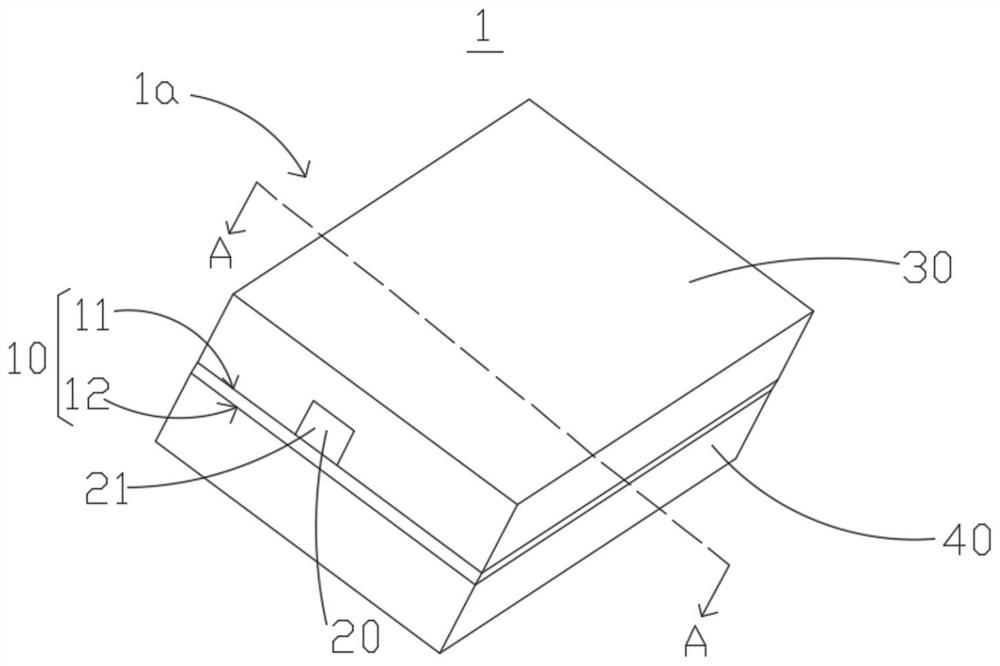

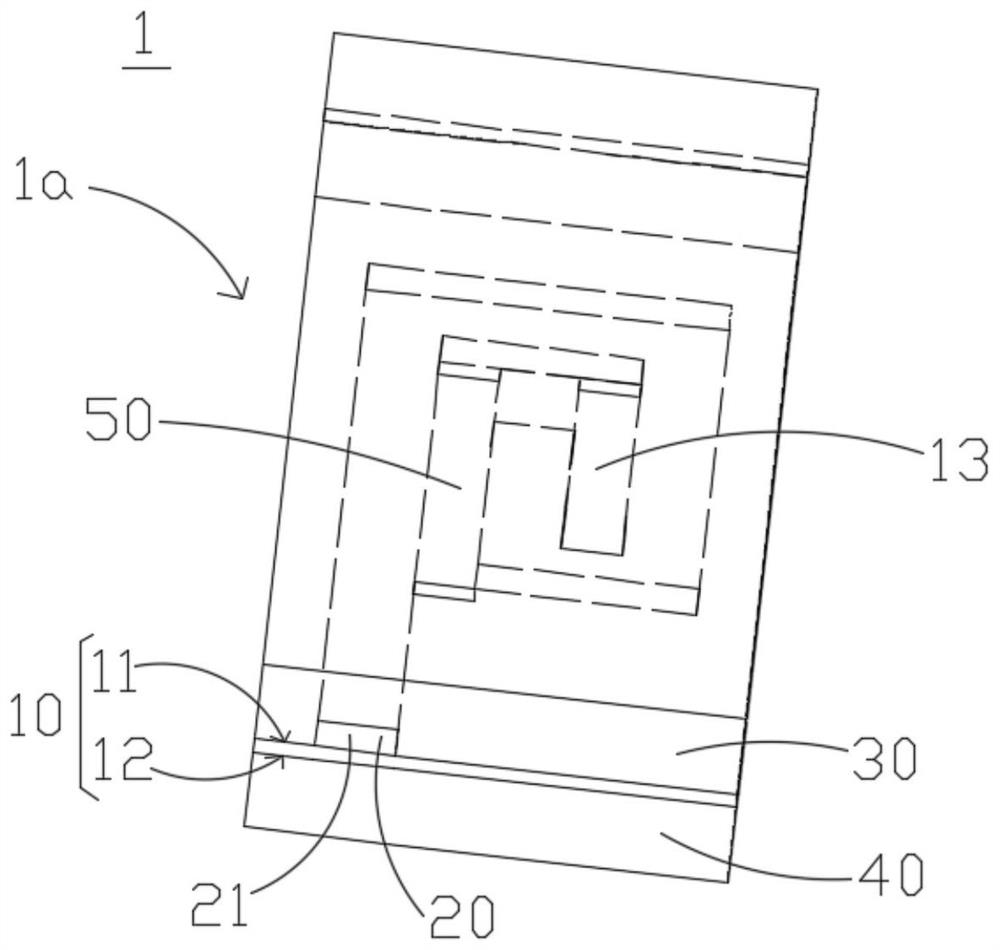

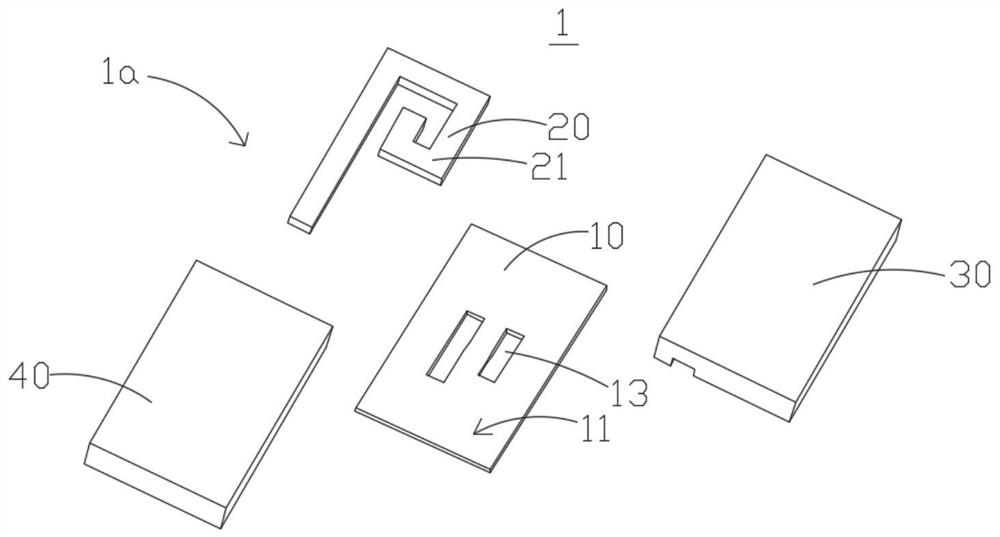

Circuit board assembly and production method thereof, and electronic equipment

A technology of circuit board components and components, which is applied in the direction of printed circuit manufacturing, circuits, electrical components, etc., can solve the problems of reducing inductance, etc., and achieve the effects of reducing magnetic resistance, increasing inductance value, and reducing size and area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The following are preferred embodiments of the application. It should be pointed out that those skilled in the art can make some improvements and modifications without departing from the principle of the application, and these improvements and modifications are also considered as the present invention. The scope of protection applied for.

[0044] Before introducing the technical solution of the present application, the technical problems in the related art will be introduced in detail.

[0045] With the continuous development of the times and technology, the trend of miniaturization of electronic equipment continues to develop. Therefore, the electronic hardware in the electronic equipment is also constantly changing towards the trend of miniaturization and high density. For example, the area and size of circuit boards have decreased dramatically, but with the continuous increase in the functions of electronic equipment, the number of electronic components required to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com