Adjusting method for increasing pressure of liquid phase outlet of disc separator

A disc separator and liquid phase outlet technology, which is applied in the field of disc separators, can solve the problems such as the adjustment range cannot meet the requirements, leakage, etc., achieve the effect of automatic compensation for pressure resistance and wear resistance, and avoid leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

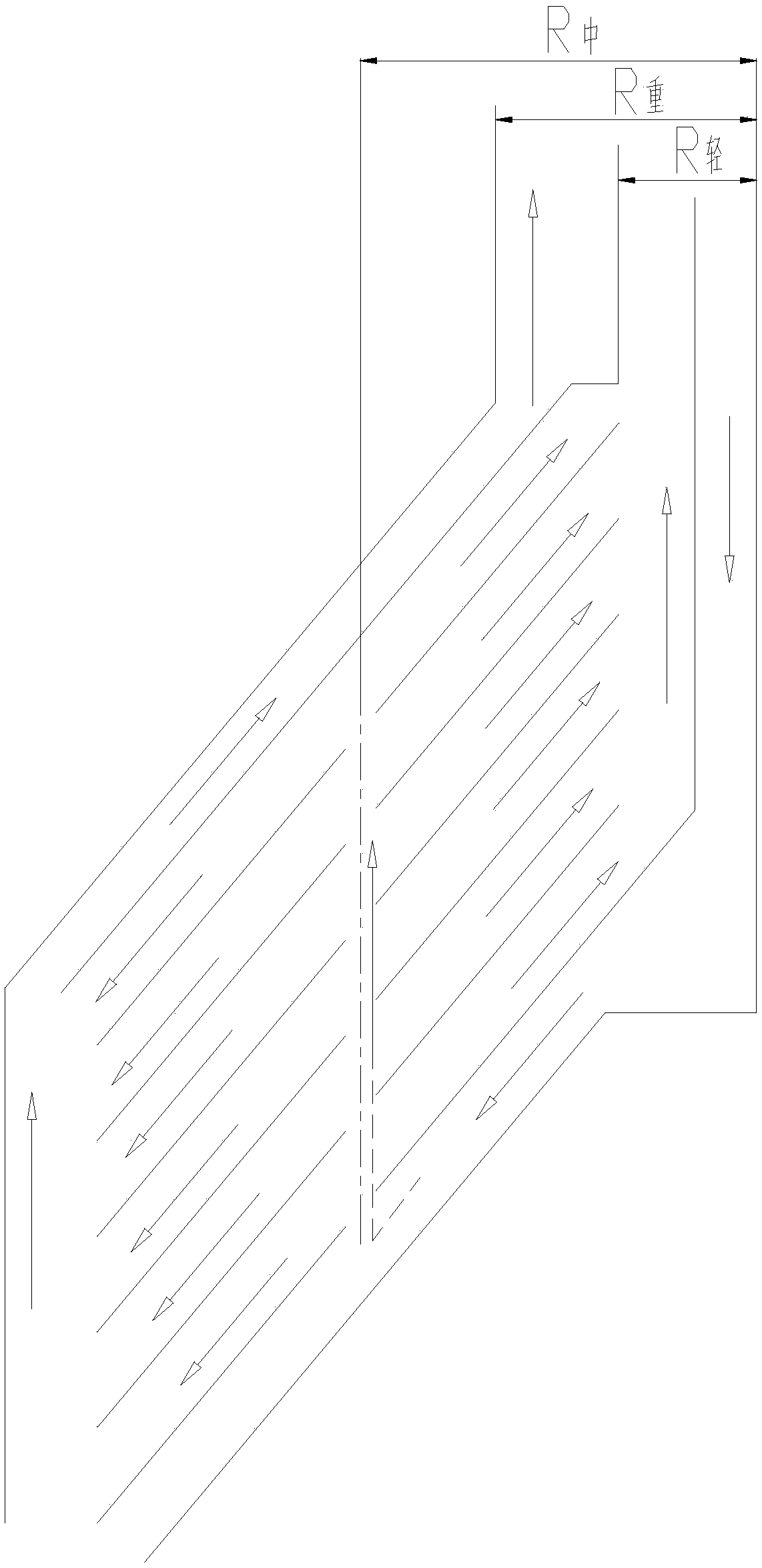

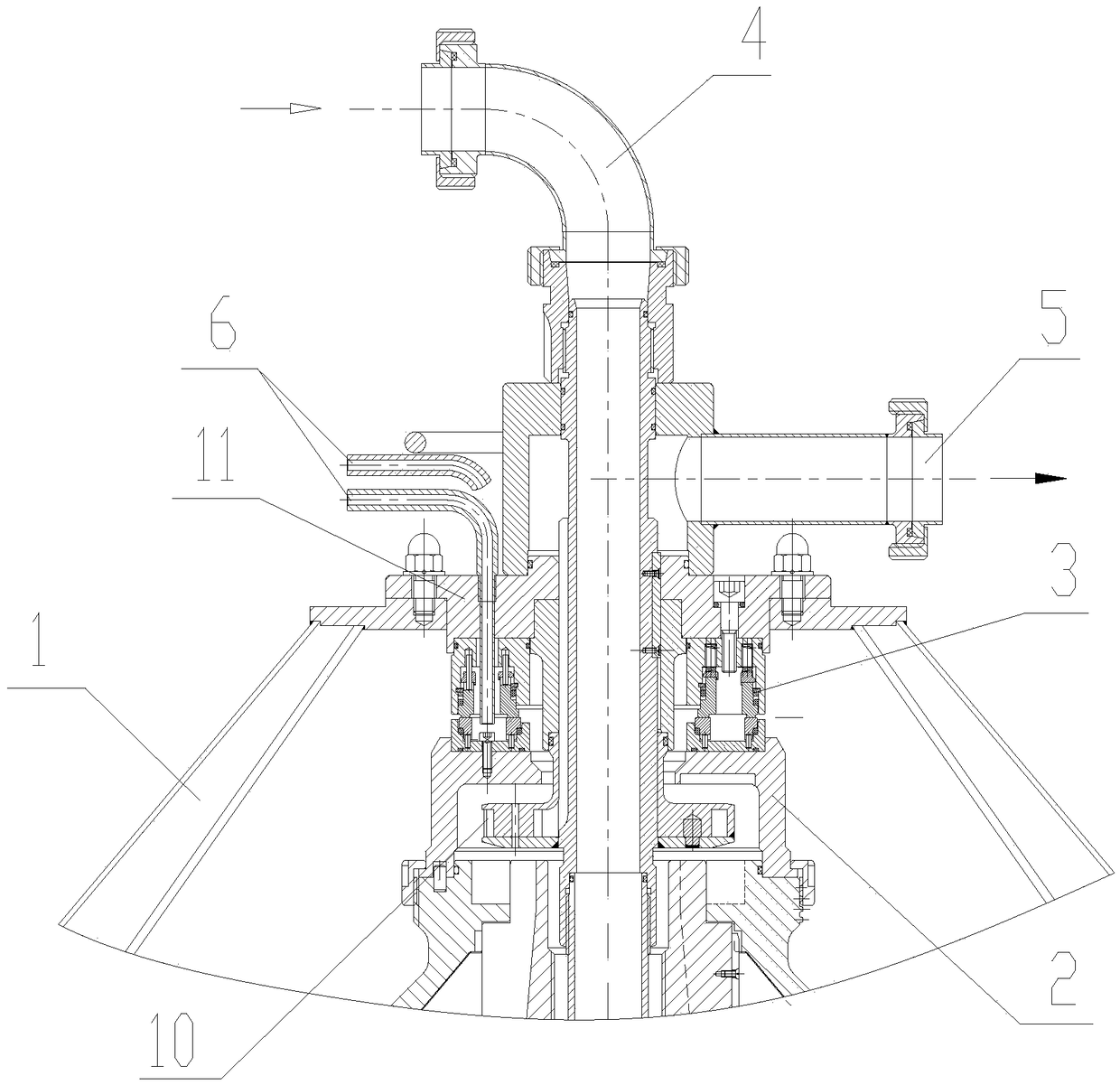

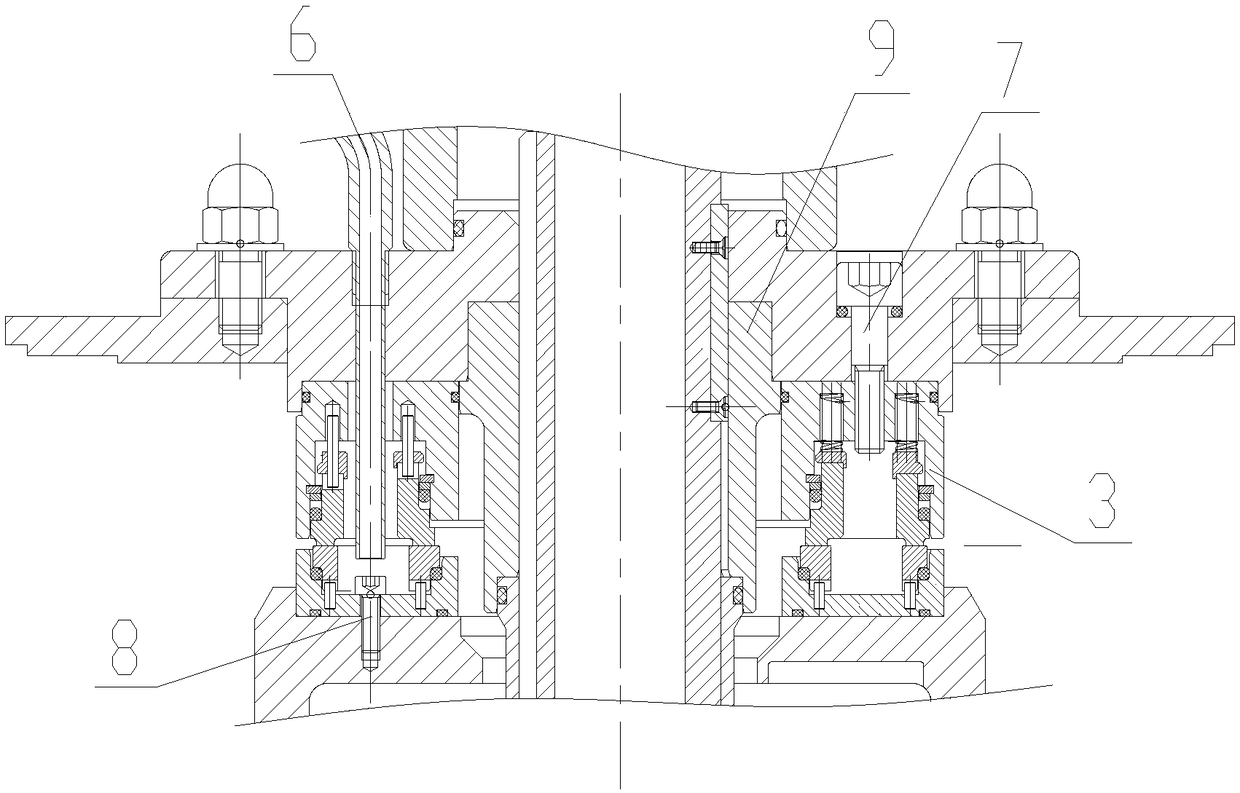

[0030] see figure 2 , image 3 In this embodiment, an adjustment method for increasing the outlet pressure of the liquid phase of a disc separator is to install a radially distributed double end seal in the liquid phase back pressure formation area toward the discharge direction, and a centripetal pump is provided in the back pressure formation area 10. When the pressure in the back pressure formation area changes, the double end seals keep the output end of the centripetal pump 10 completely isolated from the inner space of the housing 1, and the multiple end seals are equipped with a water cooling system.

[0031] Specifically, the multiple end face seals are realized by setting the radial double end face sealing device 3, the radial double end face sealing device 3 includes the upper seat 301 fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com