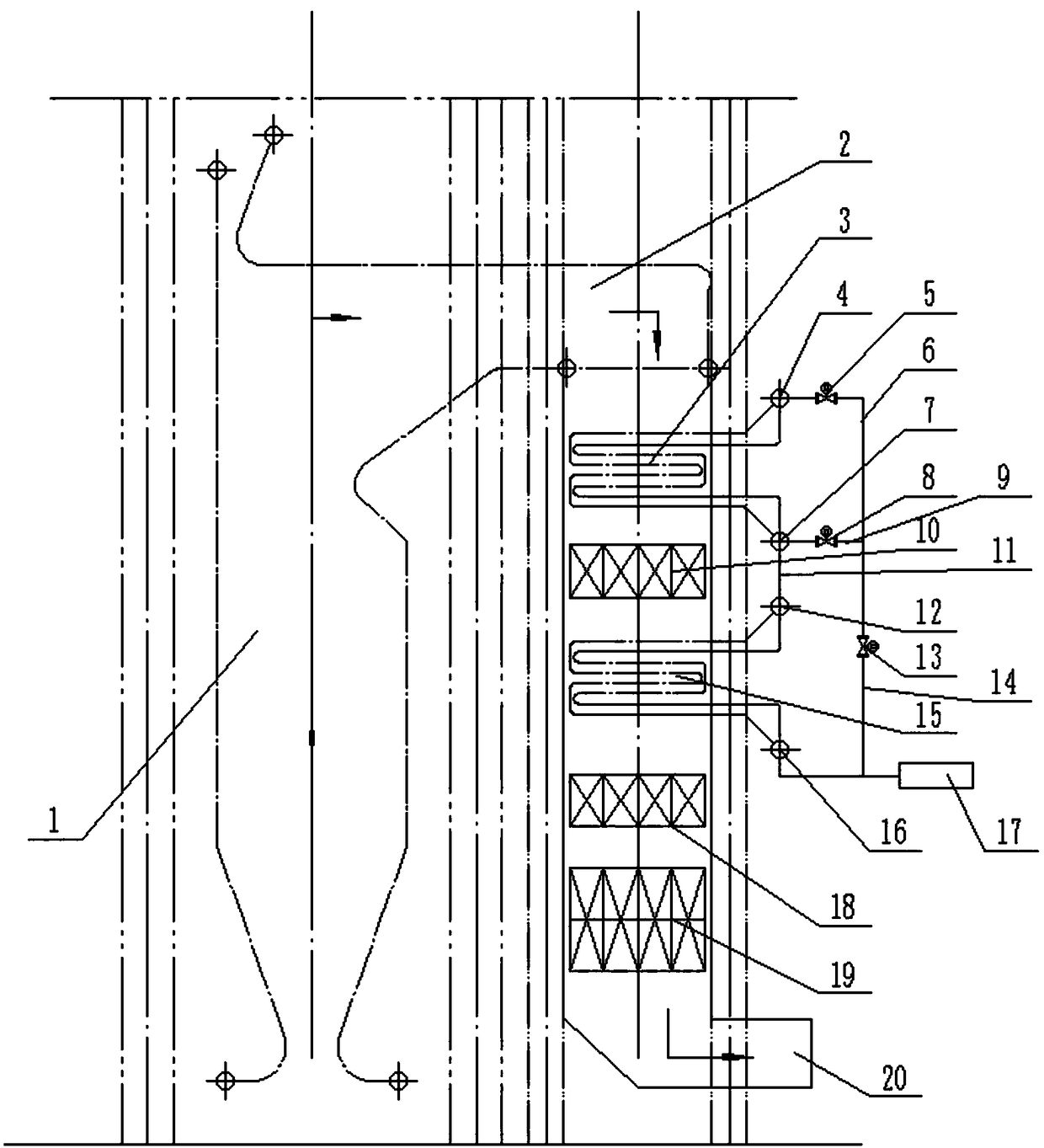

[0018] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the accompanying drawings.

[0019] Such as figure 1 As shown, an economizer water supply system that can adjust the flue gas temperature at the inlet of the denitrification reactor includes a boiler 1 connected to a flue 2, and a high-temperature economizer 3 is arranged in the flue 2 in sequence according to the flue gas conveying direction , denitration reactor 10, low-temperature economizer 15, upper-level air preheater 18, and lower-level air preheater 19. The boiler flue gas of the present invention enters the flue 2 from the boiler 1 and flows through the high-temperature economizer 3 to release heat to reach a suitable temperature. The temperature enters the denitration reactor 10 for denitration reaction. When the operating load of the boiler 1 changes, the temperature of the flue gas entering the denitration reactor 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com