Compressed coconut fruit reduction and embrittlement process

A coconut and embrittlement technology, which is applied in the reduction and embrittlement process of compressed coconut, can solve the problems of inconvenient large-scale industrial production and expensive equipment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The compressed coconut fruit reduction of embodiment 1 and embrittlement process are carried out according to the following steps:

[0024] S1, precooked reduction

[0025] S11: Add compressed coconut raw materials and water into the square pre-cooking tank. The compressed coconut raw material size is 1.5 × 1.5 × 1.5cm. The ratio of compressed coconut and water is controlled so that the compressed coconut can still be immersed in the It is advisable in water; In embodiment 1, the weight ratio of compressed coconut fruit and water is 1:7;

[0026] S12: Add sodium hydroxide to the square precooking tank at a ratio of 0.7wt‰ of coconut fruit after soaking, and stir evenly;

[0027] S13: Use steam to heat the water in the square pre-boiled tank for about 10 minutes, stop using steam, and continue stirring for about 25 minutes (keep the water temperature above 90 degrees during this process, turn on steam to heat up when it is lower than this temperature) and then compress ...

Embodiment 2-10

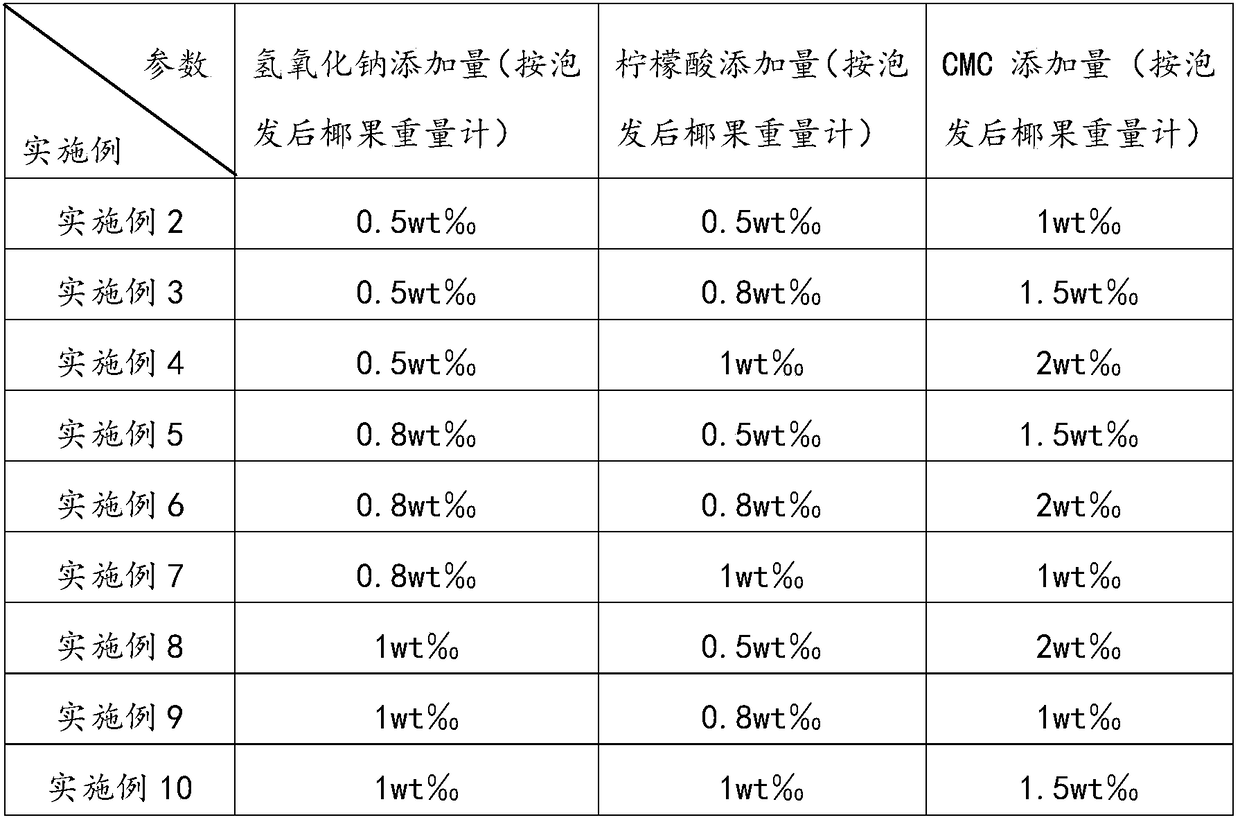

[0033] The difference between embodiment 2 to embodiment 10 and embodiment 1 is listed in the following table:

[0034]

[0035] Test shows that the obtained coconut fruit of embodiment 2 to 10 all has the transparent color and luster that is substantially consistent with embodiment 1, and what eat has brittle feeling, and no slag has no peculiar smell.

[0036] In other embodiments of the present invention, sodium bicarbonate and / or sodium carbonate can be used instead of sodium hydroxide as an alkaline deodorant, sodium citrate, malic acid and / or acetic acid can be used instead of citric acid as an acidic neutralizer, Konjac gum, guar gum, carrageenan and / or gellan gum can be used instead of CMC as embrittlement agents.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com