Integrated waste disposal and conversion device

A waste treatment and conversion device technology, applied in the direction of incinerators, gas fuels, combustion methods, etc., can solve the problems of insufficient combustion of combustible gases, full utilization of unfavorable energy, etc., and achieve fast efficiency, stable temperature, and smooth flow of gas Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

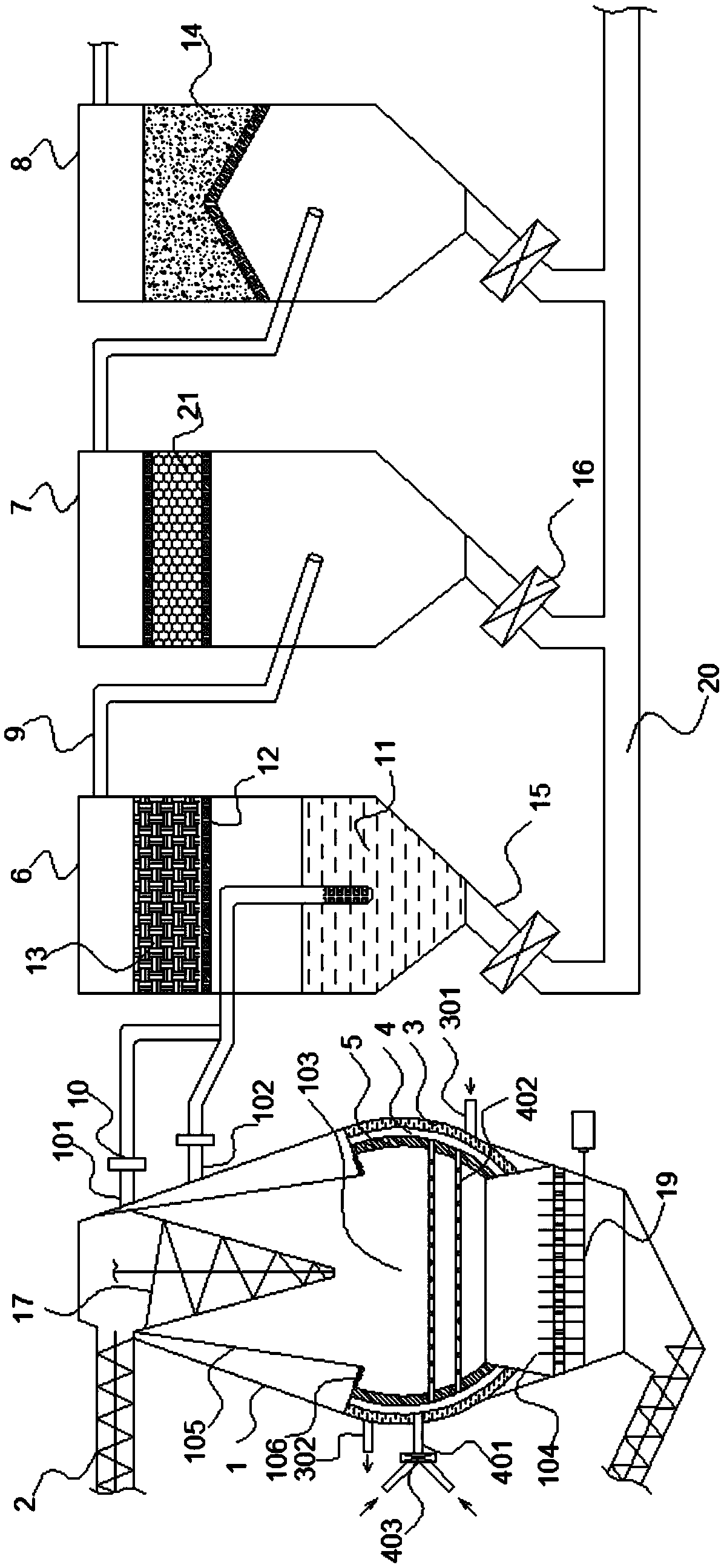

[0037] Such as figure 1 As shown, the integrated garbage treatment and conversion device in this embodiment includes a treatment unit and a purification unit;

[0038] The processing part includes a sealed processing furnace 1, the upper end of the side of the processing furnace is fixedly provided with a screw conveyor 2 for feeding, and the upper end of the side of the processing furnace is also respectively provided with a first gas outlet 101 and a second gas outlet. an air outlet 102, the first air outlet 101 is located above the second air outlet 102;

[0039] The middle section of the processing furnace 1 is a garbage disposal area 103, and the inner wall of the middle section area of the processing furnace 1 is respectively provided with a cooling water layer 3, a gas-supporting layer 4 and a refractory brick layer 5 from the outside to the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com