Umbrella-shaped tool magazine system

A tool magazine and umbrella-shaped technology, applied in the field of tool magazines, can solve problems such as lack of stability, and achieve the effect of reducing the floor space of the machine, good rigidity and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the drawings.

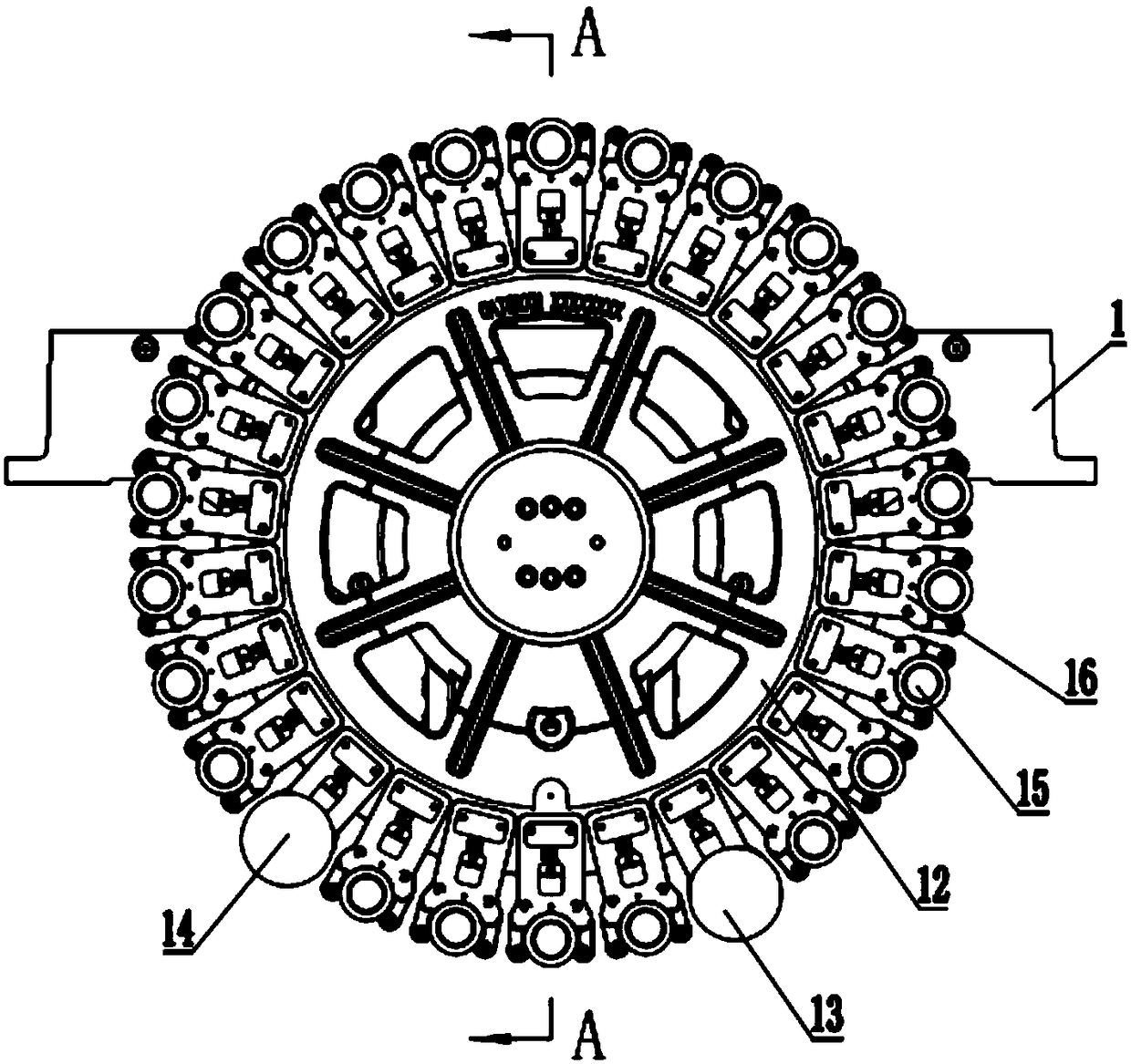

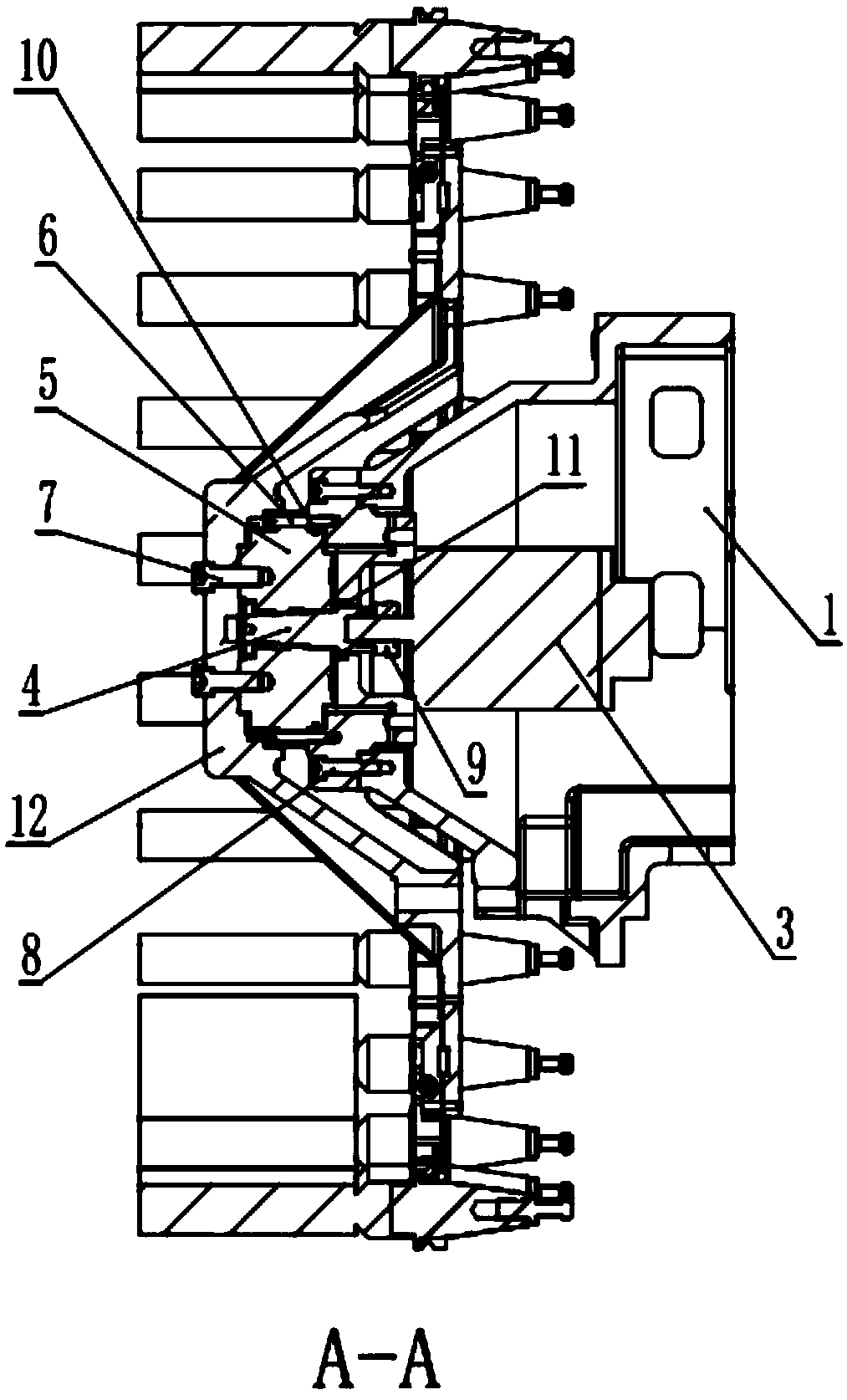

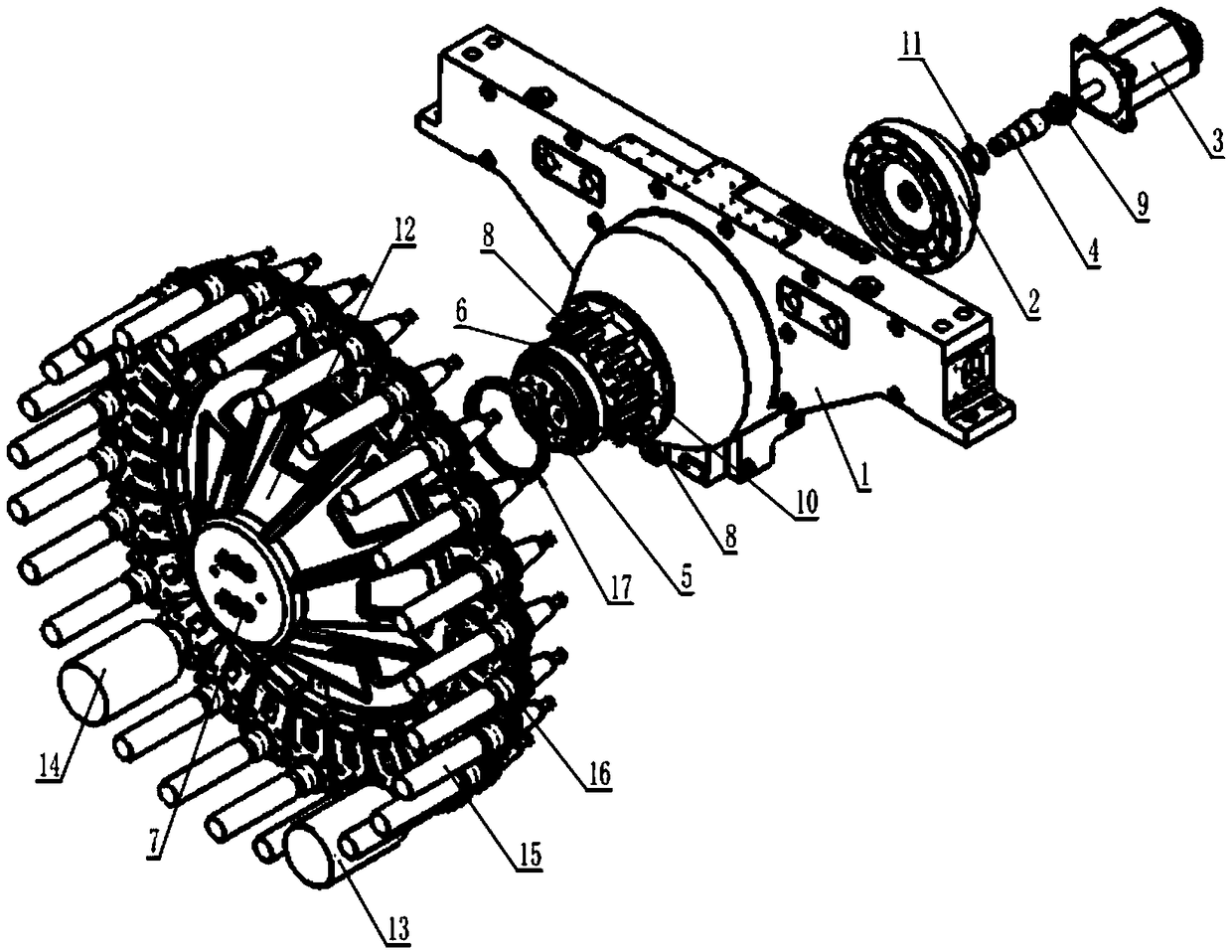

[0020] An umbrella-shaped tool magazine system, such as figure 1 , figure 2 with image 3 As shown, it includes umbrella-shaped tool magazine body 1, umbrella-shaped tool magazine motor plate 2, umbrella-shaped tool magazine motor 3, RV reducer input shaft 4, RV reducer 5, several bolts 6, several bolts 7, several bolts 8, Mechanical tightening sleeve 9, outer diameter static seal O-ring 10, sealing ring 11, umbrella-shaped tool magazine cutter head 12, tools 13-15, self-made BT40 tool holder 16, and skeleton oil seal 17. The RV reducer 5 includes the input shaft 4 of the RV reducer, two or three spur gears, an eccentric shaft with the same number of spur gears, two RV gears, an output shaft and a housing. One end of the input shaft is connected to the power source and the other end is provided There are input gears, all spur gears mesh with the input gears, a pair of spur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com