Sterilization method of fruit and vegetable juice

A fruit and vegetable juice, fruit and vegetable technology, applied in food science and other directions, can solve the problems of non-enzymatic browning, deterioration of fruit and vegetable juice quality, and precipitation, and achieve the effect of killing pathogenic bacteria and good sterilization effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Choose ripe fresh red-fleshed dragon fruit as raw material, carry out pretreatment; Get dragon fruit fruit block 1cm after peeling and cutting 3 ;Press the obtained dragon fruit pieces at low temperature (0-8°C) to obtain pulp; the pulp is further coarsely filtered to remove seeds and a small amount of large pulp to obtain raw juice; the obtained raw juice is placed in a vacuum environment of 0.01MPa and degassed for 10min , to obtain degassed pitaya fruit juice;

[0025] Sterilization treatment: The obtained degassed pitaya juice is subjected to high-pressure homogenization treatment: 150MPa, homogenization once (within 15 seconds), the feed temperature is 30°C, and immediately cooled to 4°C after homogenization, and the pulp particle size D is controlled. [4,3]≤20μm, D[3,2]≤20μm, D50≤8μm; heat-assisted ultrasonic sterilization treatment: treatment temperature is 52°C, 400W, treatment 5min.

[0026] The sample was taken out and cooled to 4°C; the cooled dragon fruit j...

Embodiment 2

[0030] Choose ripe fresh red-fleshed dragon fruit as raw material, carry out pretreatment; After the obtained dragon fruit is taken out, peel and cut, obtain dragon fruit fruit block 1cm 3 ;Press the obtained dragon fruit pieces at low temperature (0-8°C) to obtain pulp; the pulp is further coarsely filtered to remove seeds and a small amount of large pulp to obtain raw juice; the obtained raw juice is placed in a vacuum environment of 0.01MPa and degassed for 10min , to obtain degassed pitaya fruit juice;

[0031] Sterilization treatment: The obtained degassed pitaya juice is subjected to high-pressure homogenization treatment: 150MPa, homogenization 3 times, feed temperature 25°C, and cooling to 4°C immediately after homogenization;

[0032] Aseptically fill the cooled pitaya fruit juice in 350mL glass bottles, seal at 4°C and refrigerate in the dark.

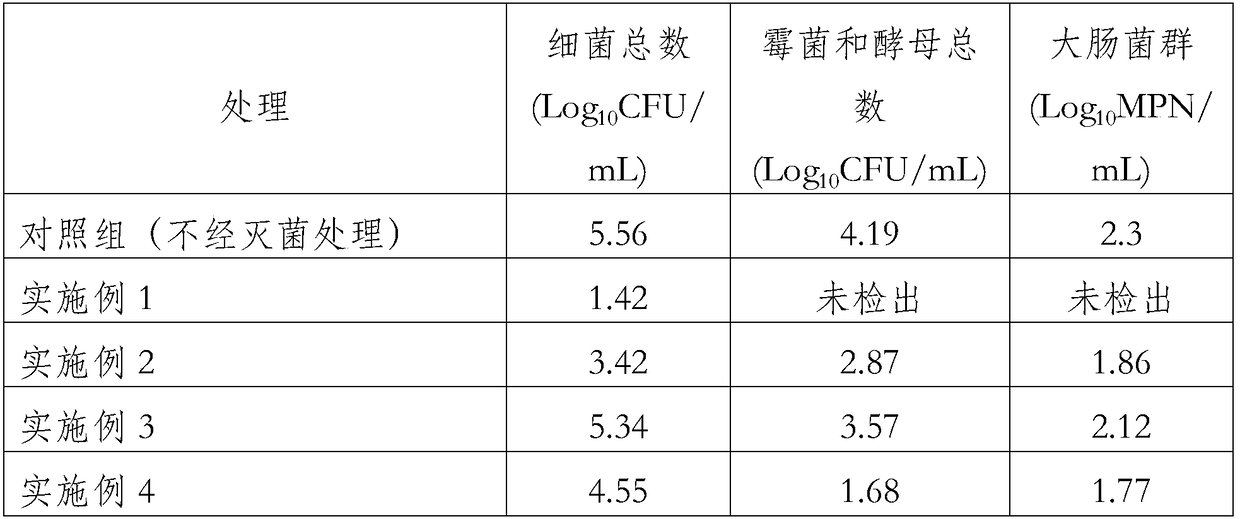

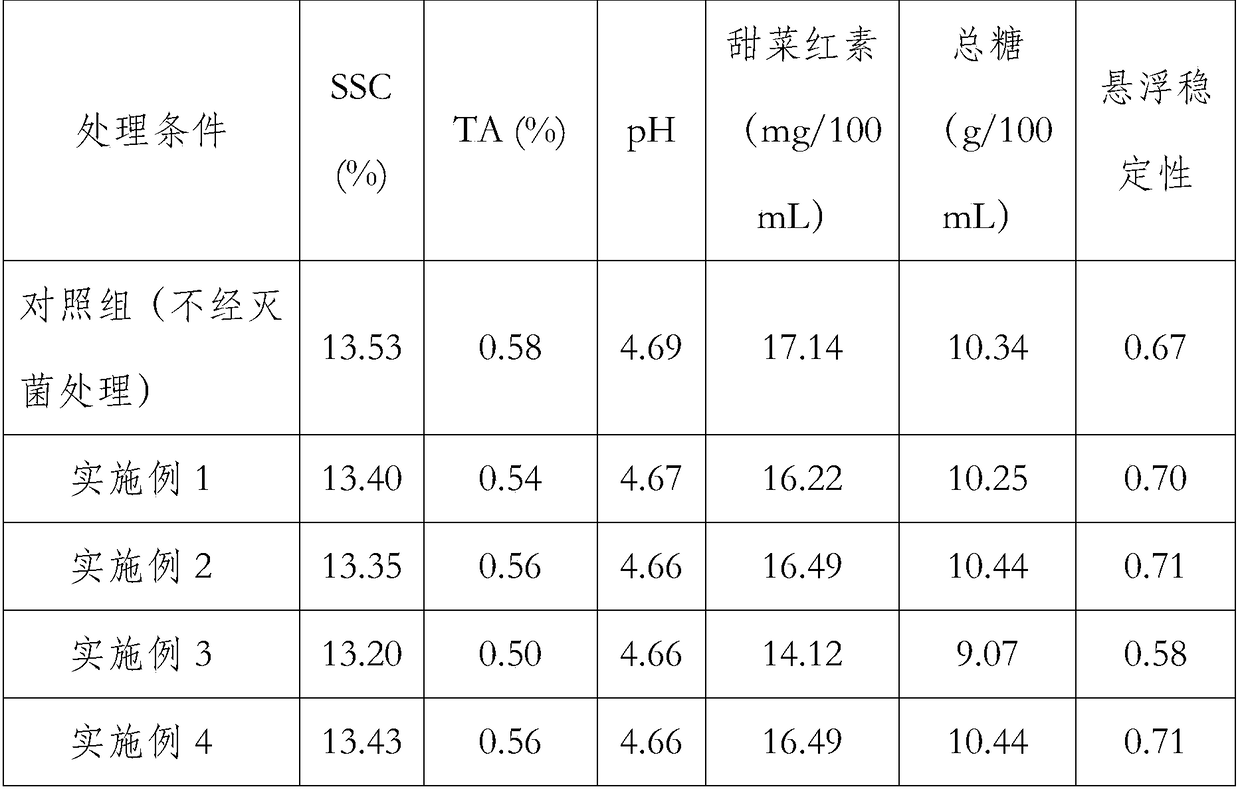

[0033] The treatment method of this embodiment is shown in Table 1 to the impact of the microbial index in the pitaya frui...

Embodiment 3

[0035] Choose ripe fresh red-fleshed dragon fruit as raw material, carry out pretreatment; After the obtained dragon fruit is taken out, peel and cut, obtain dragon fruit fruit block 1cm 3 ;Press the obtained dragon fruit pieces at low temperature (0-8°C) to obtain pulp; the pulp is further coarsely filtered to remove seeds and a small amount of large pulp to obtain raw juice; the obtained raw juice is placed in a vacuum environment of 0.01MPa and degassed for 10min , to obtain degassed pitaya fruit juice;

[0036] Sterilization treatment: adopt thermal sterilization treatment.

[0037] The treatment method of this embodiment is shown in Table 1 to the impact of the microbial index in the pitaya fruit juice, and is shown in Table 2 to the impact of the physicochemical index in the pitaya fruit juice.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com