Fabricated steel frame outer wall system and construction method thereof

A steel frame, prefabricated technology, applied in the direction of walls, floors, building components, etc., can solve the problems of low overall strength of the external wall system, many wet installations on the external wall, and a large number of plate components, so as to achieve firm and reliable connection nodes. , saving labor cost, high standardization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

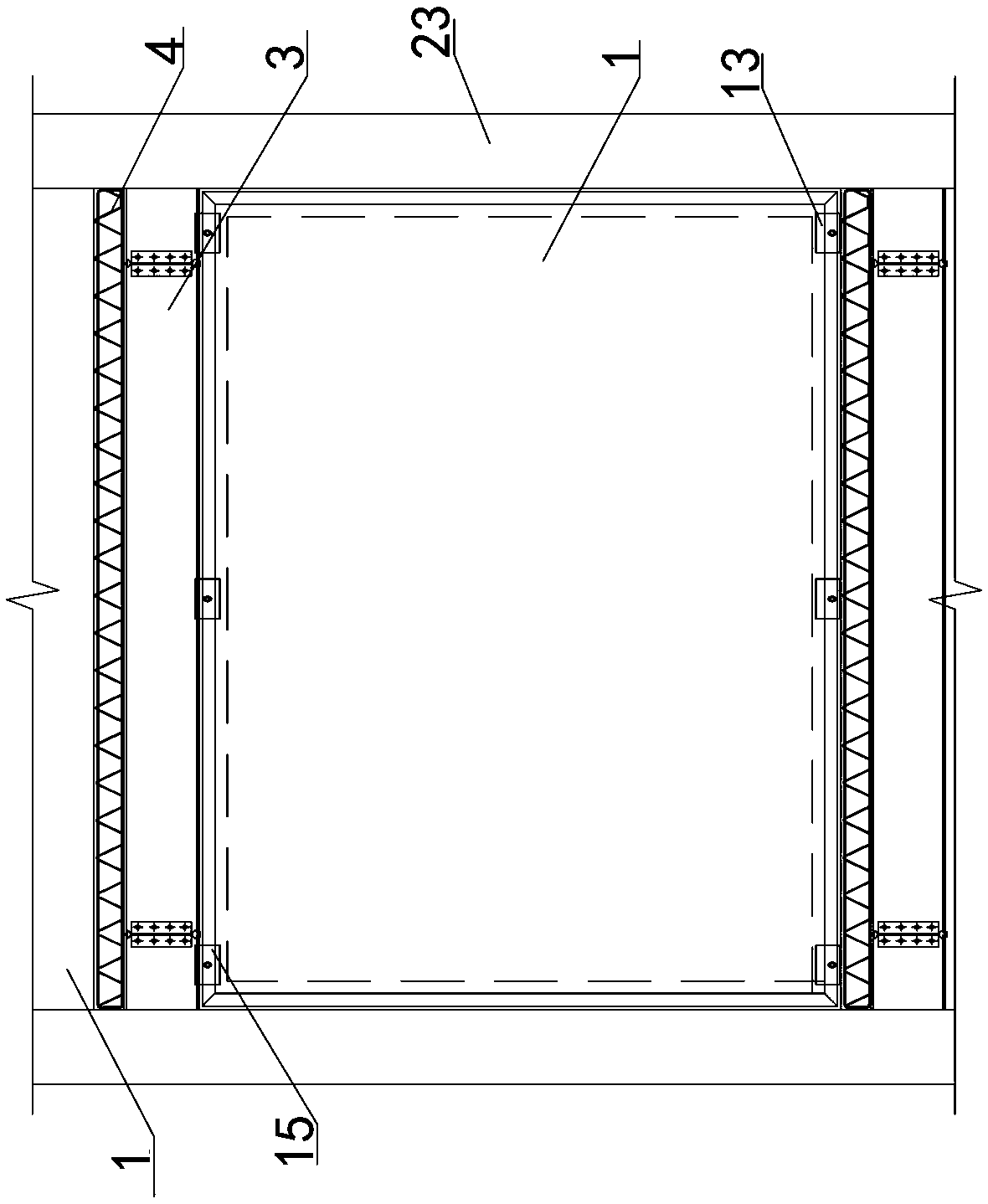

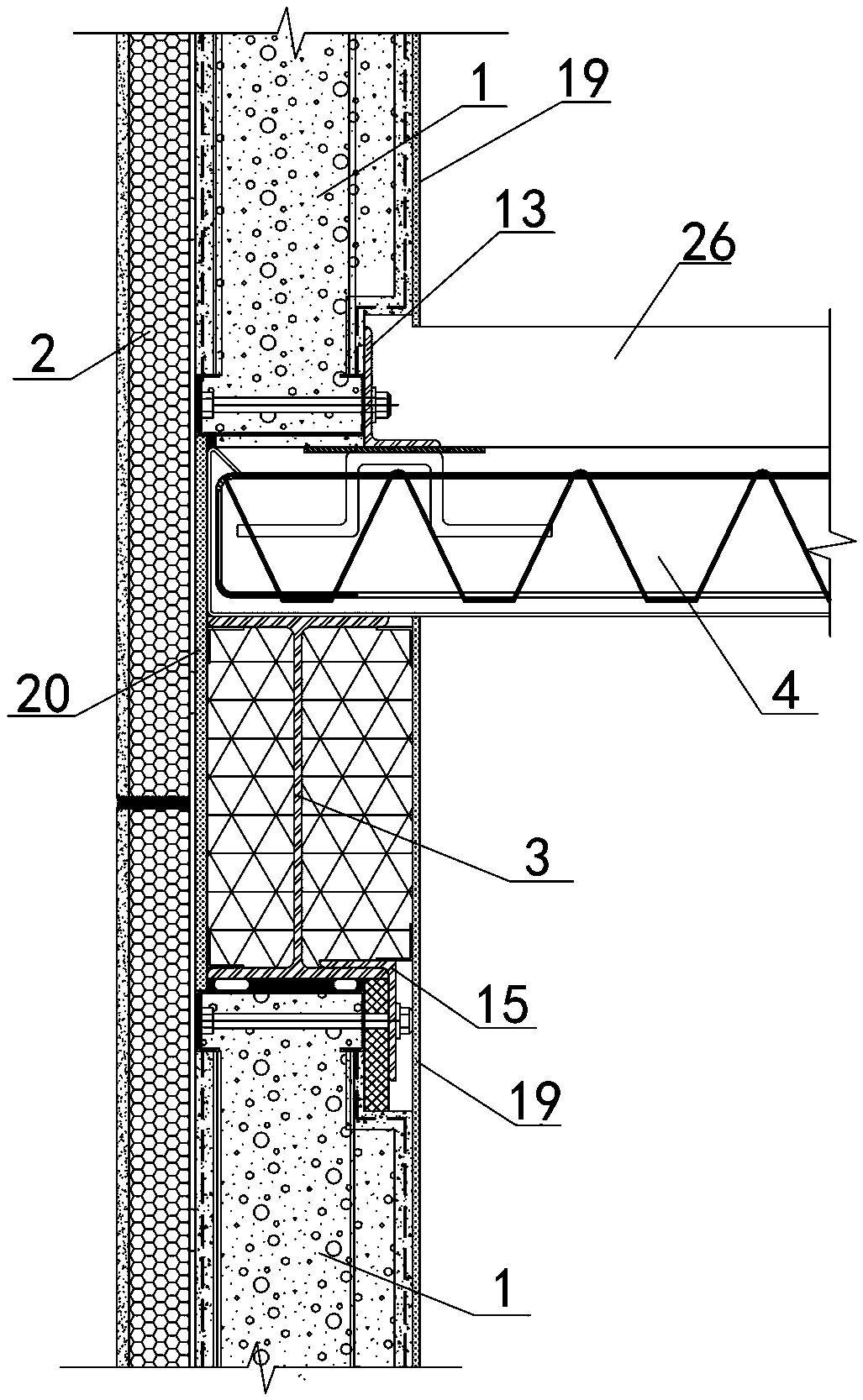

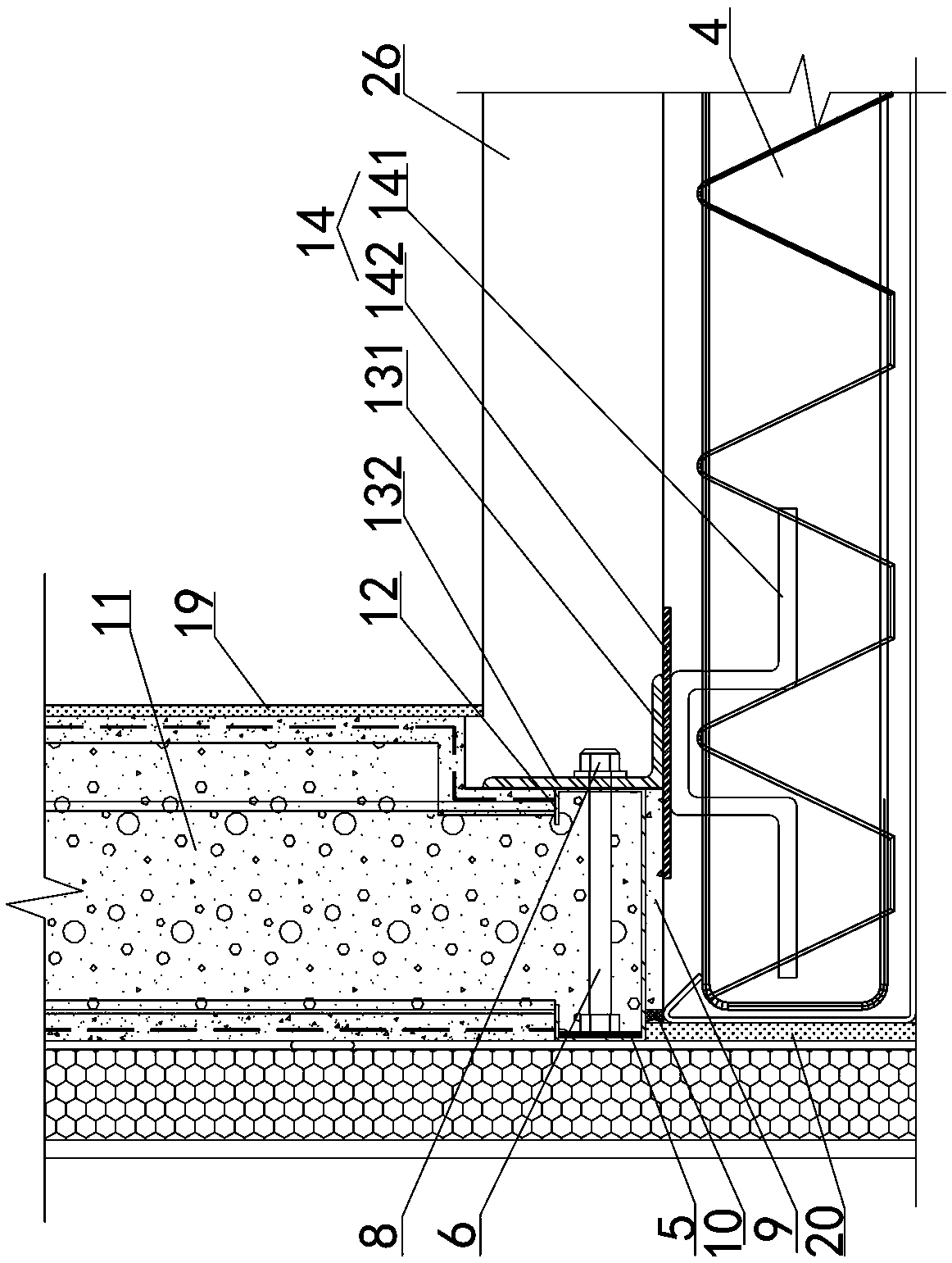

[0048] Examples see figure 1 As shown, a prefabricated steel frame exterior wall system includes a steel frame exterior wall panel 1 and an externally hung thermal insulation and decorative integrated panel 2, and also includes a horizontal structure enclosed and fixed on the upper and lower sides of the steel frame exterior wall panel. The horizontal structure includes steel beams 3 on the lower side and steel truss floor slabs 4 on the upper side, see Figure 2-3 As shown, the steel frame exterior wall panel includes a core material 11 and a frame frame 12 . In this embodiment, the skin of the board is 20 mm thick and dense foamed cement, and the core material is low-density foamed cement mixed with polystyrene particles.

[0049] see figure 2 As shown, the upper side of the steel frame exterior wall panel is connected to the steel beam through the upper connection structure, the lower side of the steel frame exterior wall panel is connected to the steel truss floor plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com