Manufacturing method for saddle frame for placing two layers of steel coils on large storage area

A manufacturing method and technology of saddle racks, which are applied in the field of warehouse storage and logistics placement, can solve the problems of collapse of double-layer rolls, increased labor intensity, and accidents caused by personal injury, so as to reduce breakage and looseness, save energy and waste, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

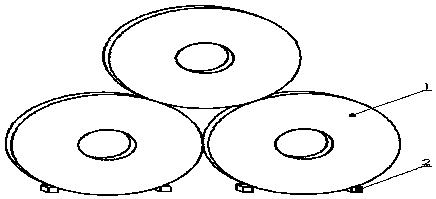

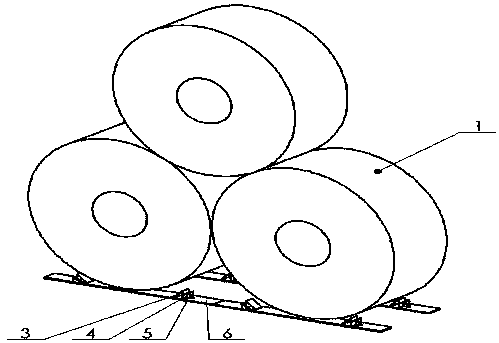

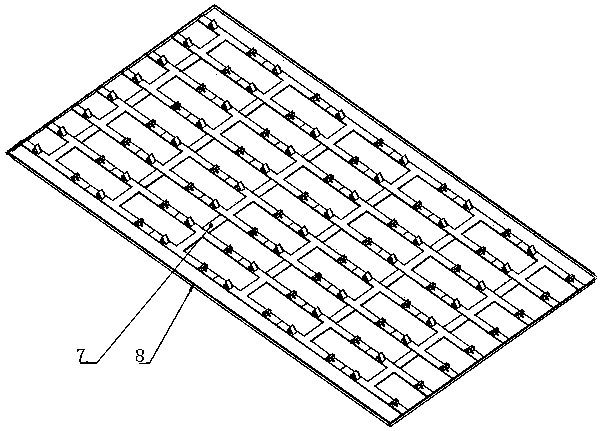

[0018] Embodiment 1: see figure 2 , image 3 , a method for manufacturing a saddle frame for placing two layers of steel coils in a large warehouse, the method includes the following steps:

[0019] 1) Fixed and welded steel rails to form a rectangular storage area, using steel plates of a certain thickness and width, the length is determined according to the actual size of the stacked site storage area, welded with the rails as a whole, cut into two long steel plates, and used in the middle The connecting plate is welded and assembled, and the width of the connecting plate is 900mm;

[0020] 2) Cut 16# channel steel into a specified size at a suitable position on each long steel plate and weld it on the long steel plate. The outer side of the 16# channel steel is welded with the rib plate of the triangle, and the inner side is placed with a triangular skid, 16# The two sides of the inner groove of the channel steel are at an angle of 45 degrees, which are closely matched w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com