Locomotive iron shoe management and control device, locomotive and alarming method and device

A technology for control devices and locomotives, applied to locomotives, transportation and packaging, railway car body parts, etc., can solve problems such as endangering driving safety and slipping accidents, and achieve the effects of reducing driving accidents, improving safety, and standardizing placement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

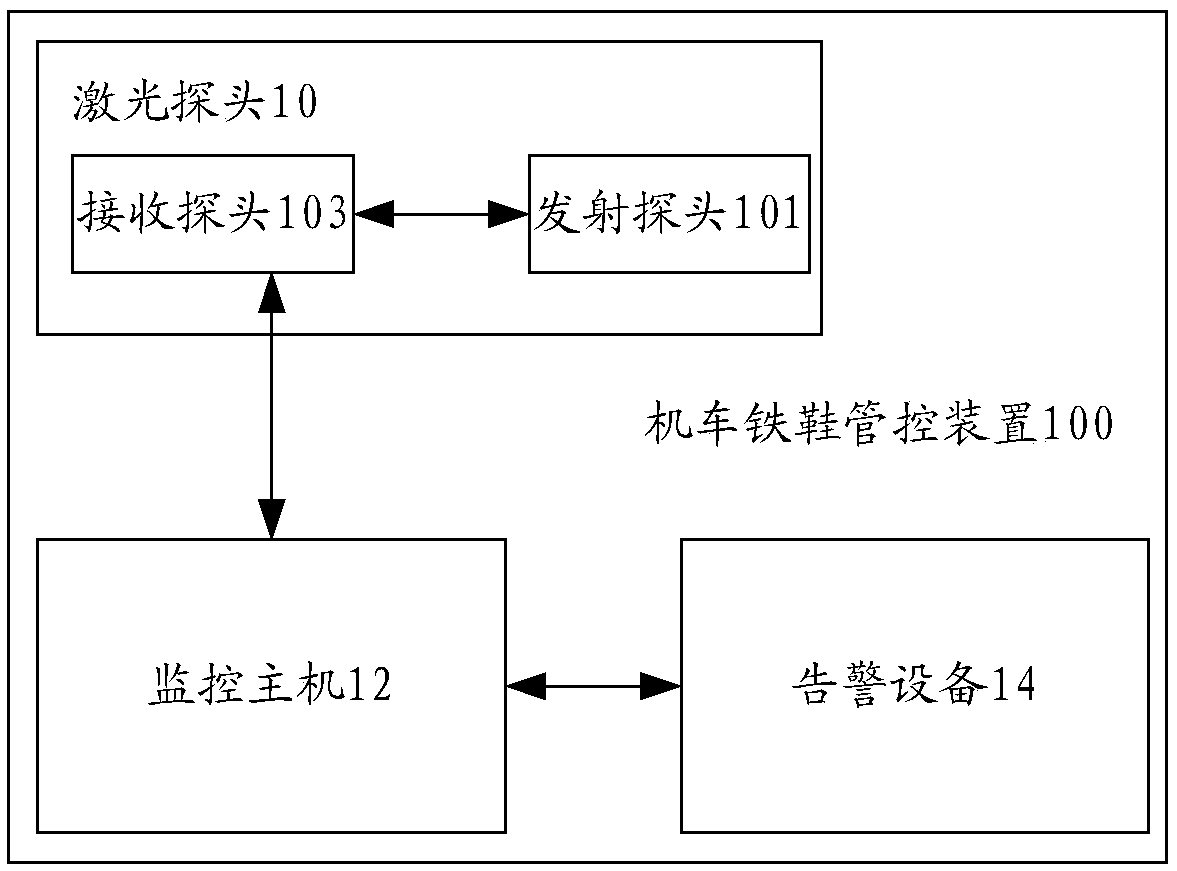

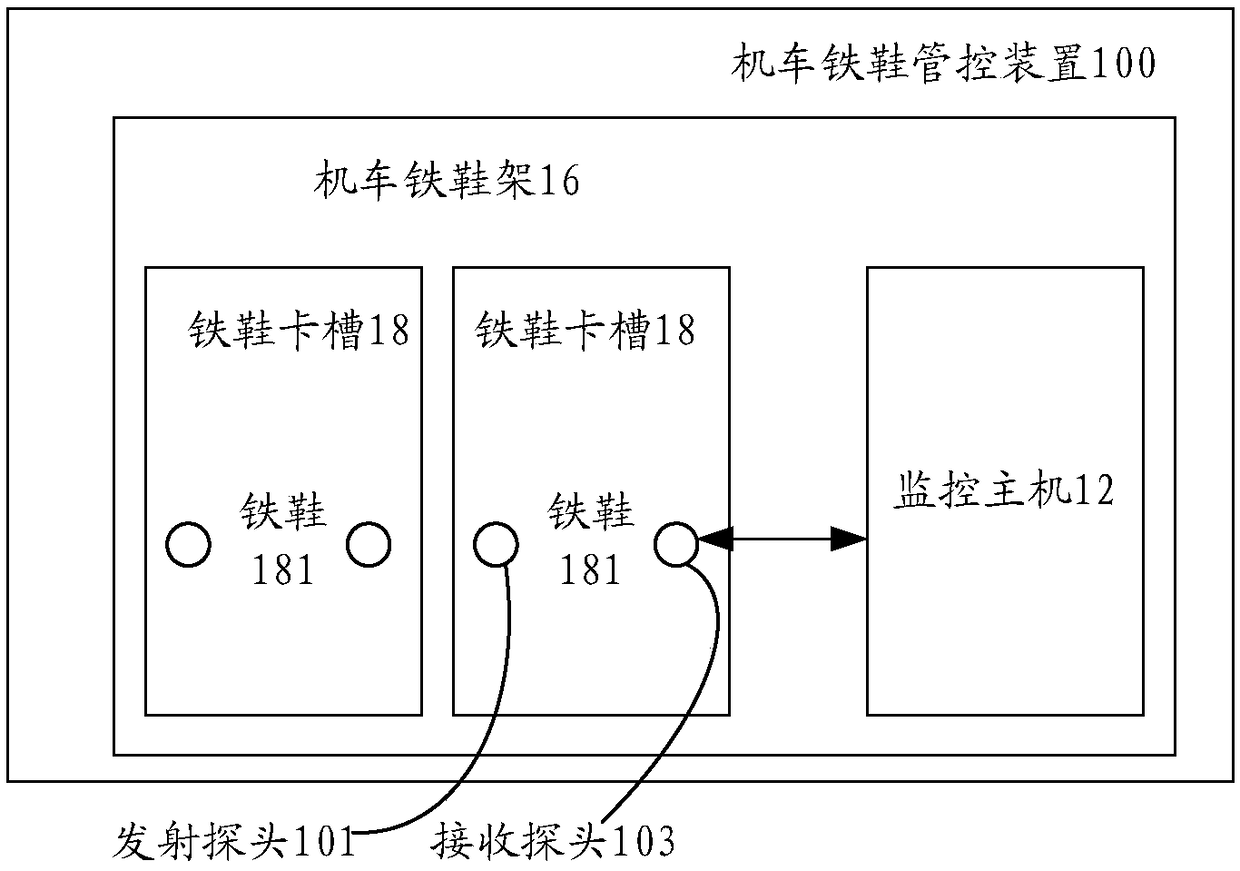

[0036] According to an embodiment of the present invention, an embodiment of a control device for locomotive iron shoes is provided, figure 1 It is a structural schematic diagram of a locomotive iron shoe management and control device according to an embodiment of the present invention, as shown in figure 1 As shown, the above-mentioned locomotive iron shoe management and control device 100 includes: a laser probe 10 (transmitting probe 101 and receiving probe 103), a monitoring host 12, and an alarm device 14, wherein:

[0037] The laser probe 10 is arranged inside the iron shoe card slot on the locomotive iron shoe rack, and includes a transmitting probe 101 for sending out a laser beam and a receiving probe 103 for receiving the above-mentioned laser beam; the monitoring host 12 is connected to the above-mentioned receiving probe, The main control system of the locomotive is connected to detect the state signal of the above-mentioned laser beam received by the receiving pro...

Embodiment 2

[0067] According to the embodiment of the present invention, another embodiment of the control device for locomotive iron shoes is provided, Figure 4 It is a structural schematic diagram of another locomotive iron shoe management and control device according to an embodiment of the present invention, such as Figure 4 As shown, the locomotive iron shoe management and control device 400 includes: a laser probe 40 (transmitting probe 401 and receiving probe 403), a monitoring host 42 and an alarm device 44, wherein:

[0068] Laser probe 40 is arranged on the inside of the iron shoe card slot on the iron shoe rack of the locomotive, and includes a transmitting probe 401 for sending out a laser beam and a receiving probe 403 for receiving the above-mentioned laser beam; 1. The main control system of the locomotive is connected to detect whether the above-mentioned receiving probe receives the laser beam sent by the above-mentioned transmitting probe, and whether the above-mention...

Embodiment 3

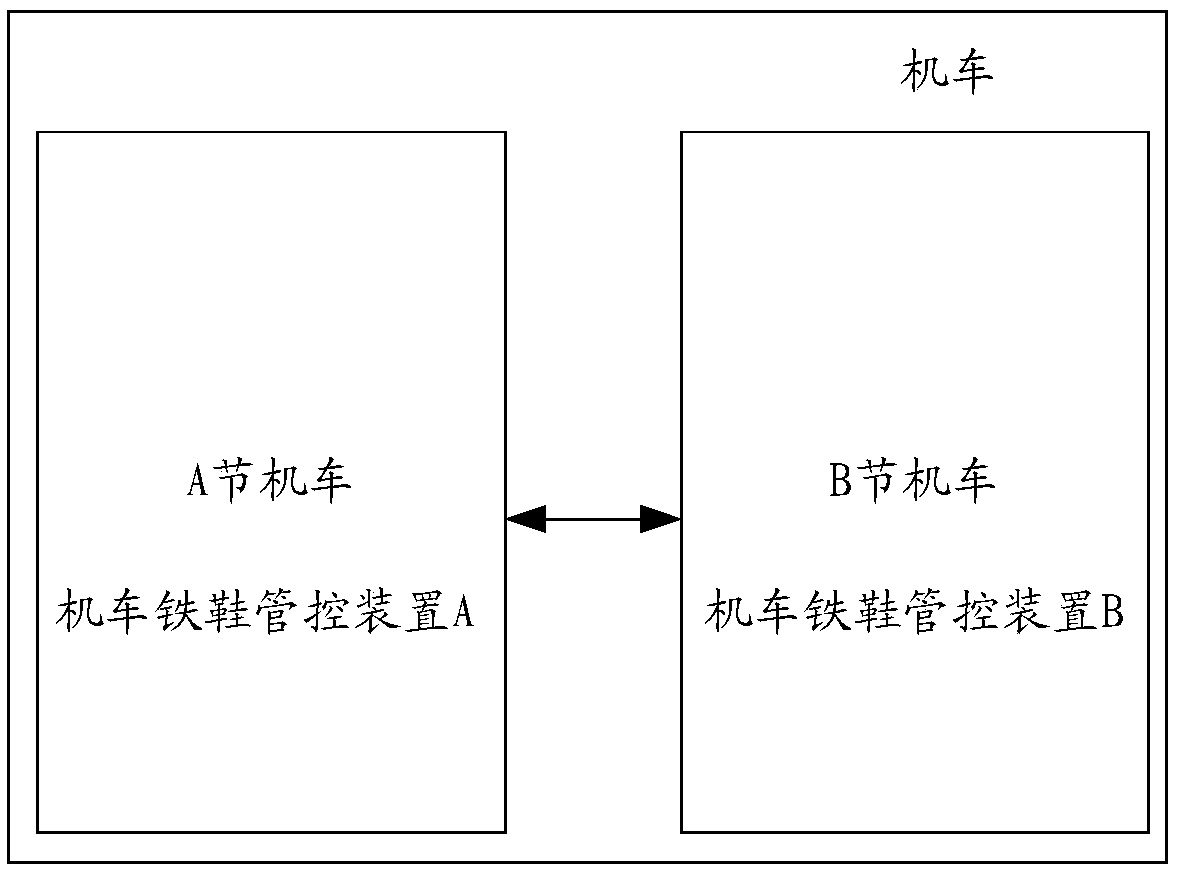

[0081] According to an embodiment of the present invention, an embodiment of a locomotive is also provided, including any one of the locomotive iron shoe management and control device in Embodiment 1 and Embodiment 2 above.

[0082] In an optional embodiment, the above-mentioned locomotive includes: a first locomotive and a second locomotive; The locomotive iron shoe rack is arranged inside the above-mentioned first locomotive, and the above-mentioned second locomotive iron shoe rack is arranged inside the above-mentioned second locomotive.

[0083] As an optional embodiment, a train of locomotives may include: a first locomotive and a second locomotive, and the first locomotive iron shoe rack and the second locomotive iron shoe rack (the carrier of the locomotive iron shoe management device) can be installed respectively, For example, an iron shoe rack can be installed in the first locomotive, and an iron shoe rack can be installed in the second locomotive to manage the iron ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com