Workpiece for welding threaded fastener and positioning through light beam and manufacturing method of workpiece

A threaded fastener and beam positioning technology, applied in welding accessories, welding equipment, welding equipment, etc., can solve the problems of high cost and complicated manufacturing process of riveting nuts, and achieve low welding pressure, good welding quality and high welding efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 12

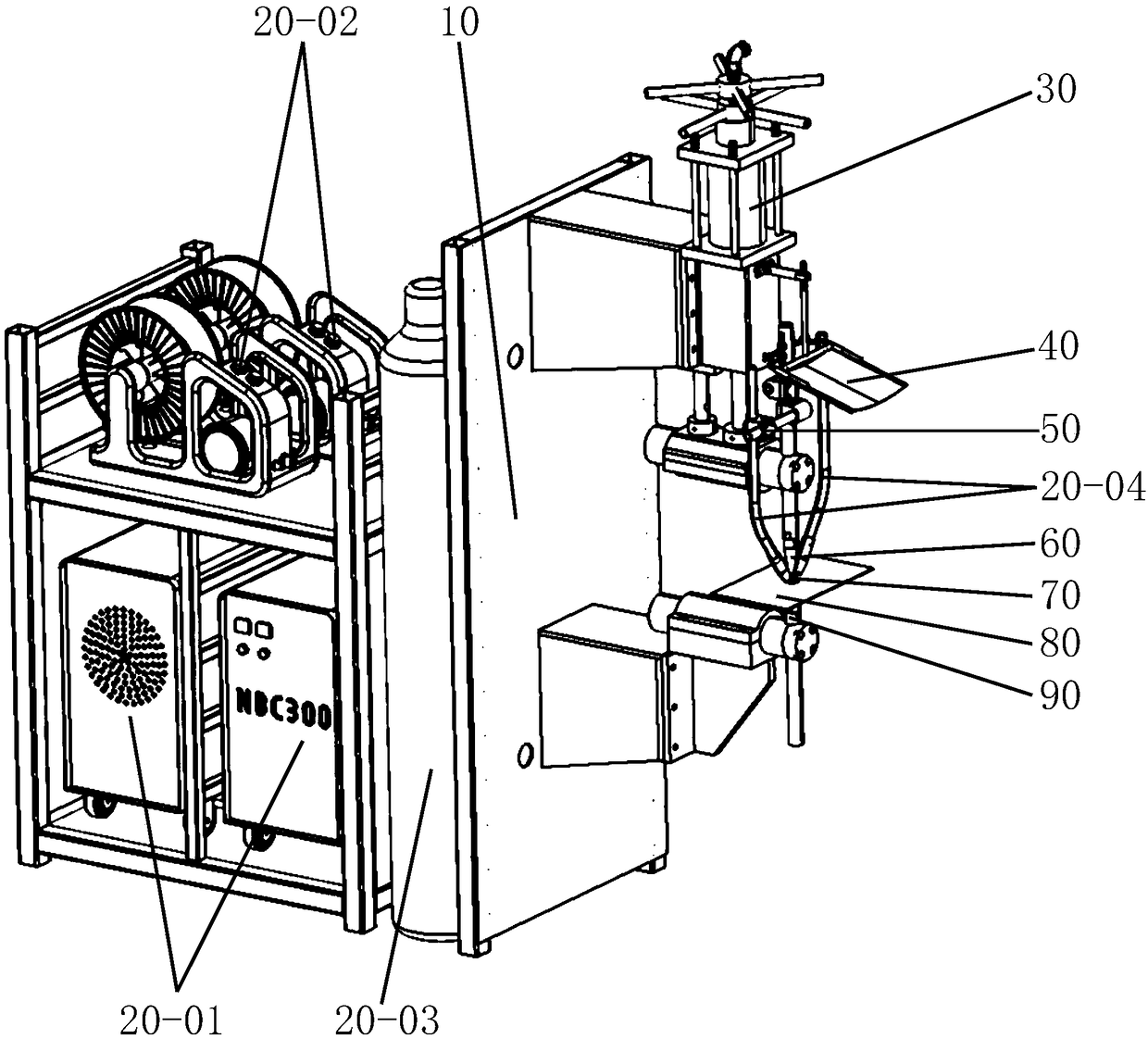

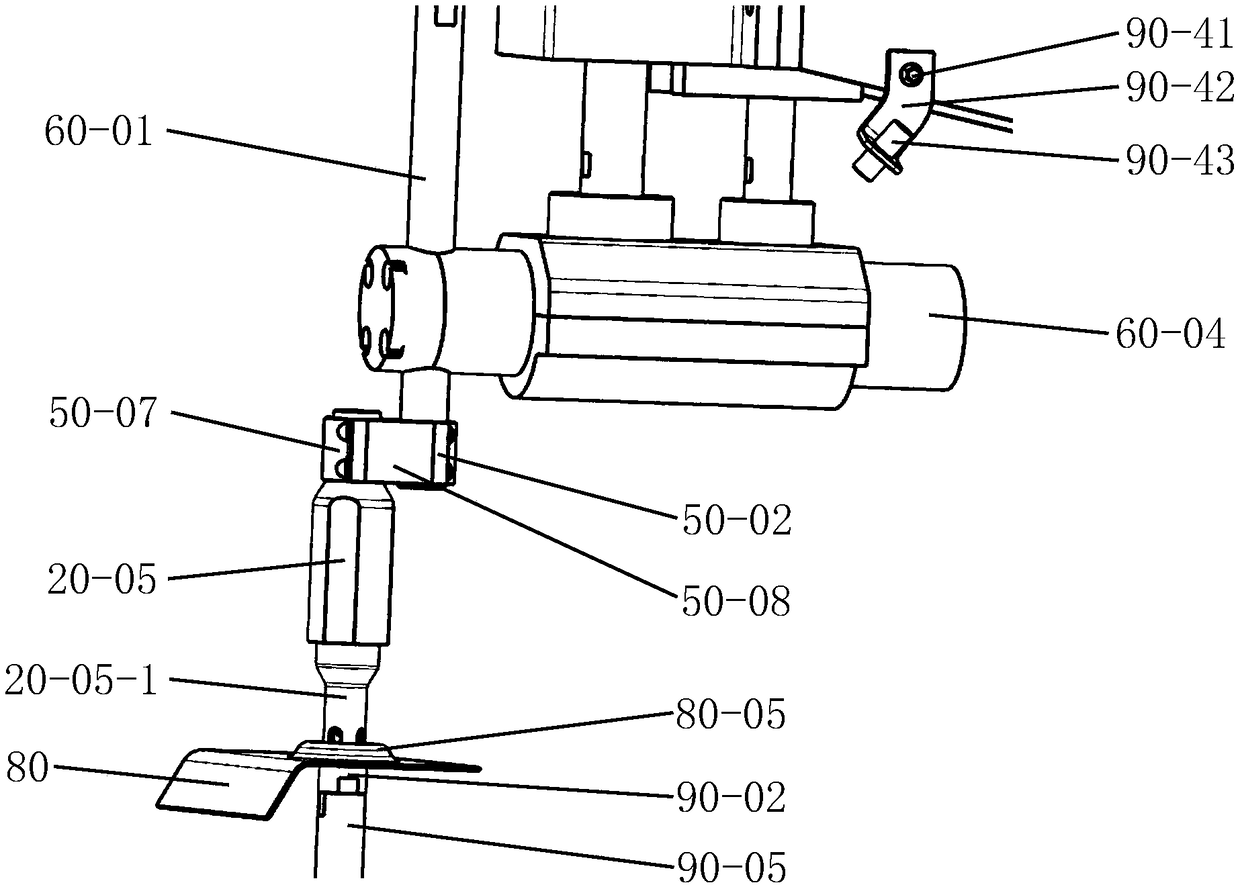

[0020] Embodiment 12: This embodiment is a technical solution for stud welding threaded fasteners, such as figure 2 . The stud welding here refers to a type of welding, not only applicable to the welding of studs, nuts can also be welded in this way. The welding place of workpiece (80) in this embodiment is divided into two types with holes and without holes, and the corresponding positioning cover (90-02) is also divided into two types with holes and without holes, and the positioning cover (90-02) without holes It is suitable for positioning the workpiece (80) without holes in the welding place, and the hole of the positioning cover (90-02) with holes is used for installing positioning pins, and is suitable for positioning the workpiece (80) with holes in the welding place.

[0021] First introduce the stud welding welding under the situation that the workpiece (80) welding place has no holes.

[0022] Stud welding gun (20-05) is made up of working end and pipeline (clamp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com