Automobile brake pad steel back grinding device

A brake pad and steel back technology is applied in the field of brake pad processing, which can solve the problems of poor structural stability, slow brake pad loading and unloading speed, affecting the effect of brake pad processing, etc., and achieves a stable structure, high safety, and improved quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

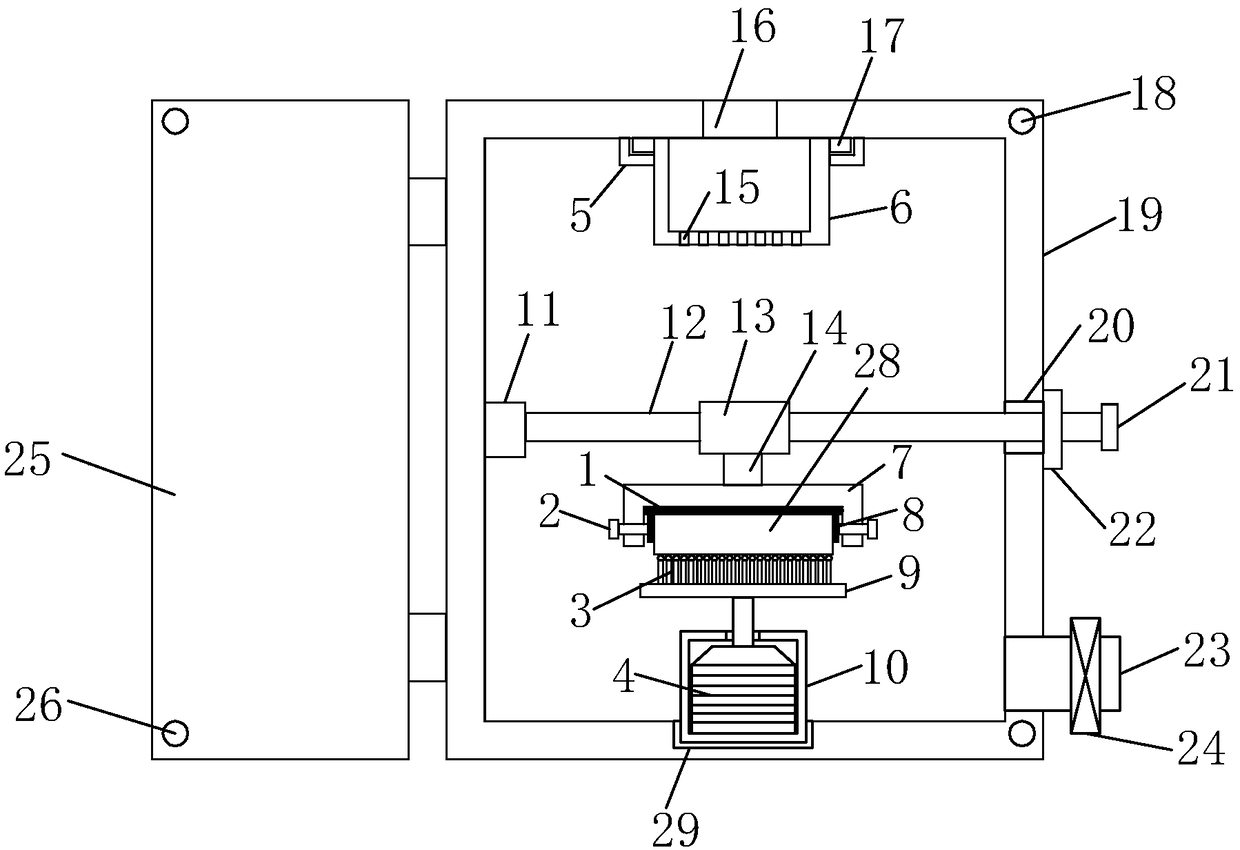

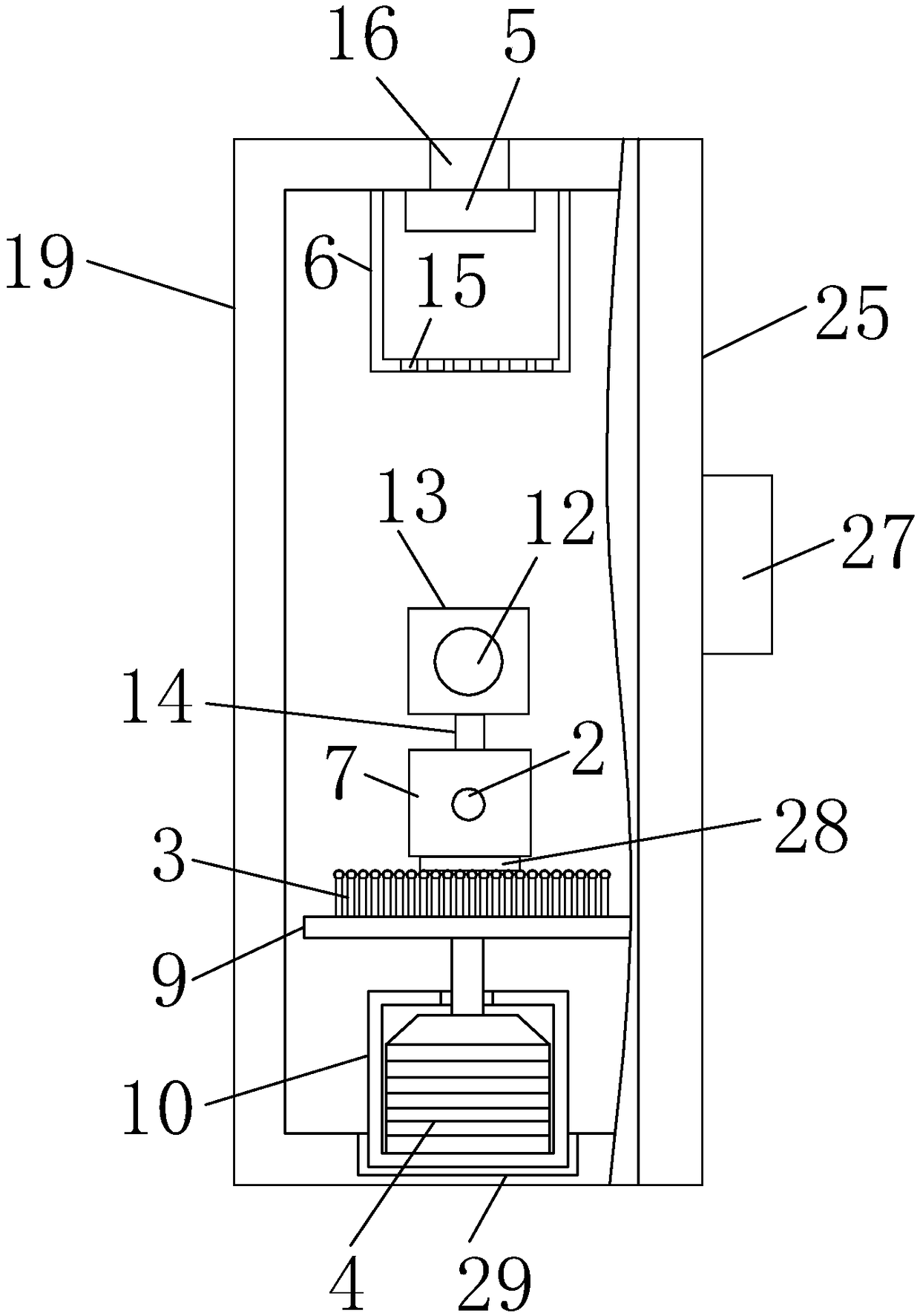

[0020] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0021] refer to Figure 1-2 , a steel back grinding device for automobile brake pads, comprising a box body 19, the middle part of the upper end of the box body 19 is provided with a water inlet 16 penetrating the box body 19, a box door 25 is hinged on one side of the box body 19, and the outer middle part of the box door 25 is fixedly installed There is a handle 27, and the design of the handle 27 can make it more convenient when the chamber door 25 is opened.

[0022] The lower end of one side of the casing 19 is equipped with an outlet pipe 23 that runs through the casing 19, and a valve 24 is also installed on the outlet pipe 23, and the box door 25 is engaged o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com