Resistance element lead pin shear-formation device and method

A resistor and pin technology, applied in the field of resistor pin shearing and forming devices, can solve the problems of complex structure of pin shearing products, low cutting precision, and poor versatility, and achieve simple structure and strong versatility , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

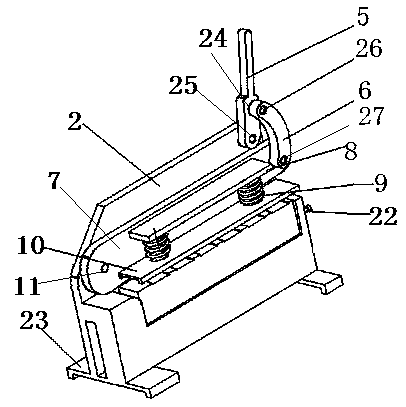

[0044] according to Figure 1-10 A kind of resistance pin shearing forming device described, comprises

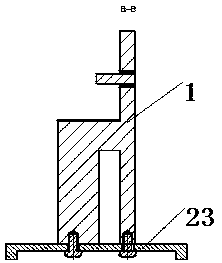

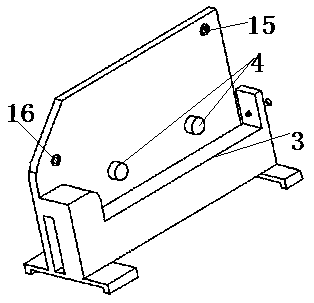

[0045] The mounting bracket 1 is composed of a wall plate 2 and a storage table 3. The wall plate 2 is arranged on the axial side of the storage table 3. The wall plate and the storage table are an integral structure. limit column 4;

[0046] A driving member is rotatably connected to one end of the wall plate 2;

[0047] A shearing mechanism, one end of the shearing mechanism is rotatably connected to the wall plate 2, and the other end of the shearing mechanism is rotatably connected to the driving member;

[0048] The clamping mechanism is connected to the upper surface of the storage table, and its rear side wall is in contact with the two limit posts 4. The upper surface of the clamping mechanism is higher than the lower edge of the shearing mechanism, and is used to clamp the resistance to be sheared;

[0049] A locking mechanism, the locking mechanism is connected...

Embodiment 2

[0053] according to figure 1 The above-mentioned resistance pin shearing and forming device is different from the first embodiment in that: the driving member includes a handle 5 and a connecting rod 6; the lower part of the handle 5 has a sixth through hole 24 from top to bottom and the seventh through hole 25, the eighth through hole 26 and the ninth through hole 27 are respectively opened at the two ends of the connecting rod 6; the handle 5 and the connecting rod 6 are rotationally connected through the sixth through hole 24 and the eighth through hole 26; the handle 5 is rotatably connected to one end of the wall plate 2 through the seventh through hole 25, and the connecting rod 6 is rotatably connected to the shearing mechanism through the ninth through hole 27.

[0054] When starting pin cutting, a rotational torque is applied to the handle 5, and the torque is transmitted to the shearing mechanism through the connecting rod 6, and the resistance pin is sheared. The d...

Embodiment 3

[0056] according to figure 1 , Figure 4 , Figure 5 , Figure 7 and Figure 8 The above-mentioned resistance pin shearing and forming device is different from the first embodiment in that: the shearing mechanism includes a knife holder 7 and a pressing mechanism; two ends of the knife holder 7 are respectively provided with a second A through hole 11 and a second through hole 28, the bottom of the tool holder 7 has a cutting edge, the cutting edge is a semicircle with a bell mouth, and the upper edge of the cutting edge is lower than the upper surface of the clamping mechanism; One end of the knife rest 7 is rotatably connected with the middle part of the other end of the wall plate 2 through the first through hole 11, and the other end of the knife rest 7 is rotatably connected with the shearing mechanism through the second through hole 28; It matches with the clamping mechanism; the pressing mechanism is fixedly connected to the outer surface of the tool holder 7, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com