Assembly-type cone-column-plate-column-combined foundation for electric transmission line and construction method thereof

A technology of transmission lines and composite foundations, which is applied in the direction of basic structure engineering and construction, can solve the problems of large volume of solid concrete main columns and difficult transportation, etc., and achieves benefits for construction operations and environmental protection, obvious economic benefits, and convenient transportation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

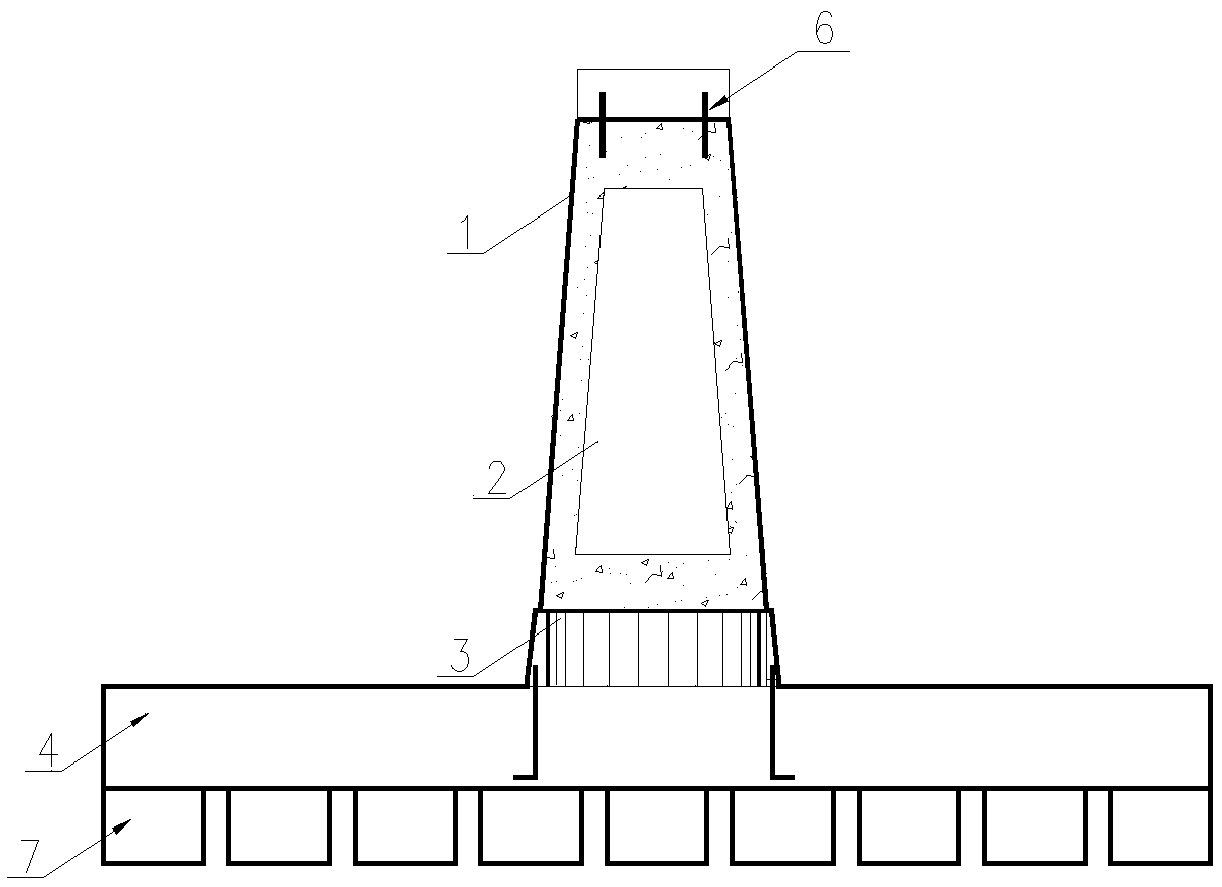

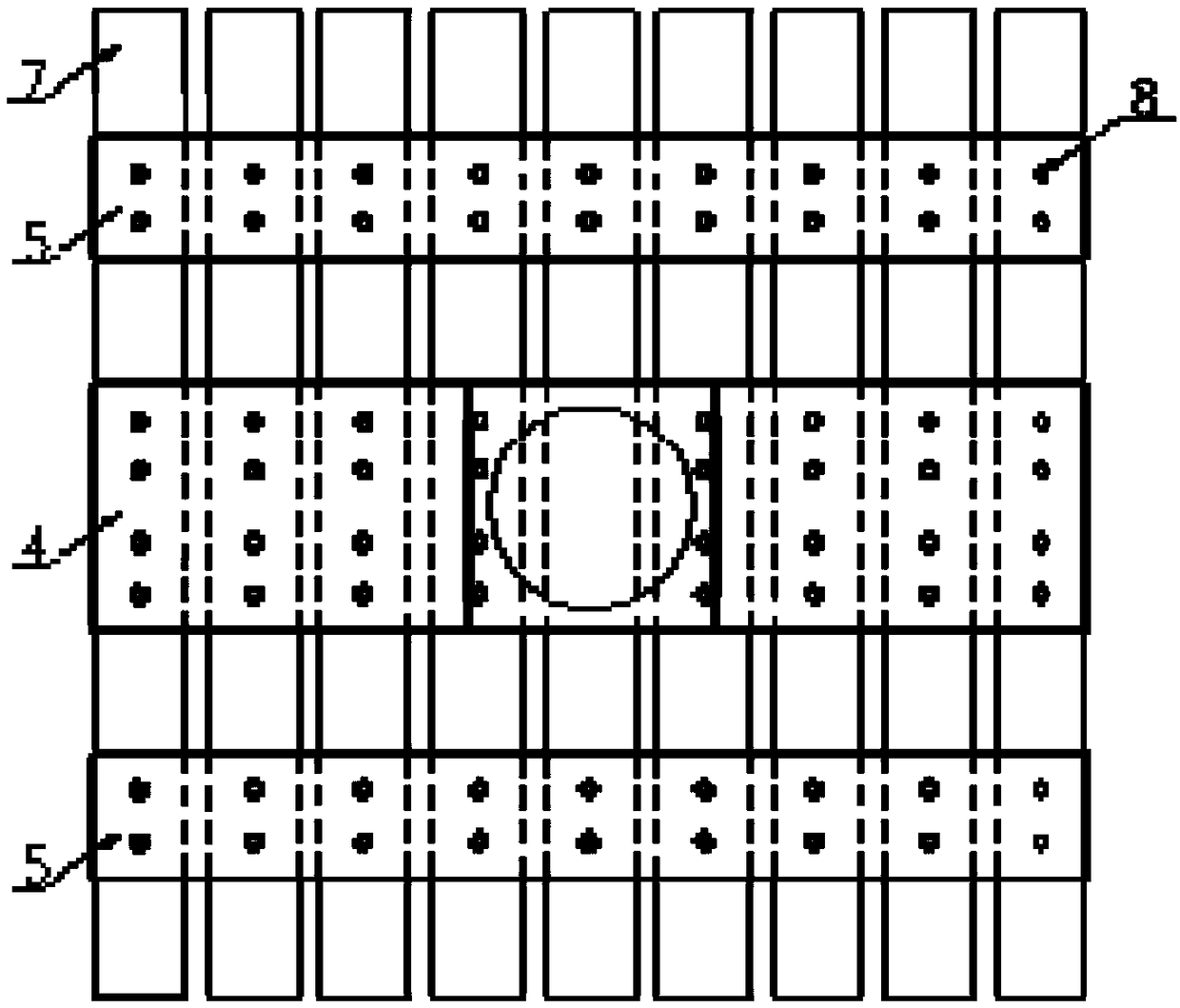

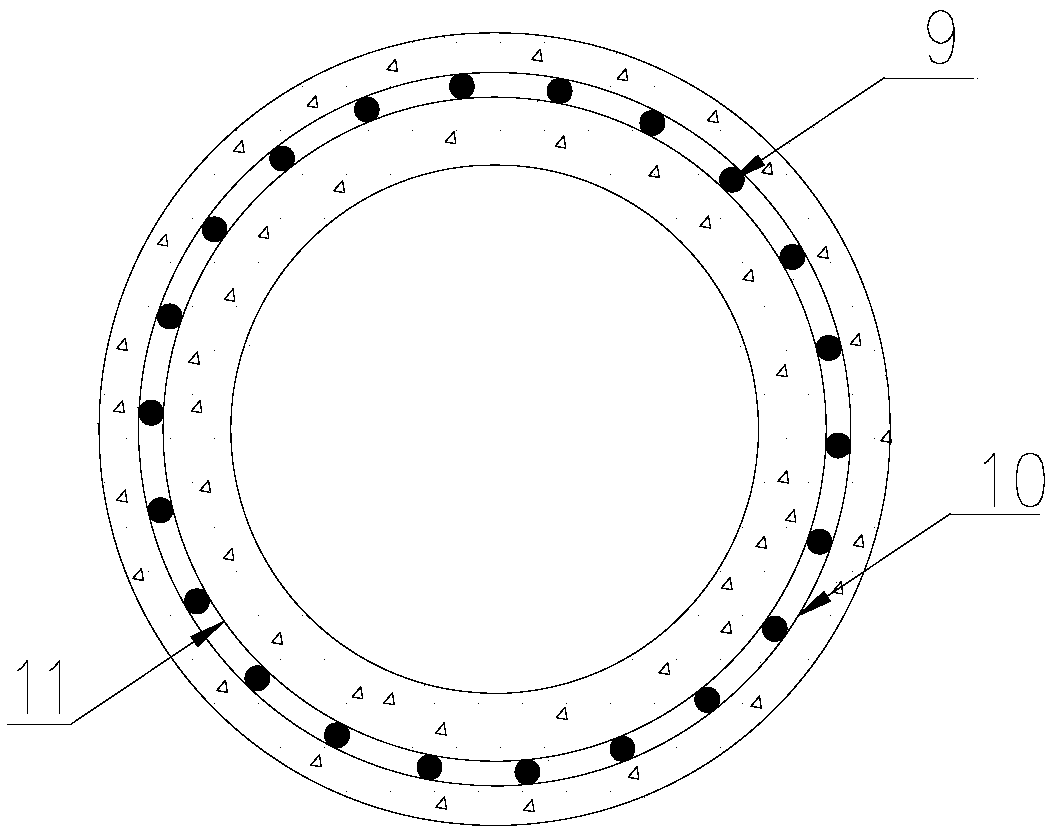

[0035] see figure 1 , the present invention is an assembled cone-column-slab-column composite foundation for power transmission lines, which is a main concrete structure, including a base and a support section connected to the base; the support section includes cone columns arranged in sequence from top to bottom Section 1 and hollow section 2, the top of the cone column section 1 is connected to the embedded part 6, and the base includes a central concrete beam 4 connected to the support section through a flange 3, and the two sides of the long side of the central concrete beam 4 are parallel An external concrete beam 5 is provided, and the middle concrete beam 4 and the external concrete beam 5 are fixed together by a plurality of concrete slats 7 arranged in parallel. The circular space inside the concrete structure is provided with a reinforcement cage, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com