Ammonia spraying pipeline and denitration ammonia spraying device

A pipeline and nozzle technology, applied in the field of denitrification and ammonia injection devices, can solve the problems of large proportion of flue cross-sectional area, etc., and achieve the effects of improving energy saving effect, effect guarantee, and reducing wear degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

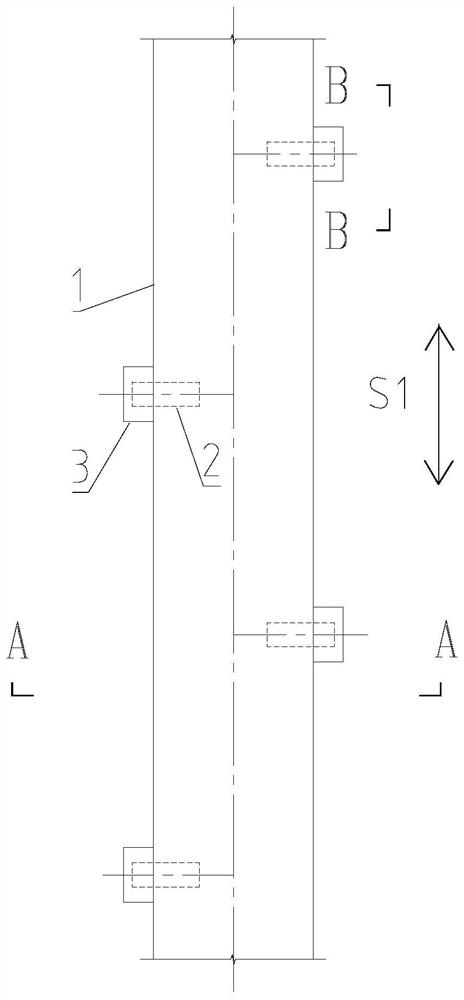

[0041] combine Figure 1-Figure 3 As shown, the ammonia injection pipeline provided by the present embodiment includes:

[0042] Ammonia injection pipe body 1;

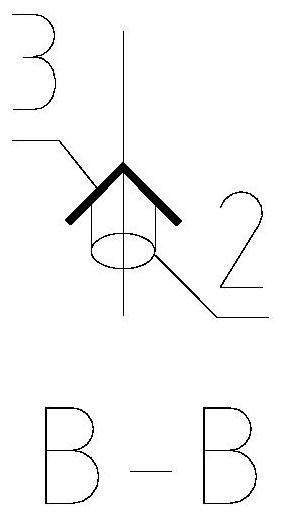

[0043] The nozzle 2 is arranged on the ammonia injection pipeline body 1 and communicates with the inside of the ammonia injection pipeline body 1; and

[0044] The protective angle steel 3 is arranged on the outer surface of the ammonia injection pipe body 1, and is arranged at the position near the wind end of the flue gas flow direction S2 relative to the nozzle 2, and is suitable for at least partially covering the nozzle 2;

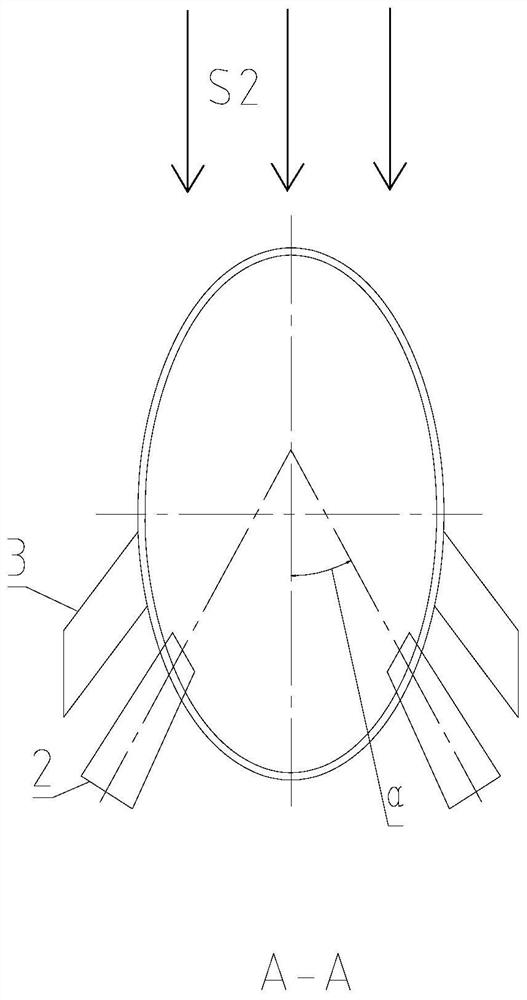

[0045]The cross-section of the ammonia injection pipeline body 1 perpendicular to the ammonia delivery direction S1 is an elliptical structure; and the long axis of the elliptical structure is arranged parallel to the flue gas flow direction S2.

[0046] In the ammonia injection pipeline provided in this embodiment, the cross section of the ammonia injection pipeline body 1 perpendicular t...

Embodiment 2

[0069] combine figure 1 As shown, this embodiment provides a denitrification ammonia injection device, including: the ammonia injection pipeline as described in the first embodiment above, and the ammonia injection pipeline is arranged in the flue.

[0070] The traditional circular cross-section ammonia injection pipes are arranged side by side and parallel inside the flue. The projected area of the pipes occupies almost 20% of the entire cross-sectional area of the flue. The effective cross-section through which the flue gas can pass is reduced, which greatly increases the resistance and energy consumption.

[0071] The denitrification ammonia injection device provided in this embodiment adopts an elliptical ammonia injection pipeline and the long axis of the elliptical structure is arranged parallel to the flue gas flow direction S2, thereby replacing the traditional circular section. In the case of completely equal cross-sectional areas, The ammonia injection flow rate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com