Tunnel lighting lamp maintenance robot and maintenance method

A tunnel lighting and robot technology, applied in manipulators, manufacturing tools, etc., can solve problems such as affecting the normal traffic operation of tunnels, hidden dangers of high-altitude operations, occupying a lane, etc., to achieve fast and efficient cleaning and maintenance, eliminate hidden safety hazards, and occupy a small space. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

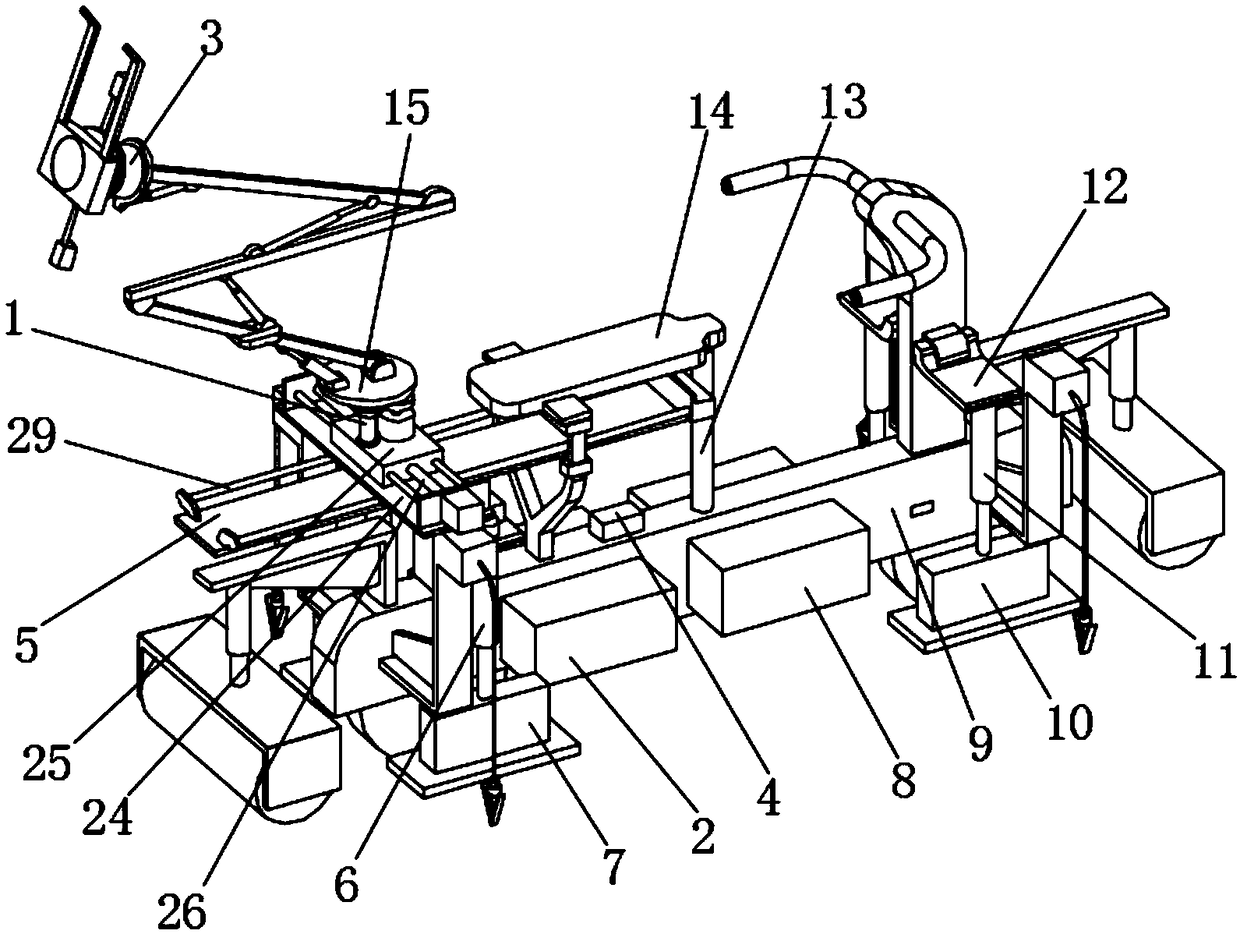

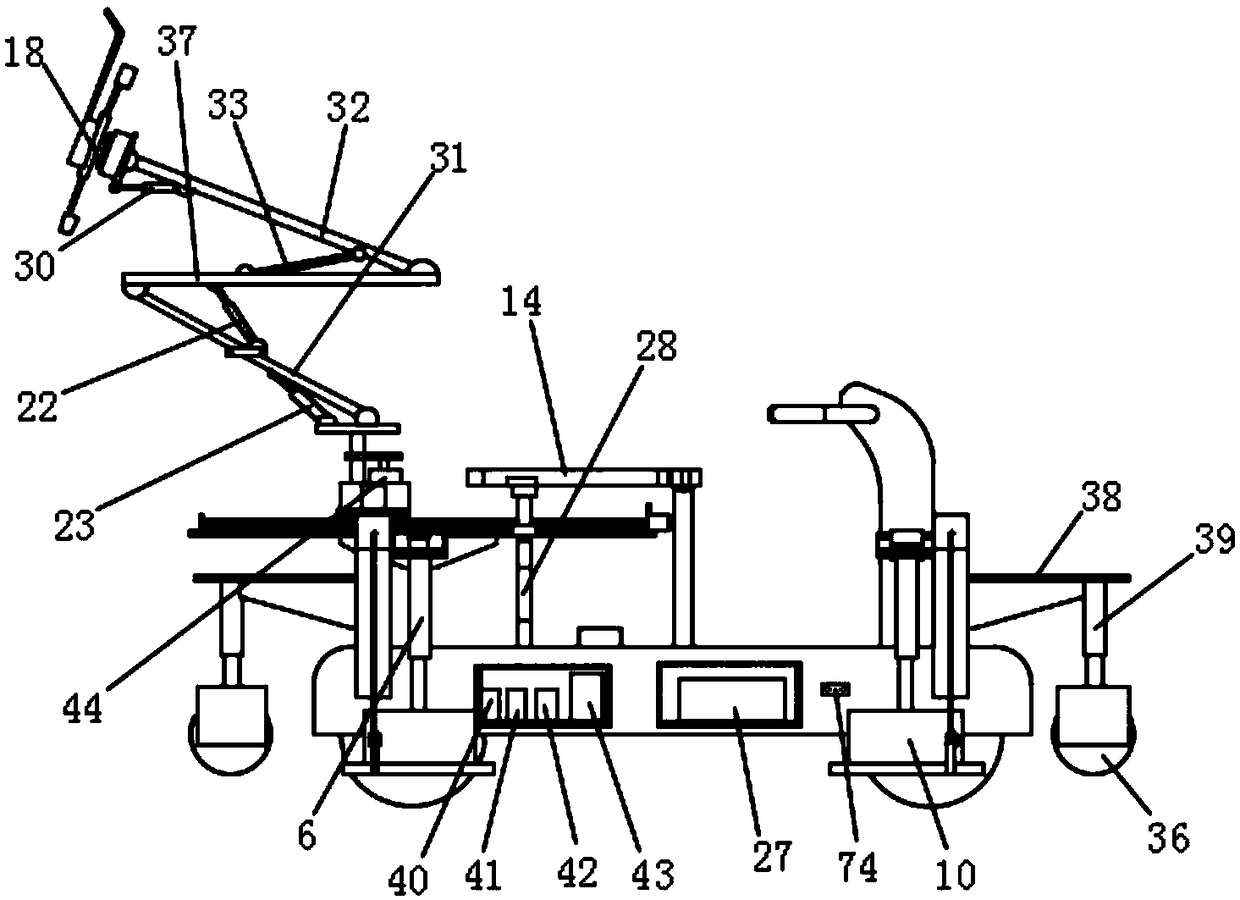

Embodiment 1

[0031]Embodiment 1: A maintenance robot for tunnel lighting lamps, including an electric car 9 and a scraping device 69, the scraping device 69 includes a scraper mounting plate 52, a micro liquid pump 53, a second cleaning agent storage tank 54, an atomizing nozzle 55 and silica gel The scraper 56, the front and rear ends of the right side of the scraper mounting plate 52 are provided with two symmetrically arranged third jaws. There is a waterproof power plug, the upper surface of the scraper mounting plate 52 is connected to the middle part of the lower surface of the second cleaning agent storage box 54 through a linear motor, the micro liquid pump 53 is arranged on the inner side bottom of the second cleaning agent storage box 54, and the silicone scraper Plate 56 is arranged on the middle part of the upper surface of the second cleaning agent storage tank 54, and the atomizing nozzle 55 is arranged on the upper surface of the second cleaning agent storage tank 54 near one...

Embodiment 2

[0032]Embodiment 2: A maintenance robot for tunnel lighting lamps, including an electric vehicle 9 and a cleaning device 72, the cleaning device 72 includes a first telescopic pallet 50, and the first telescopic pallet 50 is slidably connected by a third linear motor 48 arranged on its upper surface Cleaning plate 49 is arranged, and the left and right ends of the upper surface of cleaning plate 49 are provided with two first cleaning agent storage tanks 45 that are arranged symmetrically. The agent storage box 45 is connected with the electric roller brush 46 through the bearing that is arranged on its outer surface. The quantity of 46 is three, and three electric rolling brushes 46 are evenly distributed on the outer surface of the first cleaning agent storage tank 45 from front to back, and the outer surface of the electric rolling brushes 46 is provided with nozzles, and the inner surface of the first cleaning agent storage box 45 A liquid pump 51 is provided at the bottom...

Embodiment 3

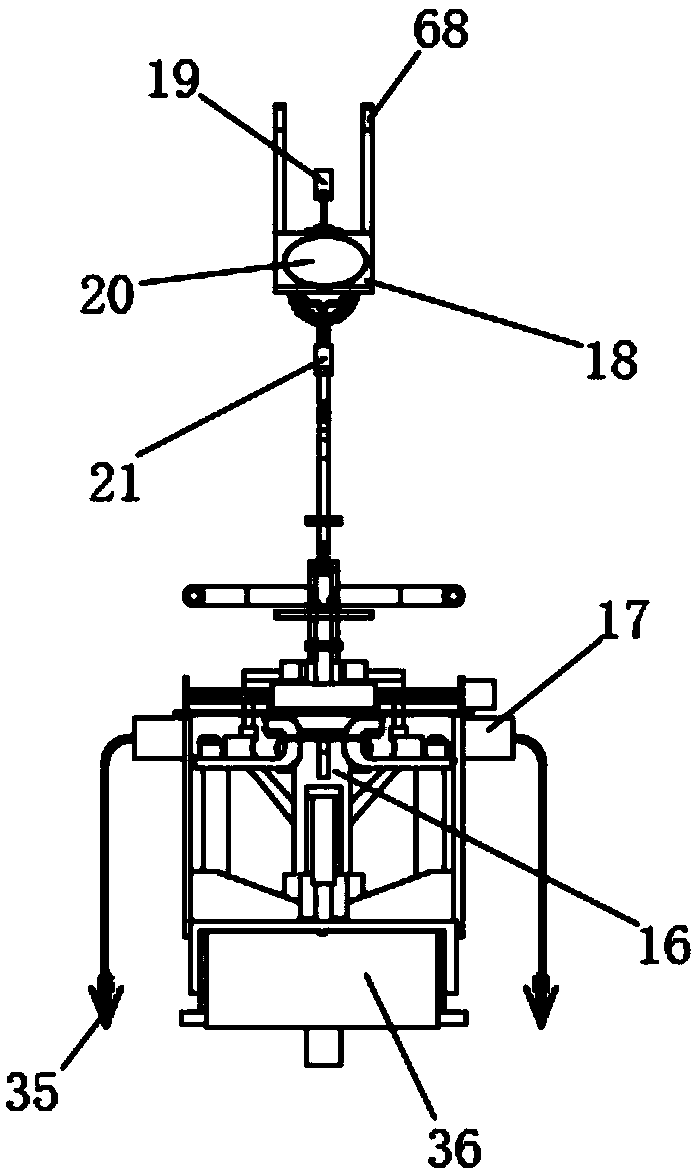

[0033] Embodiment 3: A maintenance robot for tunnel lighting fixtures, including an electric vehicle 9 and a replacement device 70, the replacement device 70 includes a quick release device mounting plate 57, a fifth electric telescopic rod 58, a top block 59 and a mechanical claw 60, and the quick release device The upper surface of the mounting plate 57 is provided with two left and right symmetrically arranged second positioning jaws on the front, rear, left and right sides. On the upper end surface of five electric telescopic rods 58, mechanical claws 60 are arranged on the left and right ends of the upper surface of the quick release device mounting plate 57, and the input end of the fifth electric telescopic rod 58 is electrically connected with the output end of the central processing unit 4, and the electric vehicle 9 A positioning post 13 is provided in the middle of the outer surface of the outer surface, and the positioning post 13 is connected with a seat plate 14 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com