Straw mulching plant protection equipment for amorphophallus konjac planting

A technology of flower konjac and straw, applied in botany equipment and methods, plant protection, plant protection cover, etc., can solve problems such as delayed timing, difficult control of thickness, and failure to achieve results, so as to reduce ground temperature, prevent burns, and promote early The effect of germination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

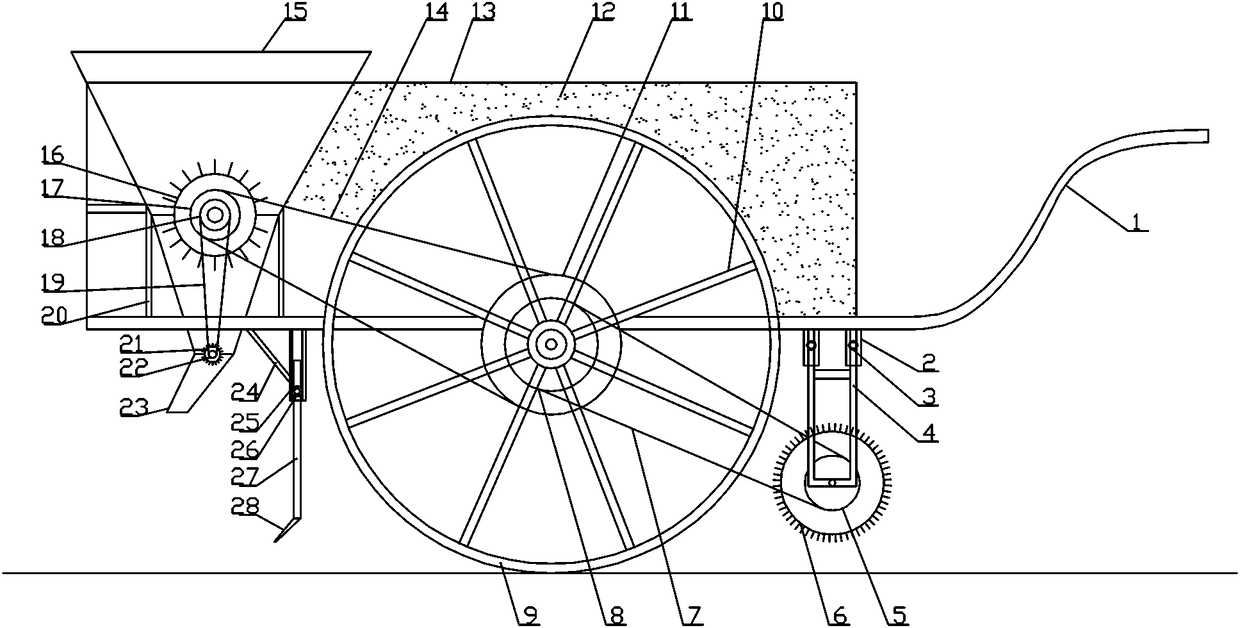

[0027] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0028] see figure 1 , flower konjac planting straw covering plant protection equipment, it includes a cart box 13, the cart box 13 is installed on the top of the wheel 9, the wheel 9 is equipped with spokes 10, the cart box 13 Cart handle 1 is installed at the afterbody; The inside of described cart box 13 is equipped with material hopper 15, and the bottom of described material hopper 15 passes through the bottom plate of cart box 13, and is connected with the lower end at its end. The hopper 23, the first-level raking mechanism and the second-level raking mechanism are respectively installed inside the storage hopper 15 and the lower hopper 23 .

[0029] Further, the first-level raking mechanism and the second-level raking mechanism form belt drive cooperation with the pulley on the wheel 9 through belt transmission respectively. The first-level raki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com