Vertical shaft impact crusher with multiple shaping functions

A vertical shaft impact and crusher technology, applied in grain processing and other directions, can solve the problems of unreasonable gradation, poor fluidity of finished machine-made sand, and high porosity, and achieves increased impact probability, improved rationality and fluidity, and increased Effect of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

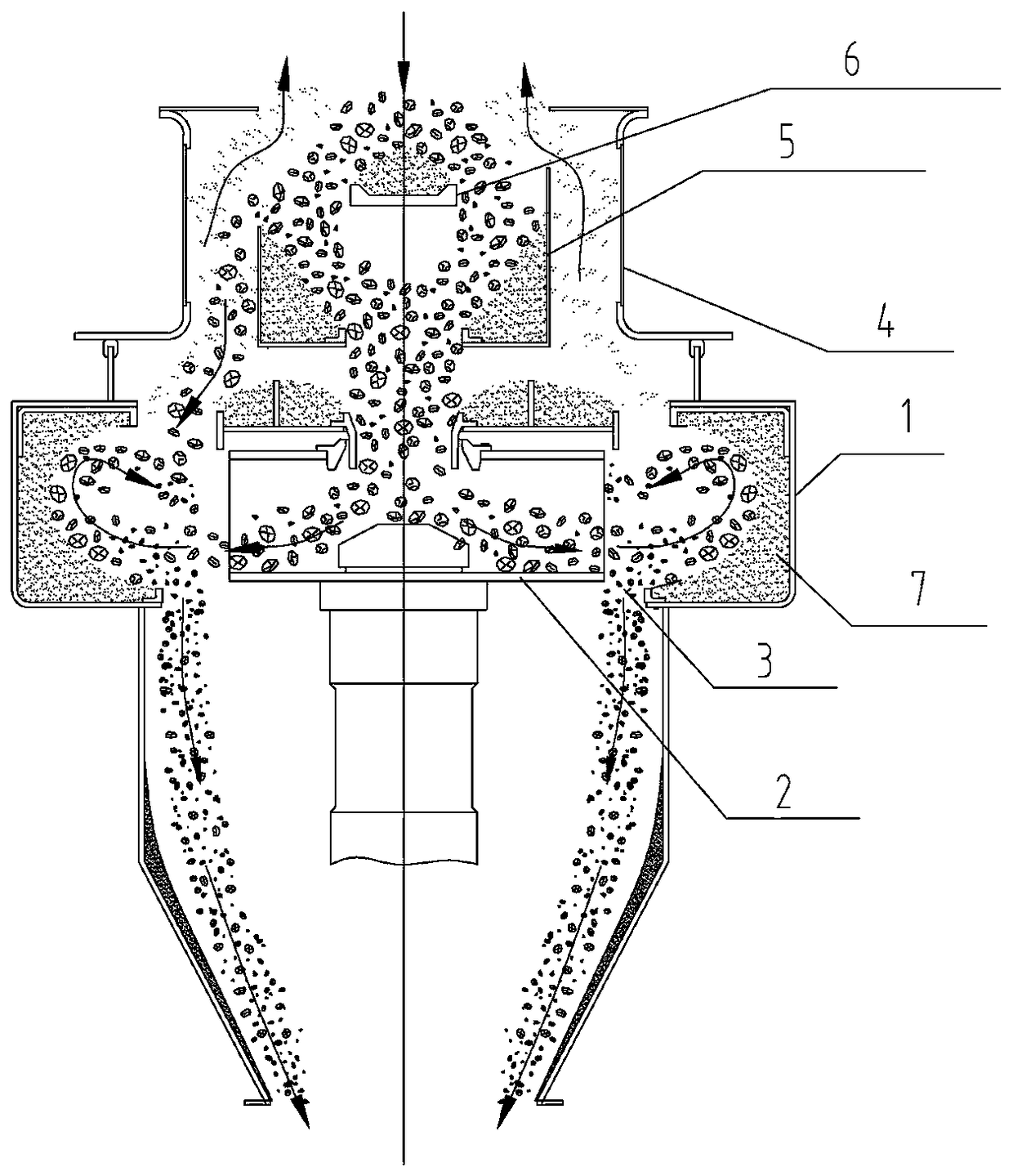

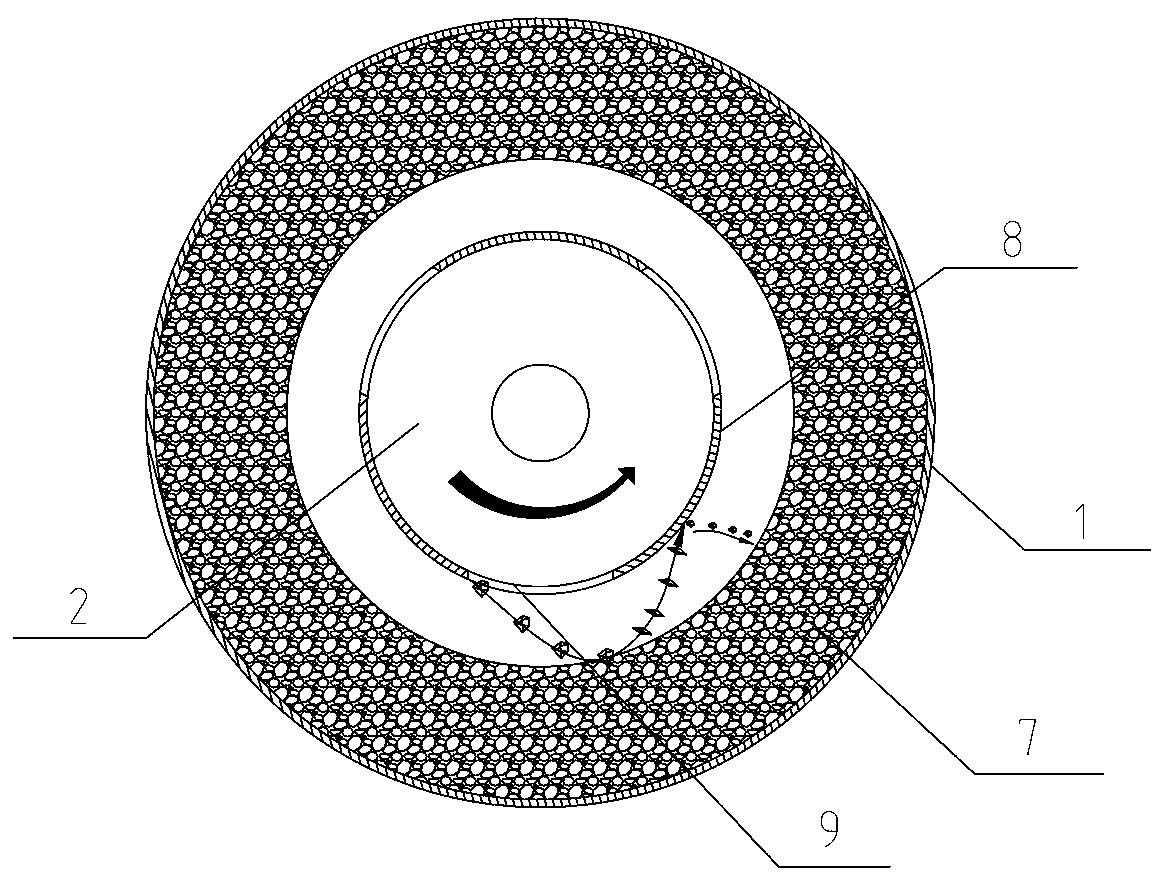

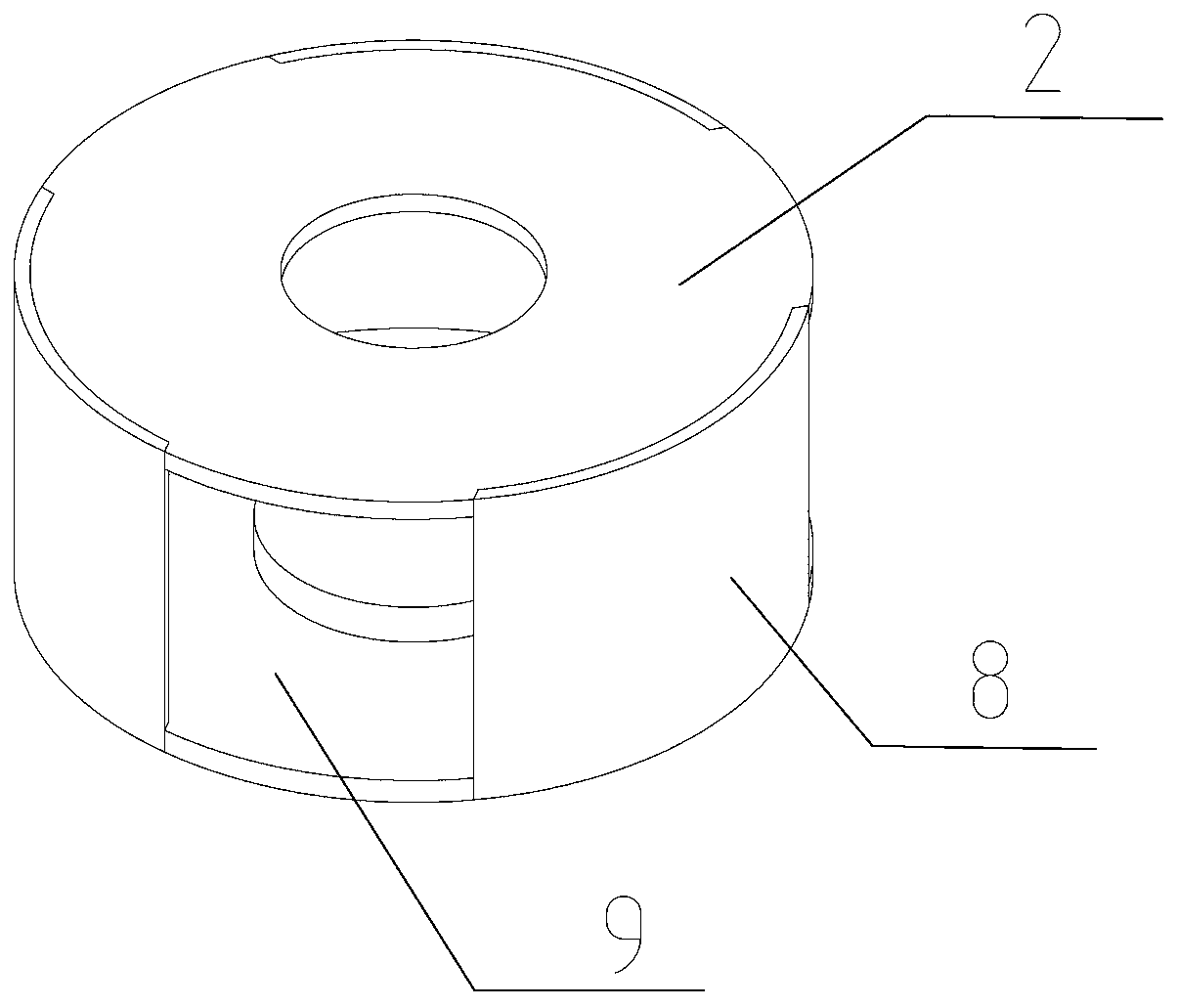

[0013] Such as Figures 1 to 3 As shown, a vertical shaft impact crusher with multiple shaping functions includes a crushing chamber 1 and a rotor 2. A crushing chamber is formed inside the crushing chamber 1. The rotor 2 is rotatably installed in the crushing chamber through a main shaft. There is a crushing chamber at the bottom of the crushing chamber. Outlet 3, the top of the crushing chamber 1 has a material distribution chamber 4, the inside of the material distribution chamber 4 is fixedly installed with a material distribution inner cylinder 5 through a rib plate, and the center of the opening of the material distribution inner cylinder 5 is equipped with a bulk material tray 6 through a bracket. The side wall of the described material distribution inner tube 5 is increased, the top of the side wall of the material distribution inner tube 5 is higher than the height of the top of the bulk material tray 6, and the top of the side wall of the material distribution inner t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com