Micro-fiber extrinsic-type Michelson sound pressure sensor with common optical path structure

A Michelson acoustic and pressure sensor technology, applied in the field of micro-fiber extrinsic Michelson acceleration sensors, can solve the problem that the distance between the fiber collimator and the diaphragm is difficult to control, the distance control of the fiber collimator is difficult, and the optical path difference is consistent. In order to avoid the sensor signal fading, good processing consistency, and reduce processing cost and size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

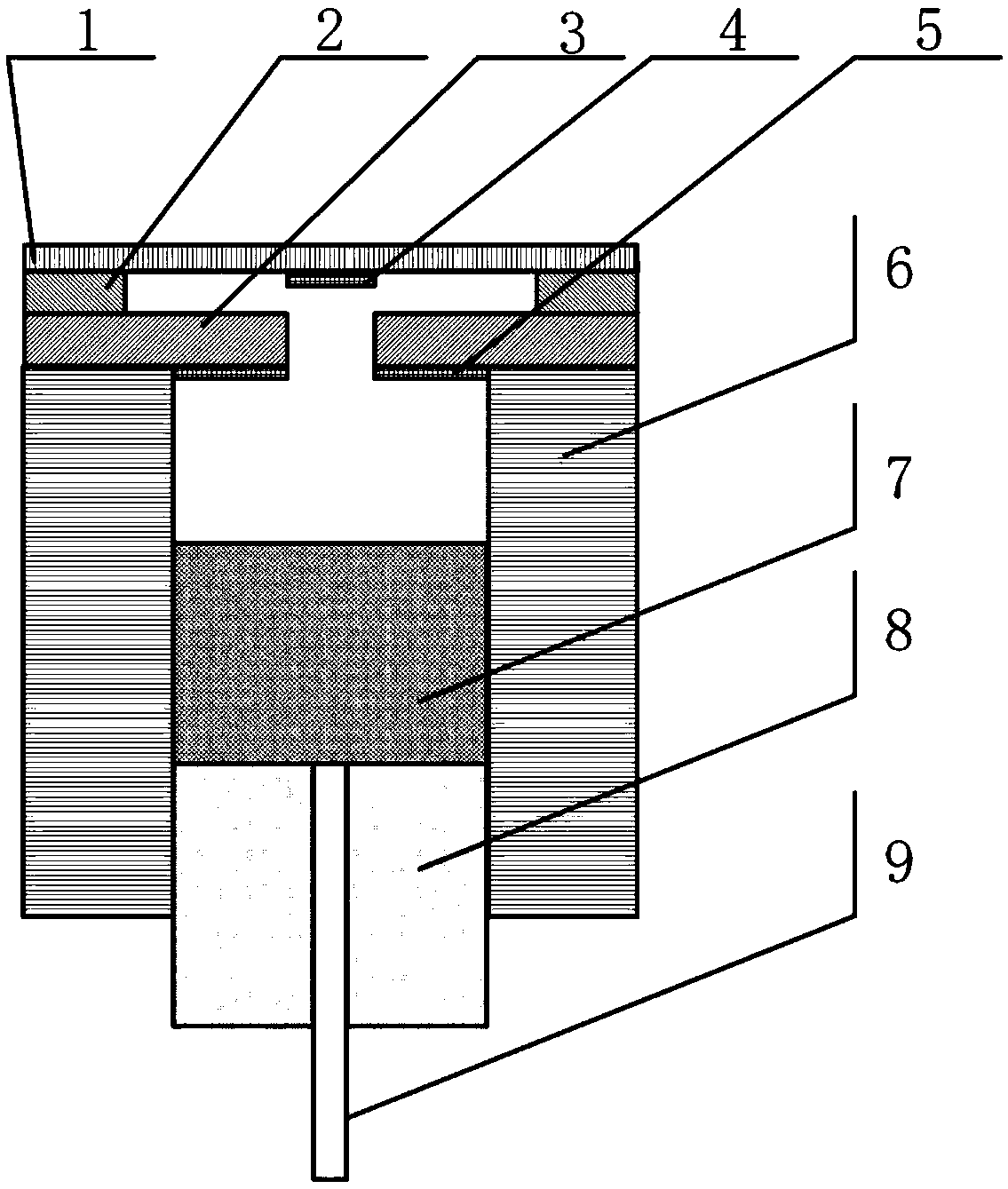

[0019] figure 1 Middle: 1-Sound pressure sensitive diaphragm, 2-diaphragm support structure, 3-sensor base, 4-first anti-reflection film, 5-second anti-reflection film, 6-glass sleeve, 7-optical fiber guide Straight lens, 8-fiber ferrule, 9-single-mode fiber.

[0020] The invention belongs to the technical field of optical fiber sensing, in particular to a miniature extrinsic optical fiber Michelson sound pressure sensor with a common optical path structure.

[0021] Diaphragm fiber optic acoustic pressure sensor has the advantages of small size, light weight, high sensitivity, and no electrical interference. It has achieved rapid development in recent years and has been widely used in ultrasonic testing, underwater acoustic detection, aerospace and other fields. At present, the common membrane fiber optic acoustic pressure sensors are usually based on the Fabry-Pero...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com