Rapid inspection method for construction quality of horizontal joints

A technology of construction quality and detection method, which is applied in the field of non-destructive testing, can solve problems such as low detection efficiency, limited detection space, and long and narrow horizontal joints, and achieve the effects of convenient detection process, improved detection efficiency, and simplified detection process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

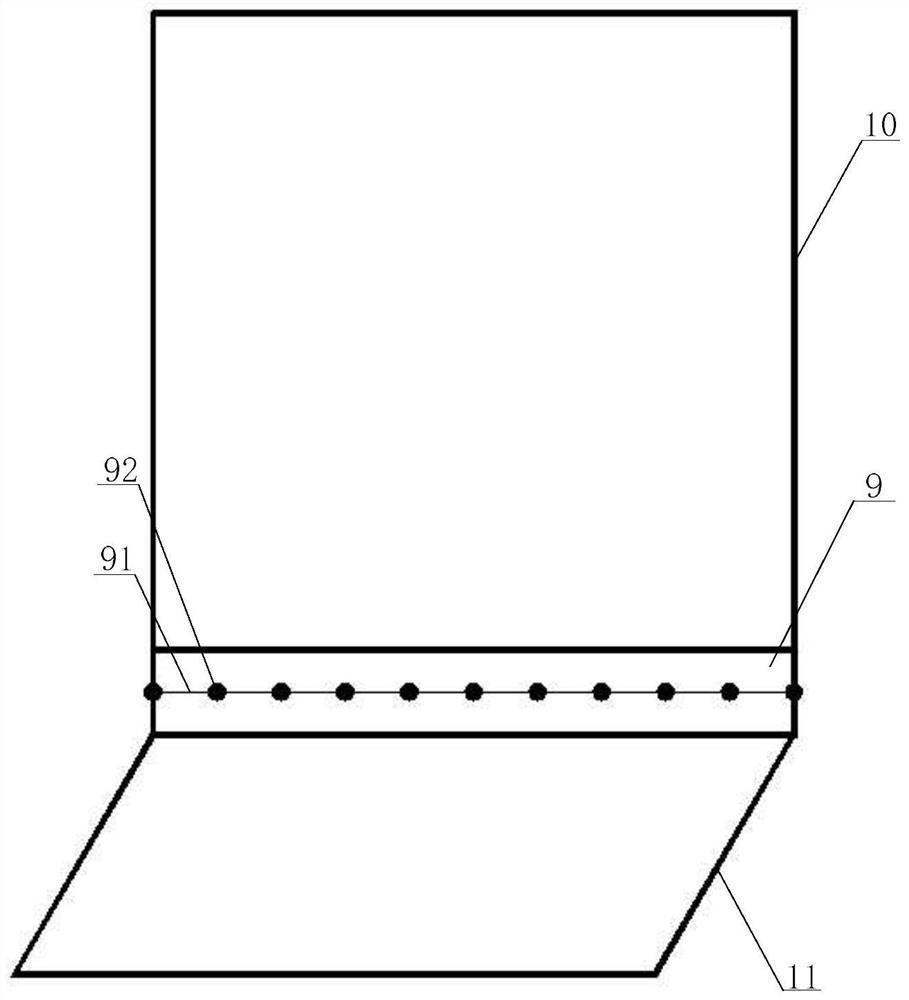

[0029] Below according to the appendix Figure 1 to Figure 3 , the preferred embodiments of the present invention are given and described in detail, so that the functions and characteristics of the present invention can be better understood.

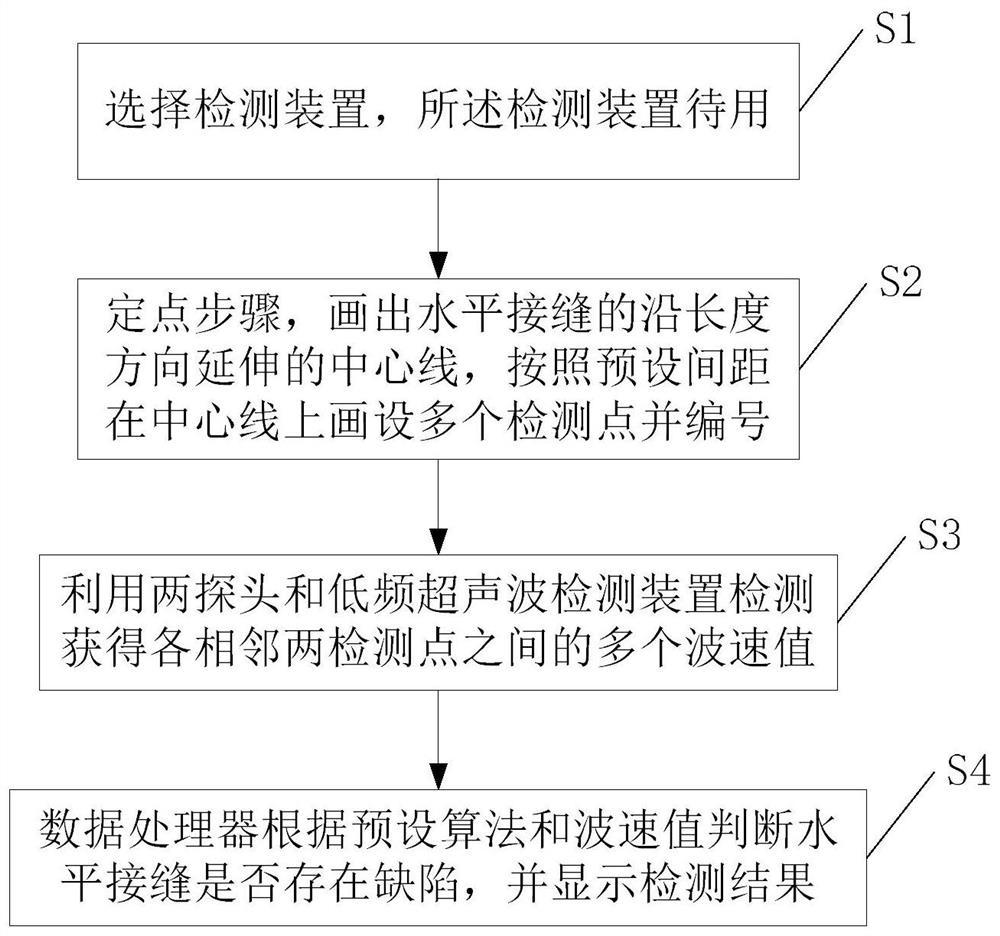

[0030] see Figure 1 to Figure 3 , a method for rapid detection of construction quality of horizontal joints according to an embodiment of the present invention, comprising the steps of:

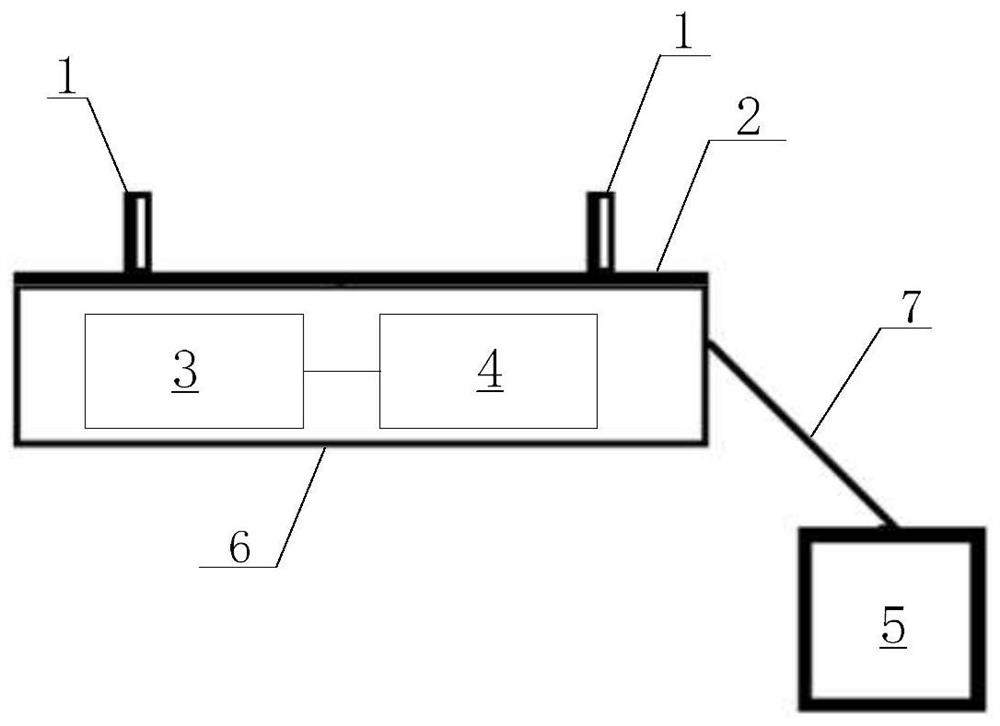

[0031] S1: select a detection device, the detection device is ready to use; the detection device includes two probes 1, a detection surface 2, a low-frequency ultrasonic detection device 3, a data processor 4 and a display screen 5; the detection surface 2 is rectangular, and the two probes 1 is fixed to the detection surface 2 along the length direction of the detection surface 2 according to a preset spacing, and the probe 1 is connected to the low-frequency ultrasonic detection device 3, and the low-frequency ultrasonic detection device 3 and the d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com