A sheet metal cutting machine that is convenient for adjusting the direction of workpieces

A technology for adjusting direction and sheet metal, applied in metal processing equipment, accessories of shearing machines, shearing devices, etc., can solve problems such as adjusting cutting direction, and achieve the effect of prolonging service life, reducing labor intensity, and convenient and quick operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

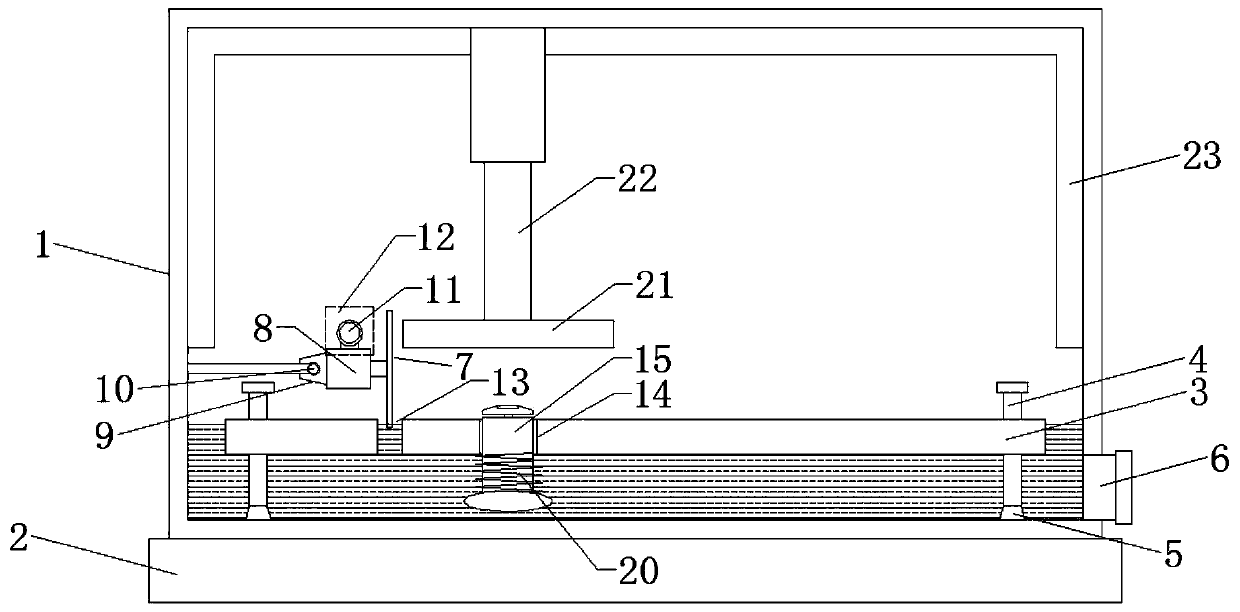

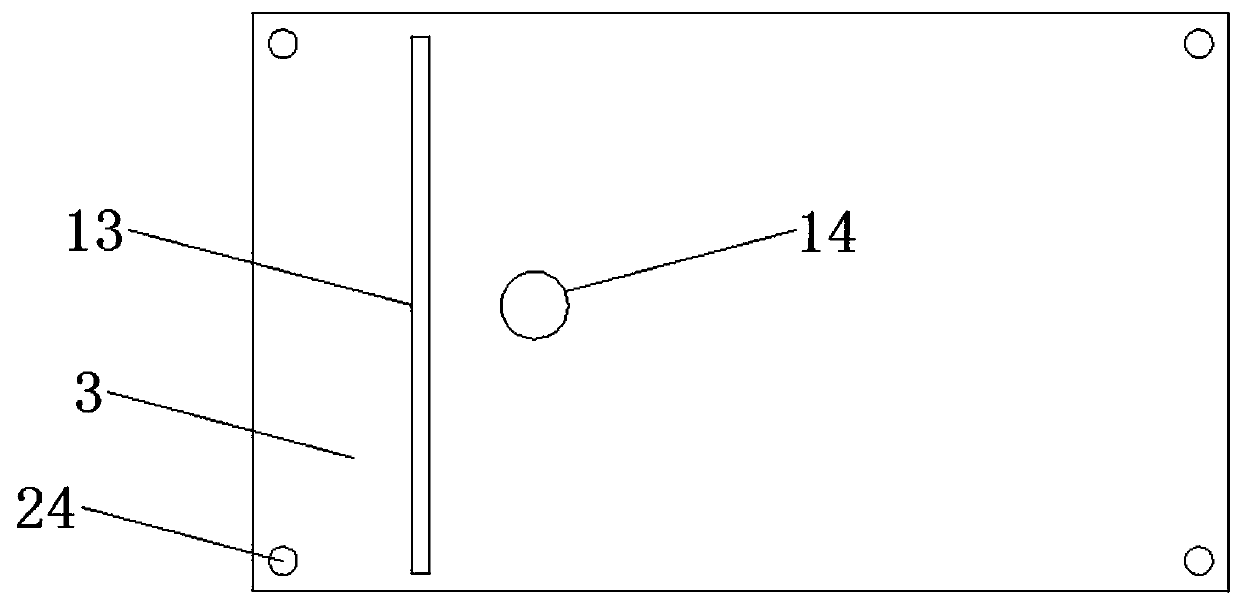

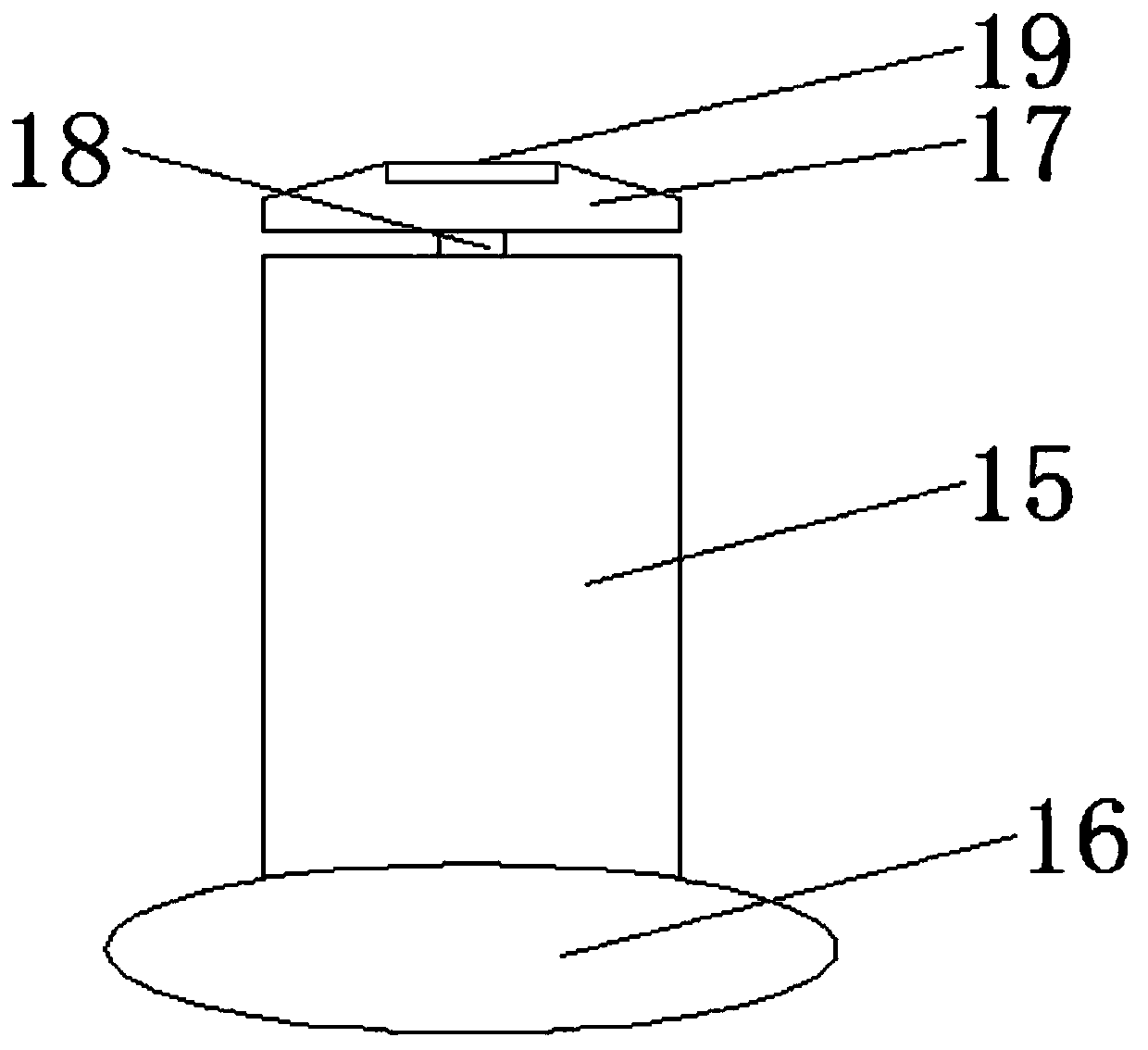

[0020] Please refer to the figure, in the embodiment of the present invention, a kind of sheet metal cutting machine that is convenient for adjusting the direction of the workpiece includes a box body 1, a base 2, a cutting table 3, a cutting knife 7 and a cutting motor 8; the box body 1 is fixed on the base 2, the cutting table 3 is horizontally located in the box body 1, and the four corners of the cutting table 3 are provided with threaded holes 24, and the internal threads of the threaded holes 24 are equipped with vertical support studs 4, and the support studs 4 can be adjusted as required, so that Change the height of cutting table 3, the lower end of supporting stud 4 fixes supporting foot 5, and the material of supporting foot 5 is rubber, plays the effect of supporting shock-absorbing noise reduction; Cutting knife 7 is vertically arranged on the top of cutting table 3, and cutting knife The central axis of 7 is fixedly connected on the output shaft of cutting motor 8...

Embodiment 2

[0027] A horizontal pressure plate 21 is arranged above the jacking mechanism, and the pressure plate 21 is fixed on the lower end of the hydraulic mechanism 22, and the hydraulic mechanism 22 is fixed on the top of the box body 1. The hydraulic mechanism 22 is mainly composed of a hydraulic cylinder, an oil pump, an oil tank, and a control switch. , the hydraulic mechanism 22 drives the pressing plate 21 to press down on the metal sheet below, press the metal sheet on the cutting table 3, and keep it fixed during cutting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com