An explosion view generation method based on collision detection

An exploded view and collision detection technology, applied in the direction of instruments, geometric CAD, calculation, etc., can solve the problem of low efficiency of the exploded view generation method, and achieve the effect of universality, improved efficiency, and natural explosion separation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

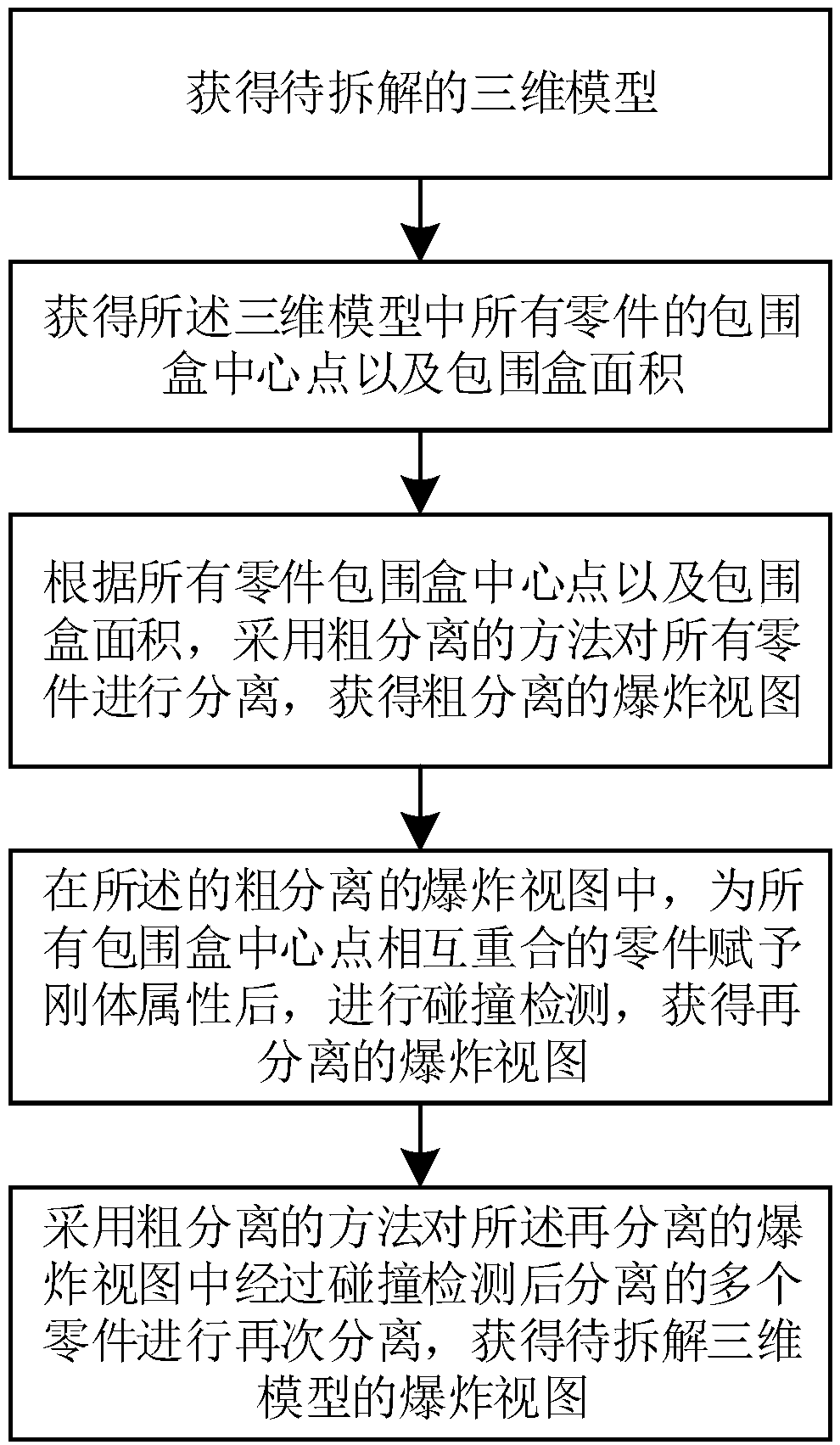

[0045] This embodiment discloses a method for generating an exploded view based on collision detection, and the method includes the following steps:

[0046] Step 1. Obtain the 3D model to be disassembled;

[0047] In this step, the 3D model to be disassembled obtained by CAD, 3DMax and other software is converted into .fbx format and imported to a 3D platform, such as Unity and other platforms.

[0048] Step 2, obtaining the three-dimensional information and the area of the bounding box of each part in the three-dimensional model to be disassembled;

[0049] In this step, the bounding box may be an AABB bounding box, a bounding sphere, an orientation bounding box OBB, a fixed orientation convex hull FDH, and the like.

[0050] As a preferred implementation, the OBB bounding box determines the size and direction of the box according to the geometric shape of the object itself, and the box does not have to be perpendicular to the coordinate axis. In this way, the most suita...

Embodiment 2

[0094] This embodiment discloses a specific generation process of an exploded view based on collision detection, which includes the following steps:

[0095] Step 1. Obtain the 3D model to be disassembled under the Unity platform;

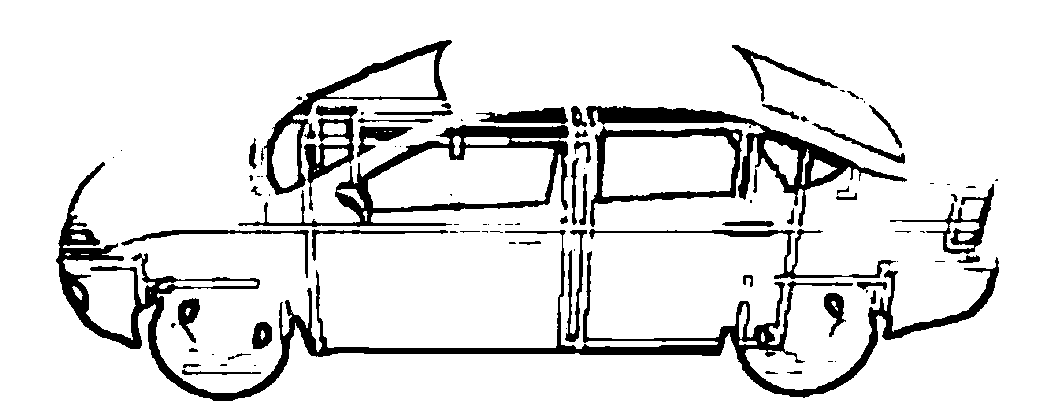

[0096] In this step, use 3DMax software to convert the three-dimensional model into a target format file, and name it Tocus.fbx, the model is as follows figure 2 shown.

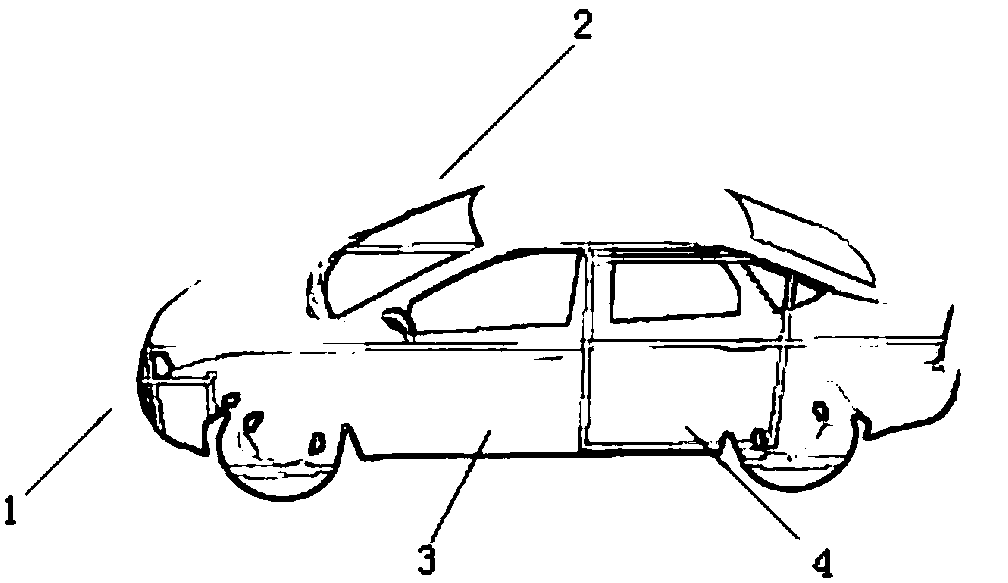

[0097] Step 2. Obtain the center point of the bounding box and the area of the bounding box of all parts in Tocus;

[0098] In this step, each part in the model has a specific positional relationship and specific positional information, and has OBB bounding box information in the three directions corresponding to X, Y, and Z. This information is mainly used to determine the maximum central datum part and the direction of explosion movement, such as image 3 As shown, the bounding box diagram of some components and the corresponding positional relationship of the components. ...

Embodiment 3

[0104] This embodiment discloses a comparison of the effects of a method for generating an exploded view on the Unity platform.

[0105] Comparing the exploded view generation method provided by the present invention with that of LI W, AGRAWALA M, CURLESS B, etc. in the document Automated generation of interactive 3D exploded view diagrams, the objects to be dismantled are all classic turbine models.

[0106] Existing methods obtain such as Figure 6 The shown exploded view takes 1010s, and the method provided by the present invention obtains as Figure 7 The shown exploded view is real-time, and by comparing the two exploded views, it can be seen that the exploded view obtained by the method provided by the present invention is more hierarchical, so the method provided by the present invention is not only for coaxial and containing relationships. The model is feasible, and in the visual effect of the exploded diagram, the separation is more refined.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com