Double-flow tubular electric heater provided with insulating guide sleeve insulating material for scale inhibition of heat exchange surface

A technology of guiding sleeve and insulating material, applied in the direction of fluid heater, water heater, heating element shape, etc., can solve the problems of shortened service life, large volume, strength, safe installation space, inconvenient construction cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

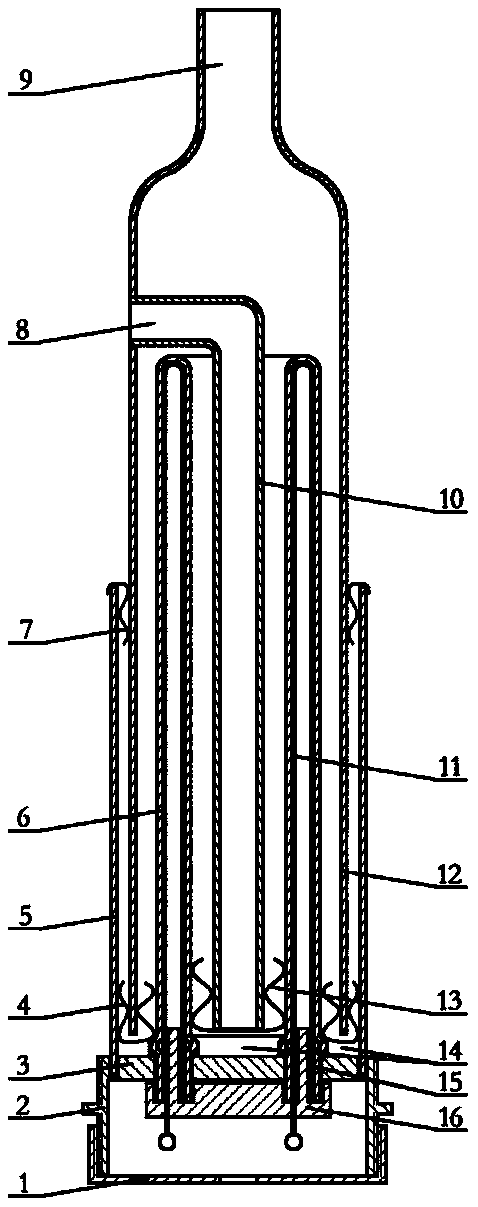

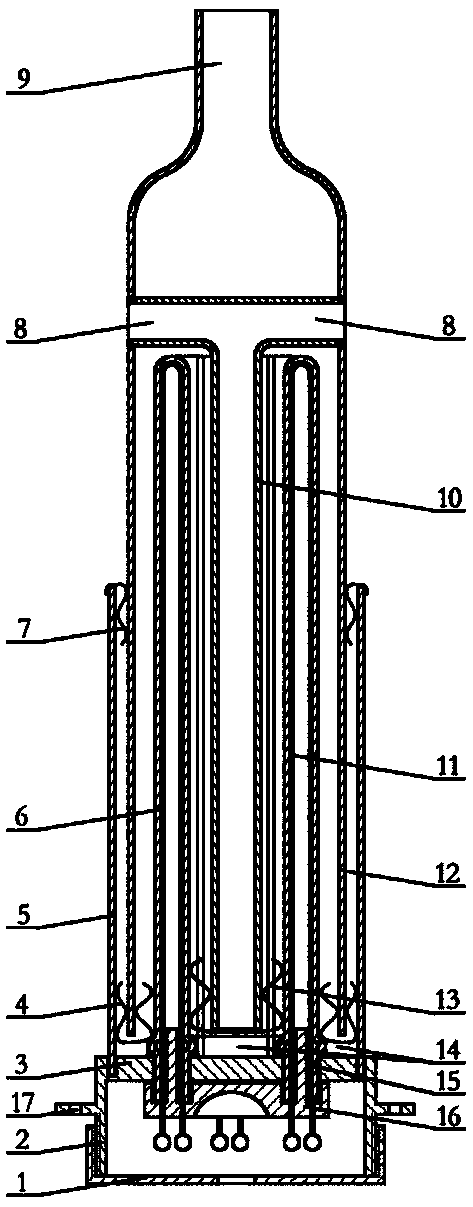

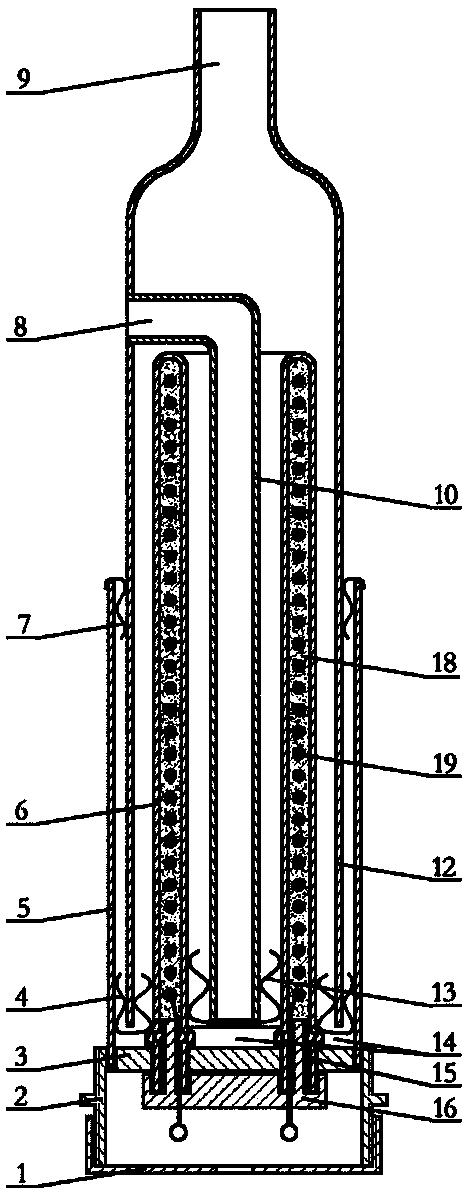

[0107] figure 1 It is the first embodiment of the present invention, the heater is the ring cavity tube skeleton 6, the electric heating film is a semiconductor electric heating film layer 11, a single heating unit, and the inner core electric insulation guide tube 10 is inverted L-shaped, and the electric heater is in the Schematic diagram of the front section structure of the thermoelectric heater installed at the bottom of the water tank.

[0108] Equipped with insulating diversion sleeve, insulating material, heat exchange surface, anti-scaling, double-channel tubular electric heater, including protective end cover 1, connecting flange 2, electrical insulation fixing base 3, electric heater skeleton 6, conductor electric heating film layer 11. Connect the electrode wire 15 and the electrical insulation rubber sleeve 16 to form a cylindrical electric heater. It consists of outer insulating diversion sleeve 5, intermediate positioning connection support 4, annular water inl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com