Battery box, battery heat dissipation system and electric car

A heat dissipation system and battery box technology, applied to secondary batteries, battery pack components, circuits, etc., can solve the problems of lower vehicle efficiency, poor heat dissipation effect, and large heat dissipation fins, so as to improve heat dissipation effect and ensure Battery life, effective and fast heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

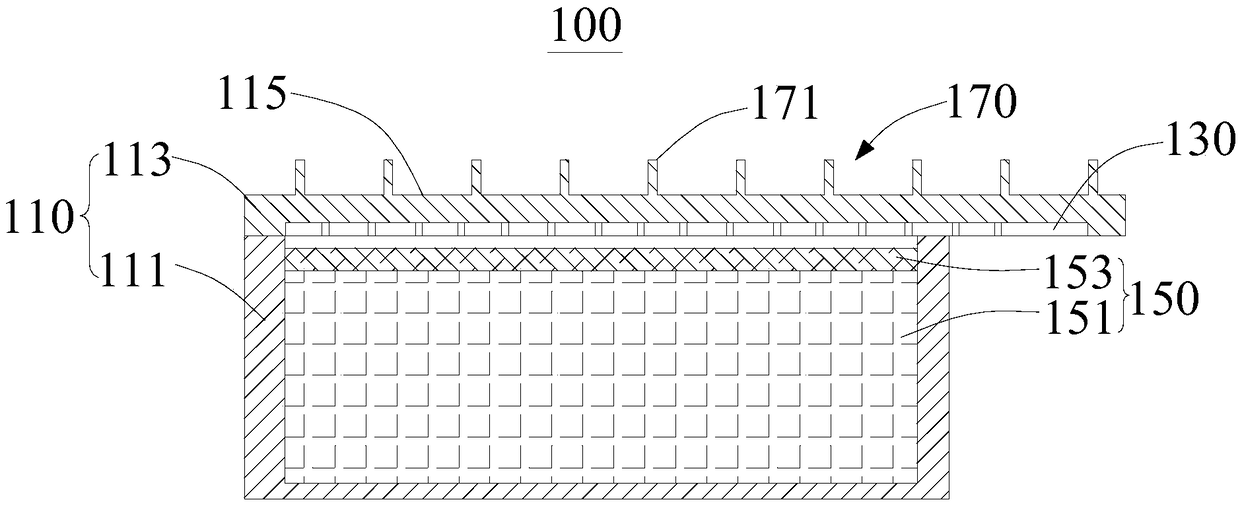

[0037] see figure 1 This embodiment provides a battery box 100, which is installed in the battery compartment of an electric vehicle. The battery box 100 includes a box body 110 and a phase-change heat pipe group 130. A plurality of battery heating components 150 are arranged in the box body 110. The phase-change heat pipe group 130 is fixedly arranged on the inner surface of the box body 110 and is respectively connected to a plurality of electric core heating components 150. The outer surface of the box body 110 opposite to the phase-change heat pipe group 130 has a condensation zone 115, and the condensation zone 115 is provided with a heat dissipation The structure 170 is used for dissipating heat from the condensation area 115 .

[0038] It should be noted that the phase-change heat pipe group 130 has a plurality of phase-change heat pipes, and each phase-change heat pipe uses the phase change of the internal medium to quickly dissipate heat. The heat generated by the ba...

no. 2 example

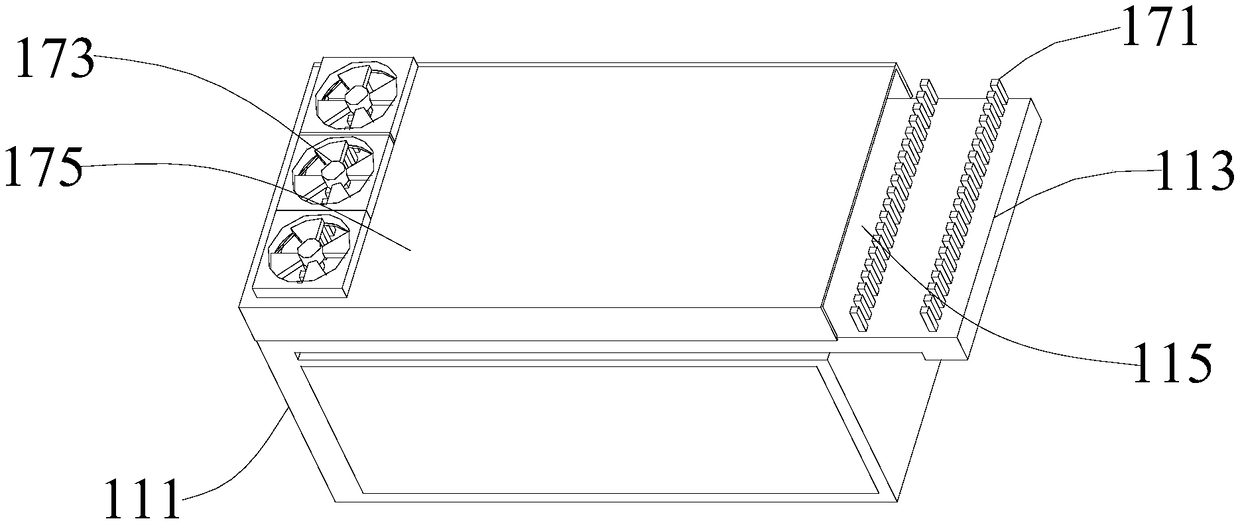

[0047] see figure 2 , this embodiment provides a battery box 100, the basic structure and principle and the technical effect produced are the same as those of the first embodiment, for brief description, the part not mentioned in this embodiment can refer to the first embodiment Corresponding content. Compared with the first embodiment, the difference of this embodiment lies in the heat dissipation structure 170 .

[0048] The battery box 100 includes a box body 110 and a phase-change heat pipe group 130. The box body 110 is provided with a plurality of electric cell heating components 150. The phase-change heat pipe group 130 is fixedly arranged on the inner surface of the box body 110 and generates heat with a plurality of battery cells respectively. The assembly 150 is connected, and the outer surface of the box body 110 opposite to the phase change heat pipe group 130 has a condensation area 115 , and the condensation area 115 is provided with a heat dissipation structur...

no. 3 example

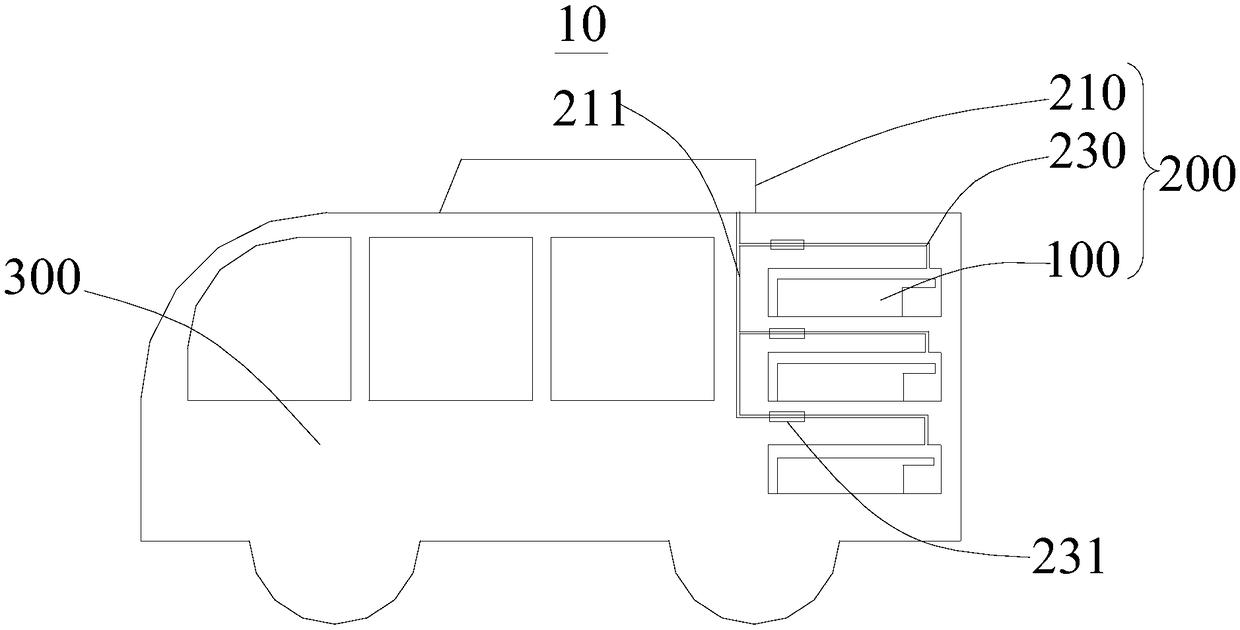

[0056] see image 3 , the present embodiment provides an electric vehicle 10, comprising a vehicle body 300 and a battery cooling system 200, the rear end of the vehicle body 300 is provided with a plurality of battery compartments, the battery cooling system 200 includes an air conditioner 210, a plurality of water cooling pipes 230 and A plurality of battery boxes 100 are respectively arranged in a plurality of battery compartments. The basic structure, principle and technical effects of the battery box 100 are the same as those of the first embodiment. For a brief description, for parts not mentioned in this embodiment, reference may be made to the corresponding content in the first embodiment.

[0057] Each battery box 100 includes a box body 110 and a phase-change heat pipe group 130. A plurality of electric core heating components 150 are arranged in the box body 110. The phase-change heat pipe group 130 is fixedly arranged on the inner surface of the box body 110 and is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com