A concrete dam formwork safety construction analysis method based on finite element simulation

An analysis method and technology for concrete dams, applied in design optimization/simulation, instrumentation, geometric CAD, etc., can solve problems such as insufficient formwork stability, improper support measures, casualties, etc., to achieve optimized formwork design, accurate modeling, reliable strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

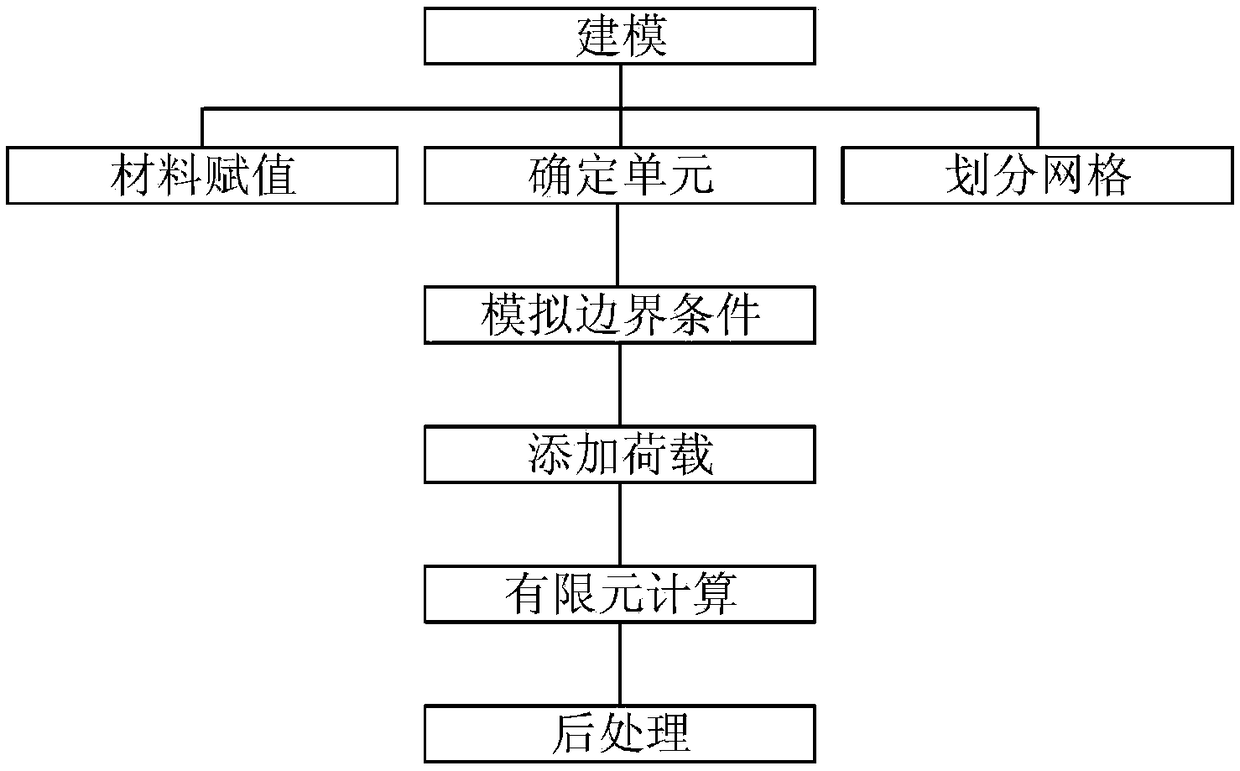

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

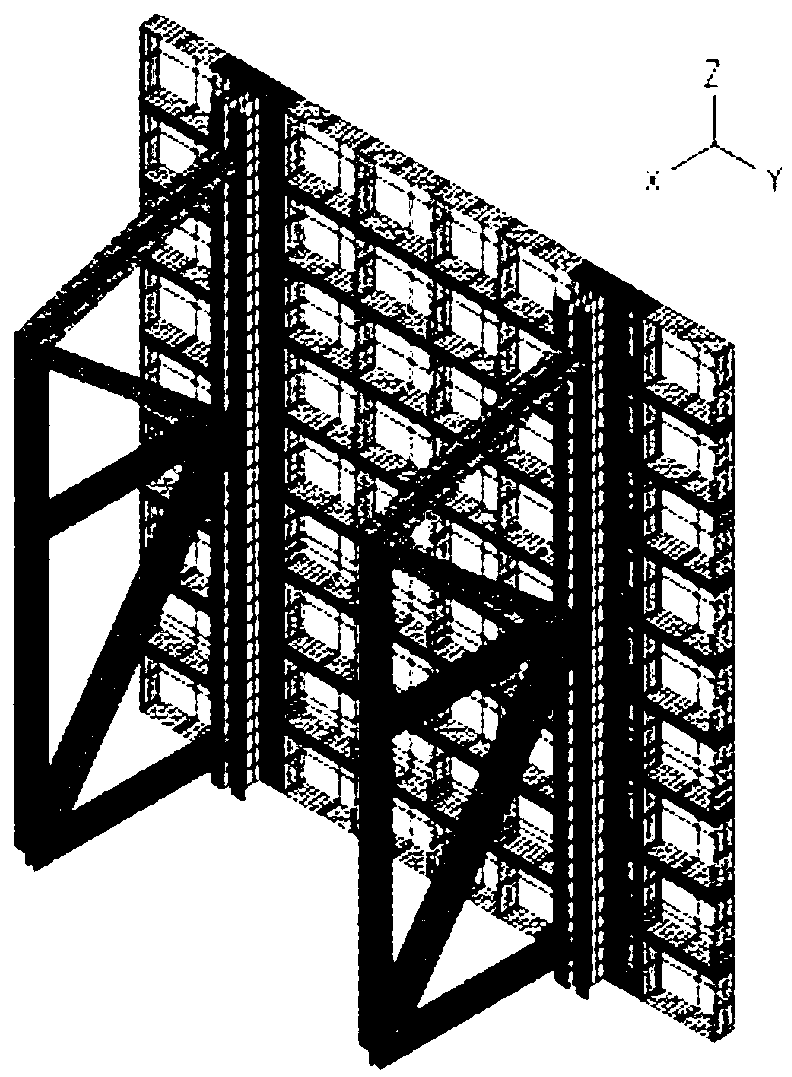

[0031] The present invention is further described below in conjunction with specific embodiment, and specific embodiment is the further description of the principle of the present invention, does not limit the present invention in any way, and the identical or similar technology of the present invention all does not exceed the scope of protection of the present invention.

[0032] In conjunction with the accompanying drawings.

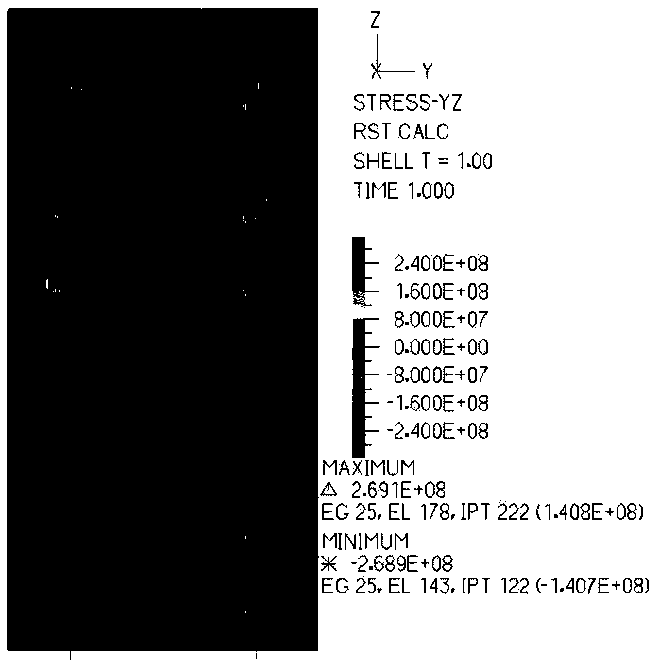

[0033] This example selects the 6.2m assembled large formwork (composed of two 3m*3.1m large formworks) during the construction process of the upstream dam surface elevation 1882.0~elevation 1888.0 of the 4th dam section on the left bank of a power station in the Lancang River. The meta-simulation analysis was carried out to obtain the safety analysis results, and the effective implementation and application were carried out and the measured values of the formwork strain tests during the on-site construction process were used to verify the reliability...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com