A method for reducing nitrogen addition in molten steel during continuous casting

A technology for increasing the amount of nitrogen and molten steel, which is used in foundry equipment, casting melt containers, manufacturing tools, etc., and can solve the problems of increasing oxygen, easily increasing nitrogen in molten steel, and easily generating cracks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

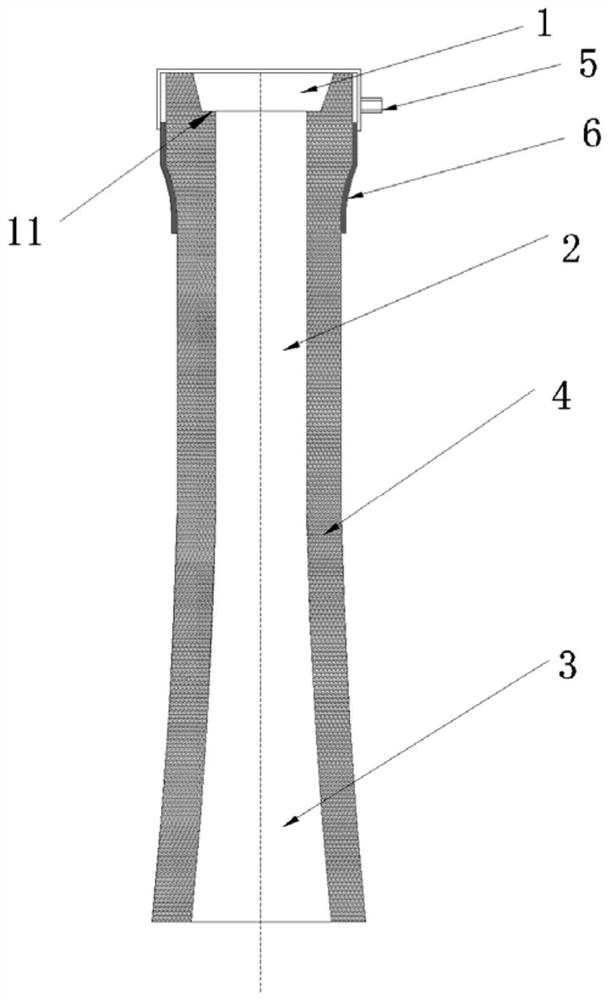

[0072] The invention provides a method for reducing nitrogen increase in the continuous casting process. This method mainly includes the following four aspects:

[0073] 1. Compared with the prior art of argon gas plus single-layer gasket sealing, the outstanding feature of the present invention is: the present invention maintains the argon gas seal and the single-layer gasket seal, and in the gasket Another two-layer sealing structure is installed, and a three-layer sealing structure is adopted at the junction of the long nozzle of the ladle and the lower nozzle of the ladle. The outermost layer of the sealing structure is the traditional first gasket layer, the middle layer is the second gasket layer, and the innermost layer is the cement gasket layer.

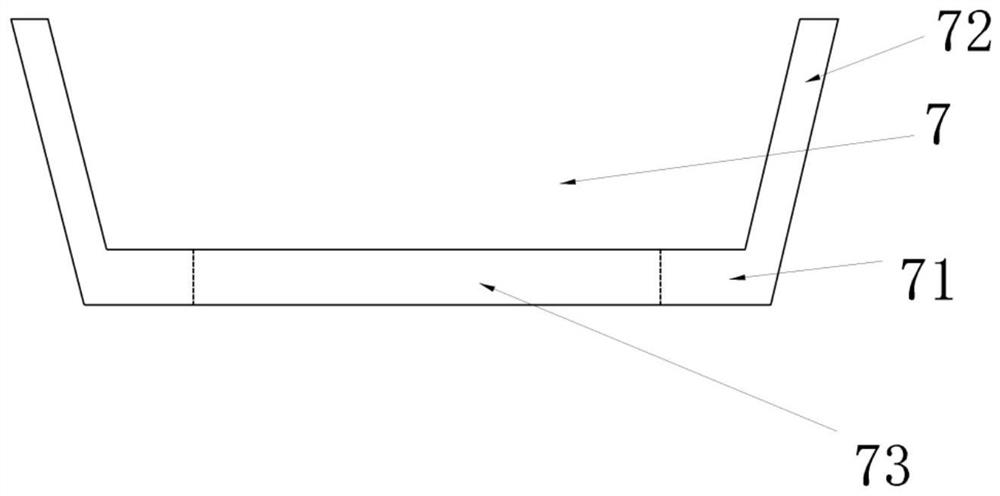

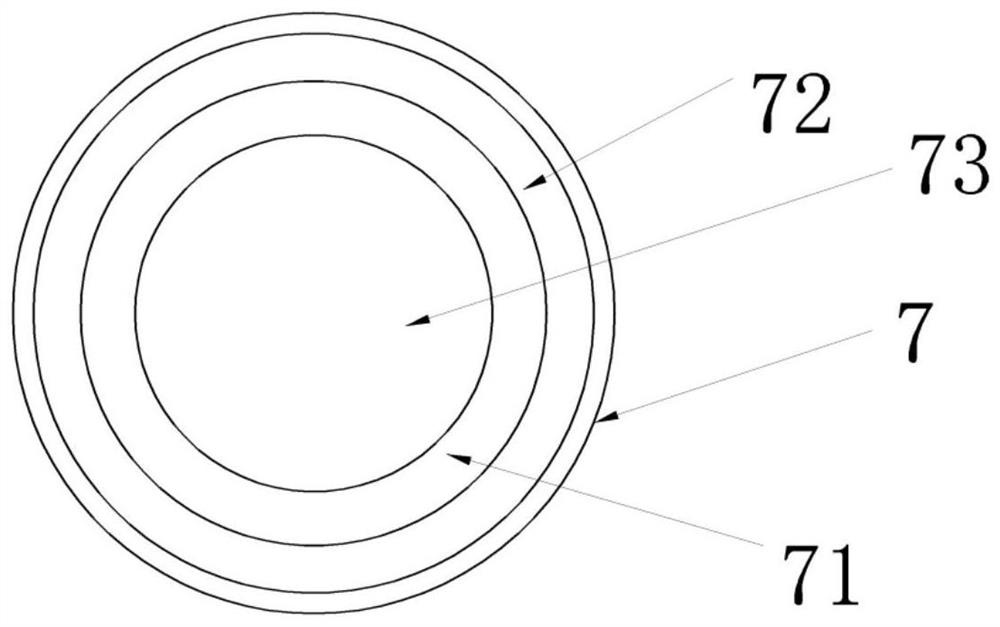

[0074] Both the first gasket layer and the second gasket layer are made of aluminum silicate fiber. The bottom 71 of the first gasket 7 is in the shape of a hollow ring. The annular platform 11 is the same, the bottom 71 o...

Embodiment 2

[0093] The invention provides a method for reducing nitrogen increase in the continuous casting process. This method mainly includes the following four aspects:

[0094] 1. Compared with the prior art of argon gas plus single-layer gasket sealing, the outstanding feature of the present invention is: the present invention maintains the argon gas seal and the single-layer gasket seal, and in the gasket Another two-layer sealing structure is installed, and a three-layer sealing structure is adopted at the junction of the long nozzle of the ladle and the lower nozzle of the ladle. The outermost layer of the sealing structure is the traditional first gasket layer, the middle layer is the second gasket layer, and the innermost layer is the cement gasket layer.

[0095] Both the first gasket layer and the second gasket layer are made of aluminum silicate fiber. The bottom 71 of the first gasket 7 is a hollow ring shape, and the shape and size of the bottom 71 on the horizontal secti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com