Production method of water phantom

A production method and water model technology, applied in radiological diagnostic testing/calibration, computerized tomography scanners, echo tomography, etc., can solve problems such as increased production costs, reduced customer credit, and reduced yields, so as to improve product qualification The effect of high efficiency, guaranteed production quality, and high product qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

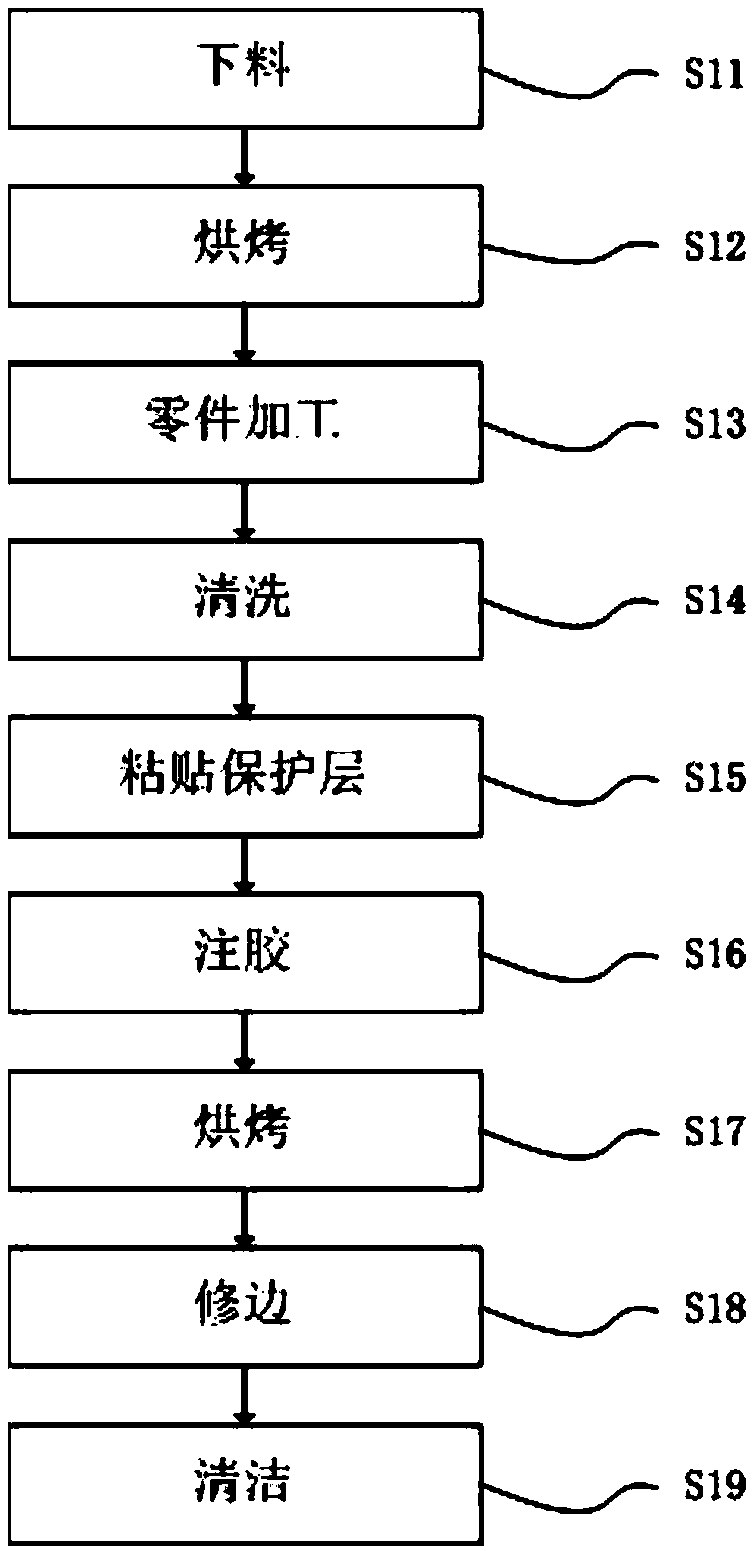

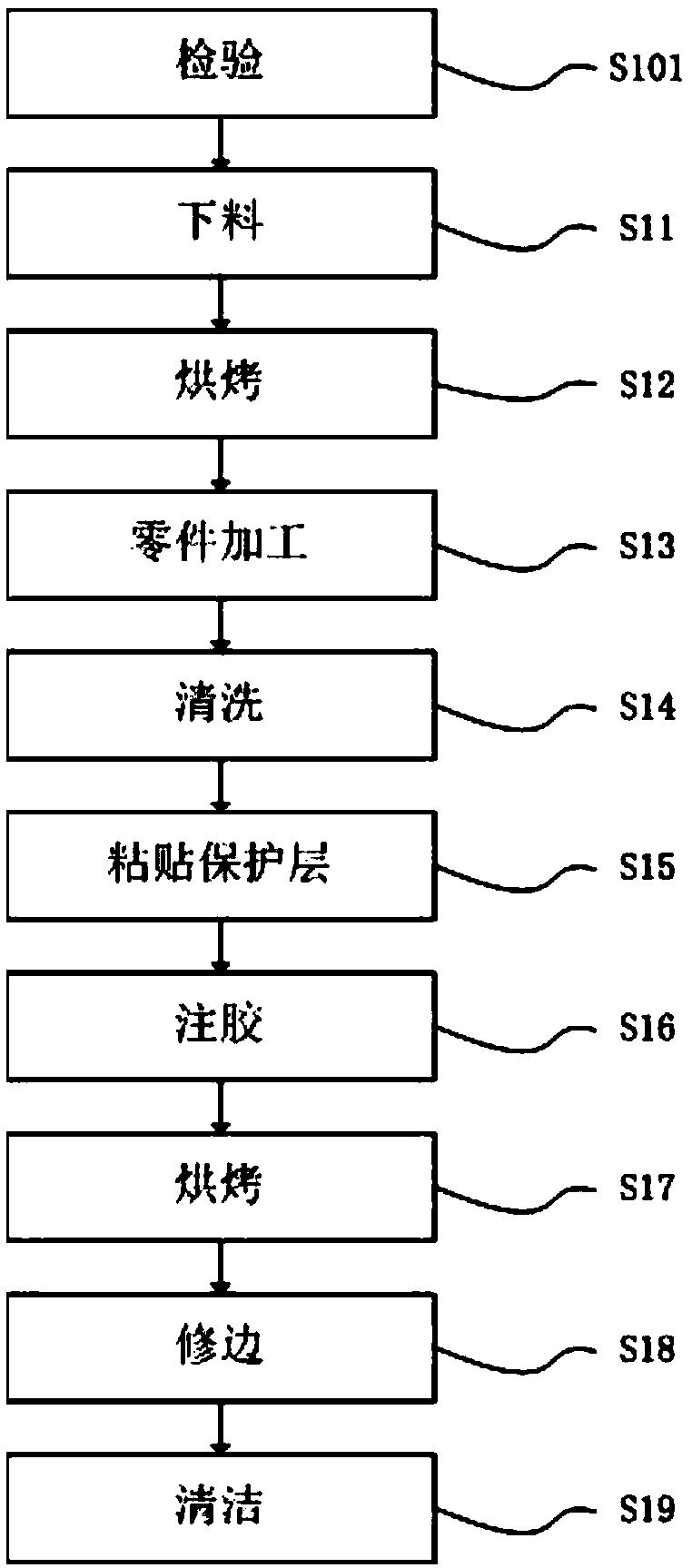

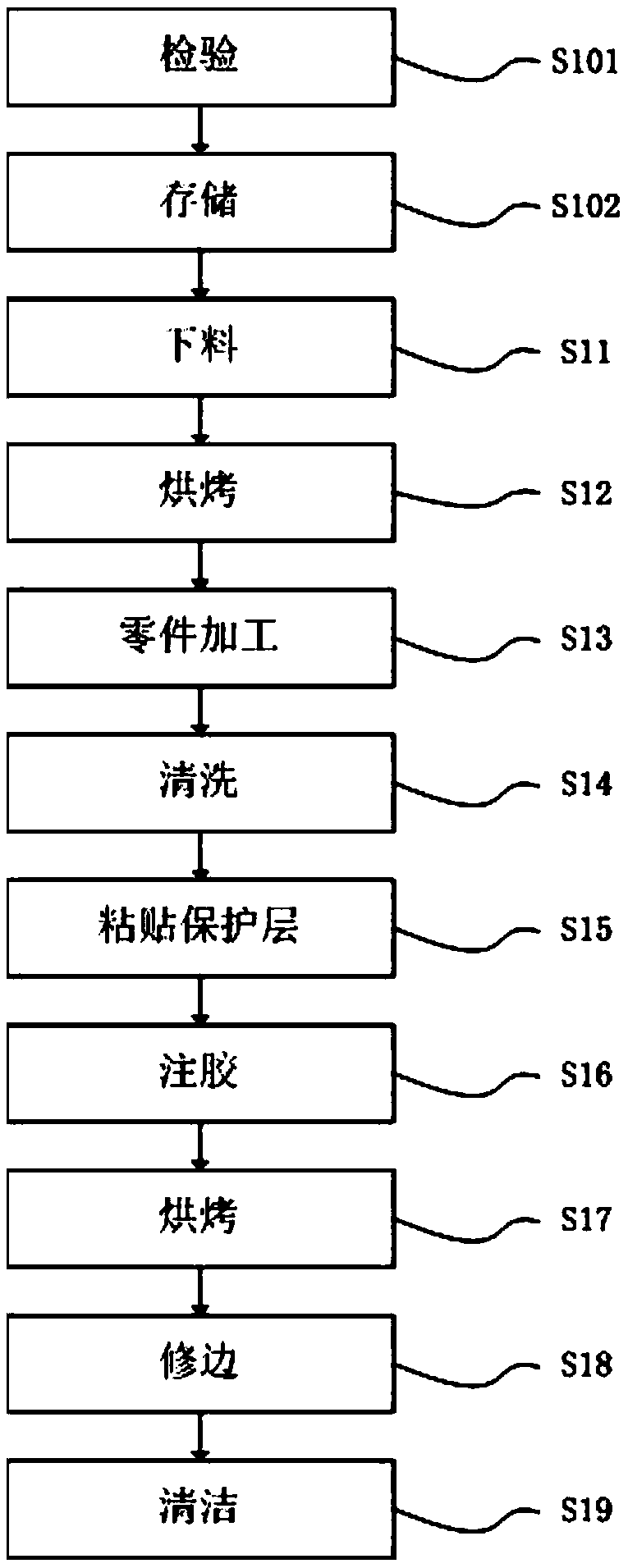

[0062] combine figure 1 , describe in detail the preferred embodiment of the production method of the water phantom of the present invention, as figure 1 As shown, it includes the following steps:

[0063] S11: blanking; according to the part size requirements in the drawing of the water model body, a margin of 1-2mm is given to cut out the part blank on the said production material;

[0064] S12: baking; baking the part blank;

[0065] S13: Parts processing; design tooling fixtures, formulate reasonable cutting amount, and select reasonable cutting fluid and cutting parameters according to material characterist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com