Urban sewage strengthening treatment method in cold area based on multi-point feed water adjustment

A technology for cold area and urban sewage, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. The problem of high operating costs can save construction costs, reduce nitrate concentration, and increase residence time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

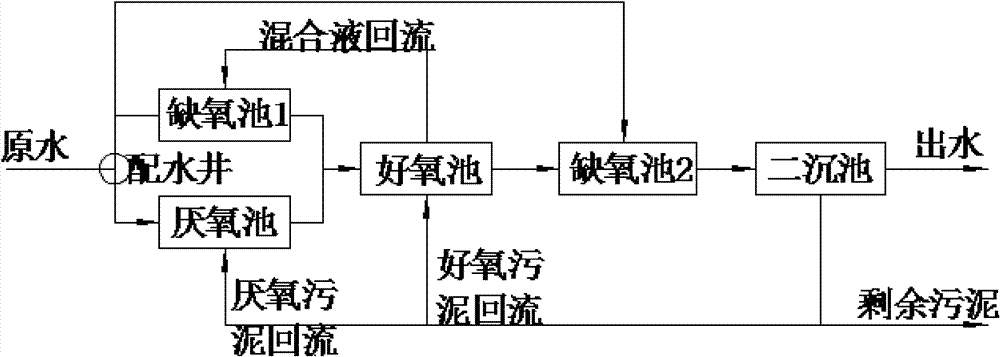

[0023] Specific implementation mode one: combine figure 1 As shown, the enhanced treatment method for urban sewage in cold regions based on multi-point water inflow regulation in this embodiment is carried out in the following steps: 1. Preliminary sedimentation of sewage, with a hydraulic retention time of 0.5 to 1.0 h, and then the primary sedimentation tank is passed through the water distribution well. The effluent is divided into two or three parts for distribution; 2. The effluent mixture of the anaerobic tank and the anoxic tank 1 enters the aerobic tank at the same time as the 30% to 50% return sludge at the head end of the aerobic tank, and the hydraulic retention time is 4.0- 6.0h, the effluent from the aerobic tank enters the anoxic tank 2, the hydraulic retention time is 0.5-1.0h, the effluent from the anoxic tank 2 enters the secondary sedimentation tank for mud-water separation after falling water, the hydraulic retention time is 2.0-3.0h, and the dissolved oxygen...

specific Embodiment approach 2

[0033]Embodiment 2: The difference between this embodiment and Embodiment 1 is that in Step 1, the sewage is preliminarily precipitated, and the hydraulic retention time is 0.6-0.9 h. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0034] Specific embodiment 3: The difference between this embodiment and specific embodiment 1 is that in step 1, the sewage undergoes preliminary precipitation, and the hydraulic retention time is 0.8h. Other steps and parameters are the same as those in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com