Environment-friendly operation vehicle for park maintenance

An environment-friendly and operating vehicle technology, applied in the field of gardens, can solve problems such as chains are easy to fall off and damaged, difficult to break through structural restrictions, unreasonable opening and closing methods, etc., and achieve the effect of reasonable structural layout, novel structural design and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

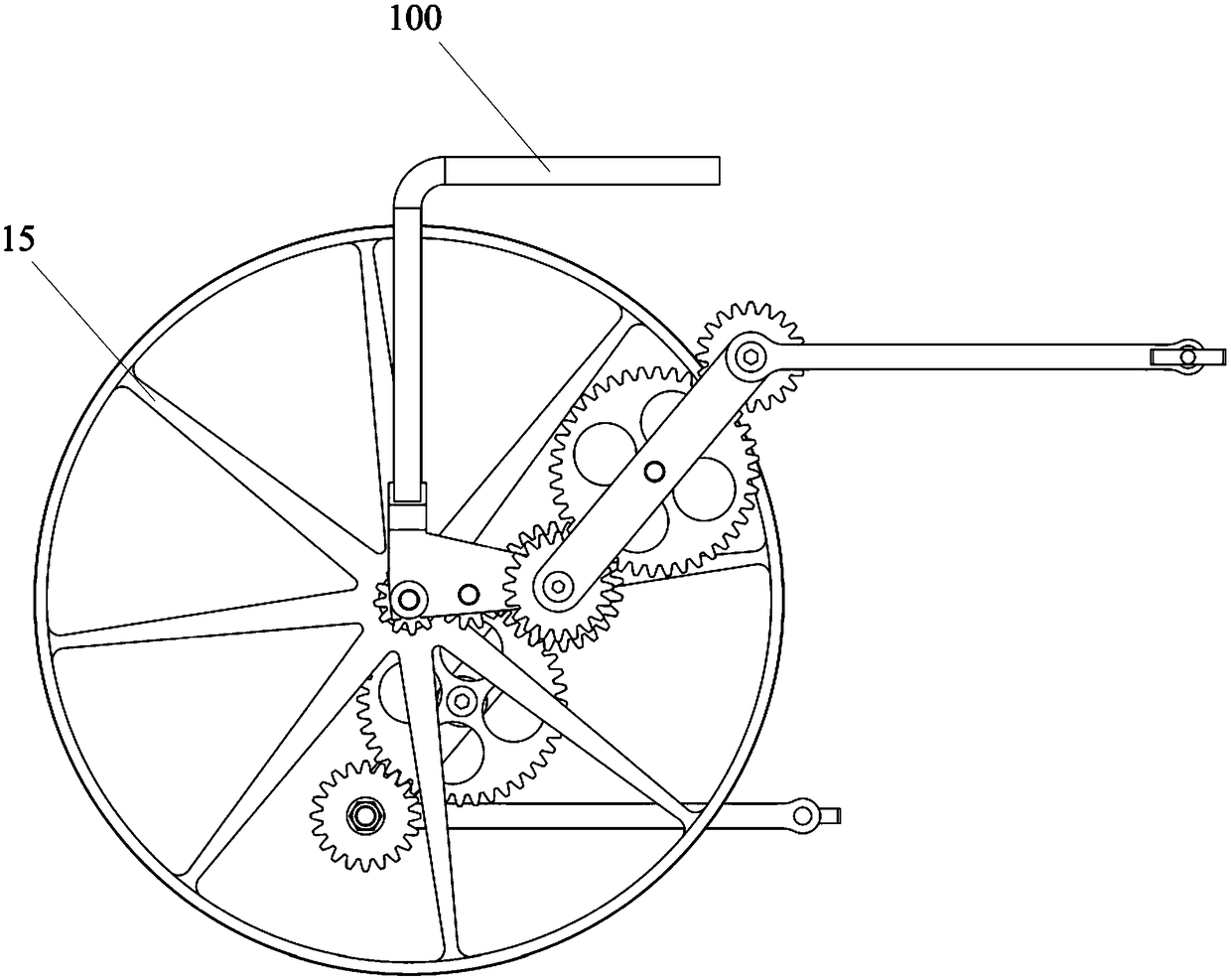

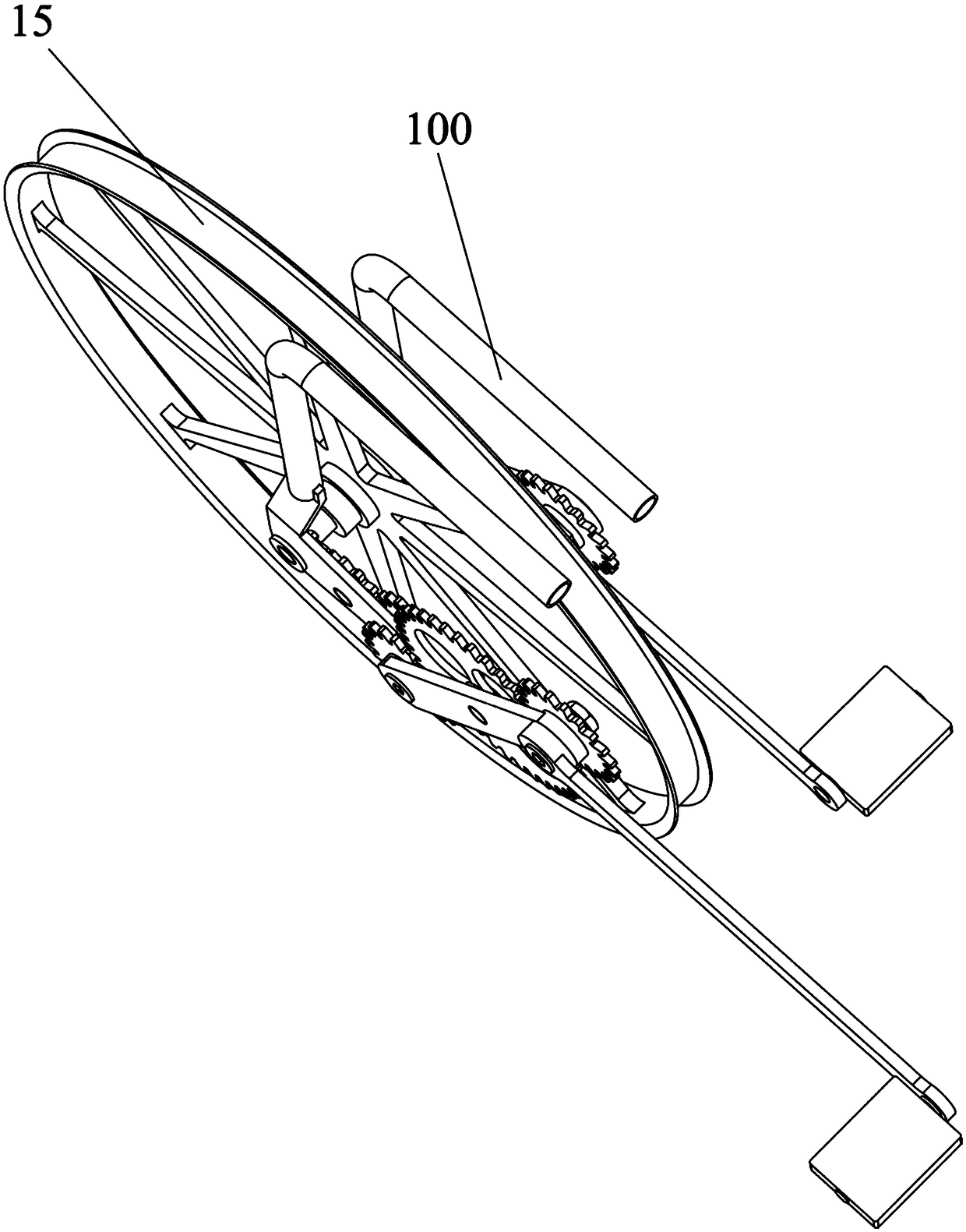

[0021] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0022] For ease of description and illustration, figure 1 The right direction in the figure refers to the front, front end, front and forward direction of the whole mechanism, figure 1 The left direction in the figure is the rear, rear end, rear and backward direction of the whole mechanism.

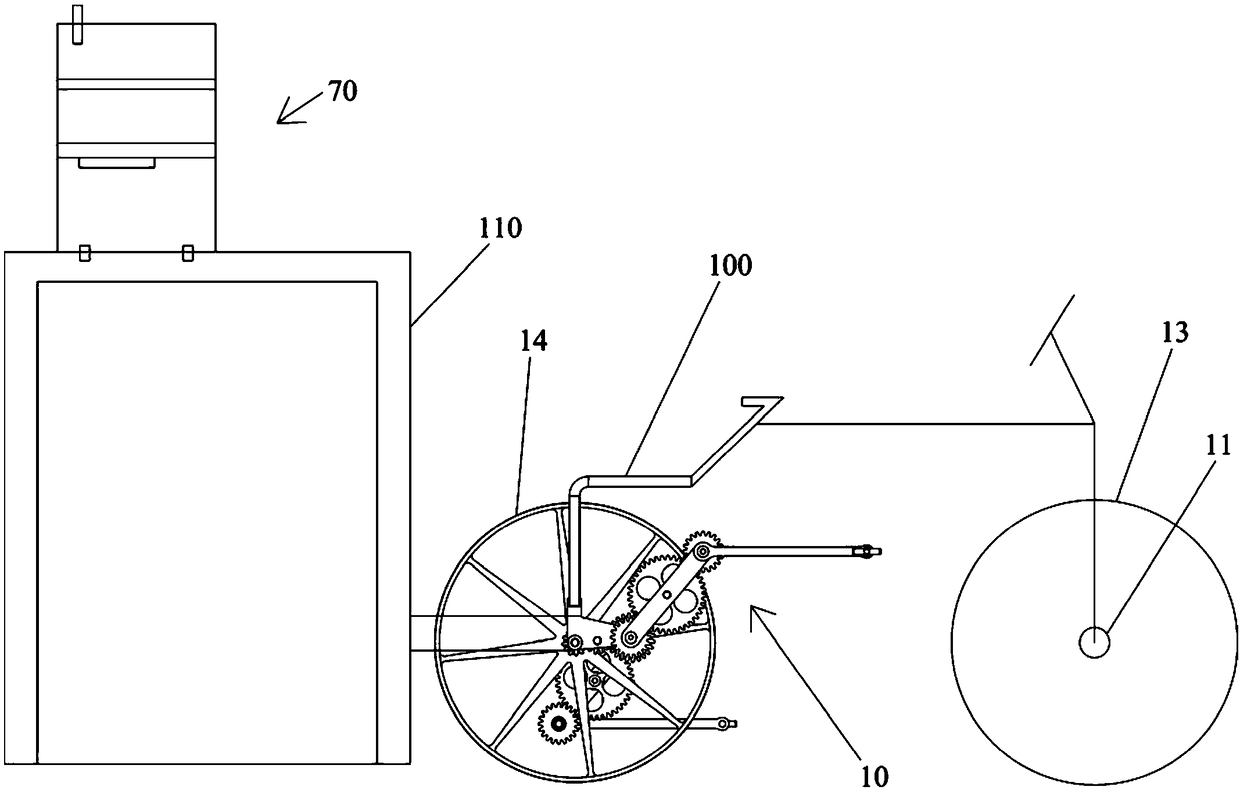

[0023] Such as Figure 1 to Figure 6 As shown, the embodiment of the present invention provides an environment-friendly garden maintenance work vehicle, which includes a vehicle frame 100 and a box body 110 arranged on the vehicle frame 100, and the vehicle frame 100 is provided with a front axle 11 and a rear axle 12, The front axle 11 is rotatably provided with a front wheel 13, and the rear axle 12 is rotatably provided with a rear wheel 14. The bottom of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com