Variable speed chain wheel assembly

A technology for shifting sprockets and components, which is applied to vehicle gearboxes, vehicle components, chain/belt drives, etc., can solve the problems that the gearbox cannot be made too large, the size of the speed change gear is limited, and the size of the transmission ratio is limited. The effect of low cost, small footprint and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

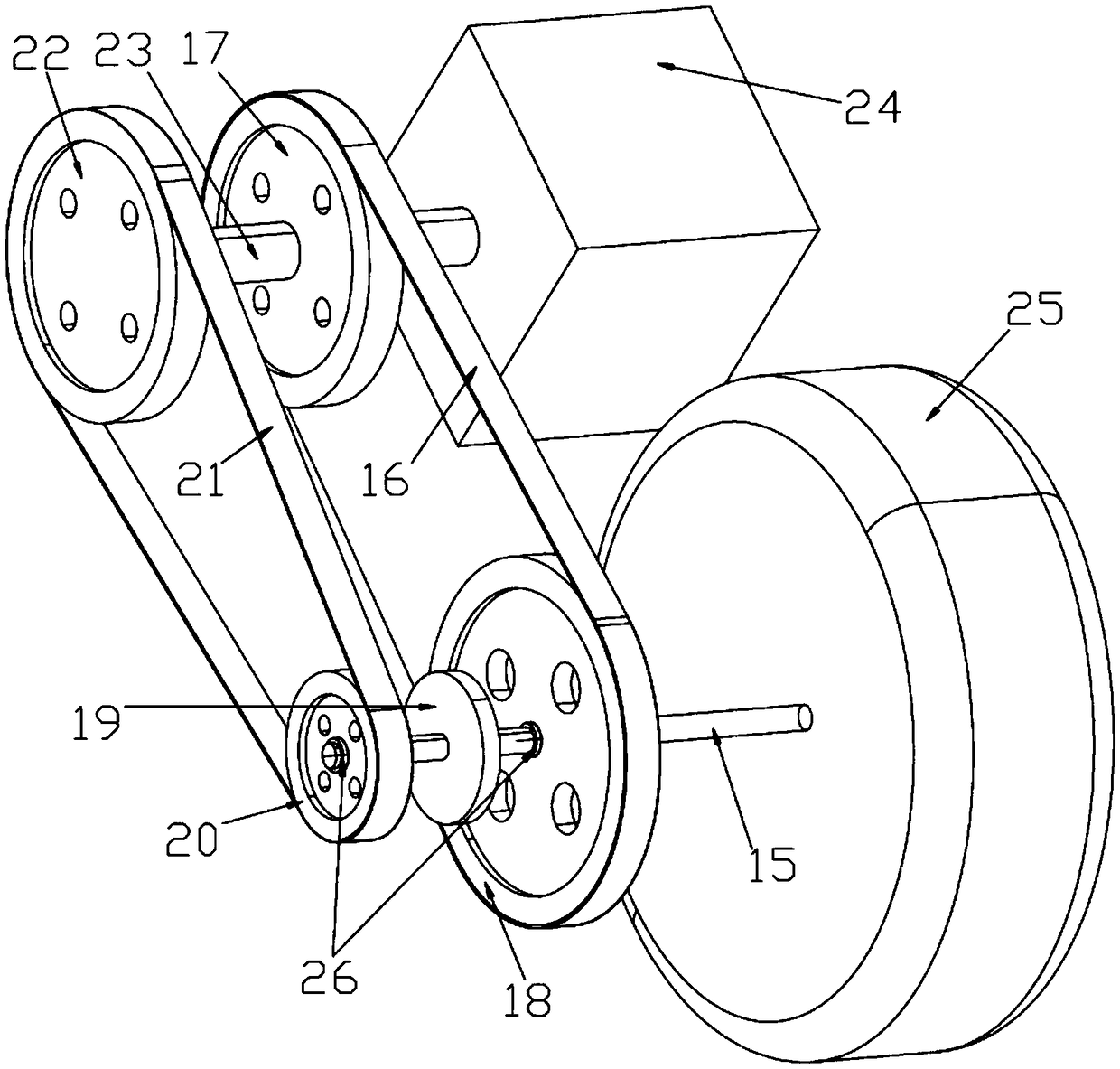

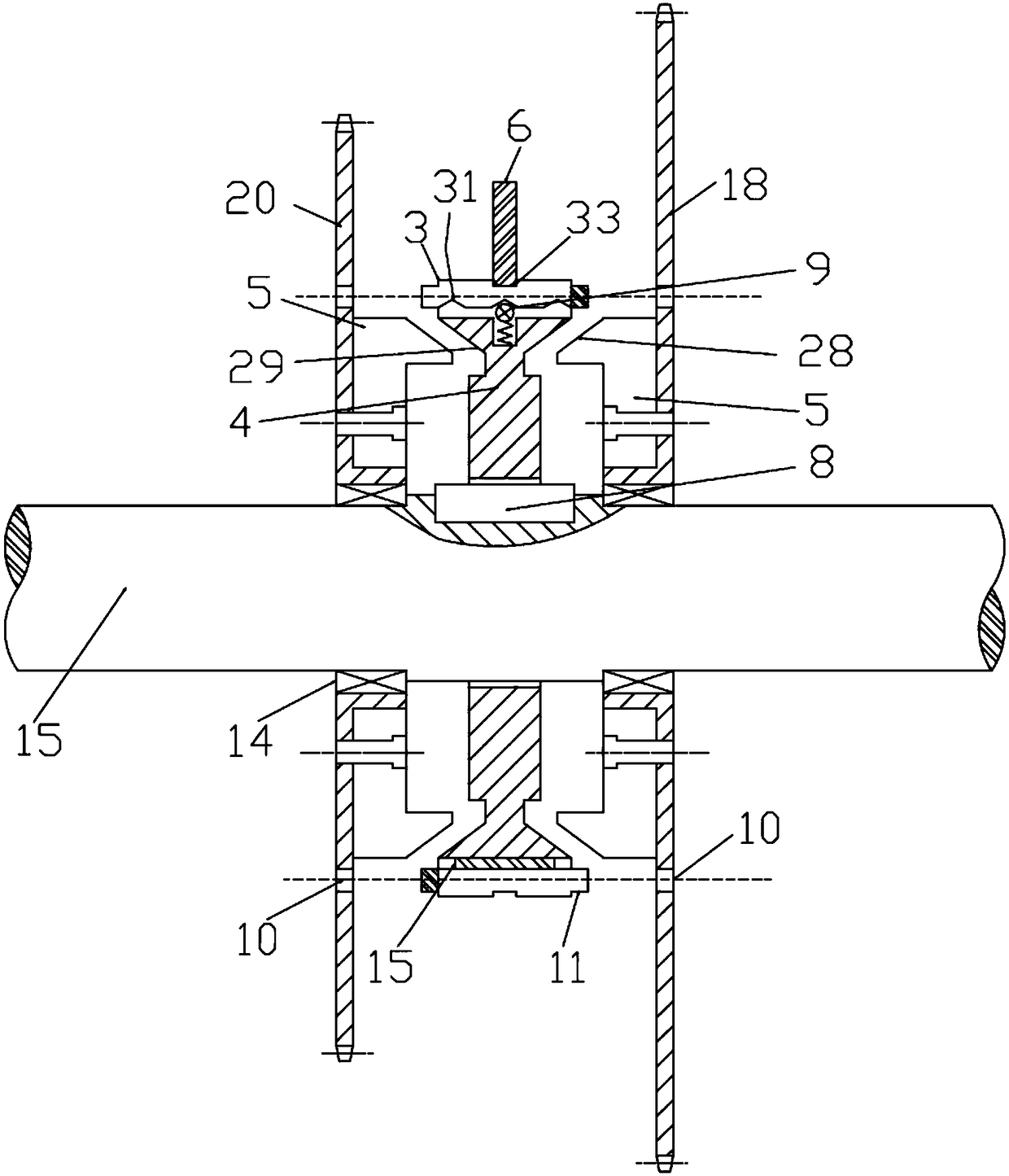

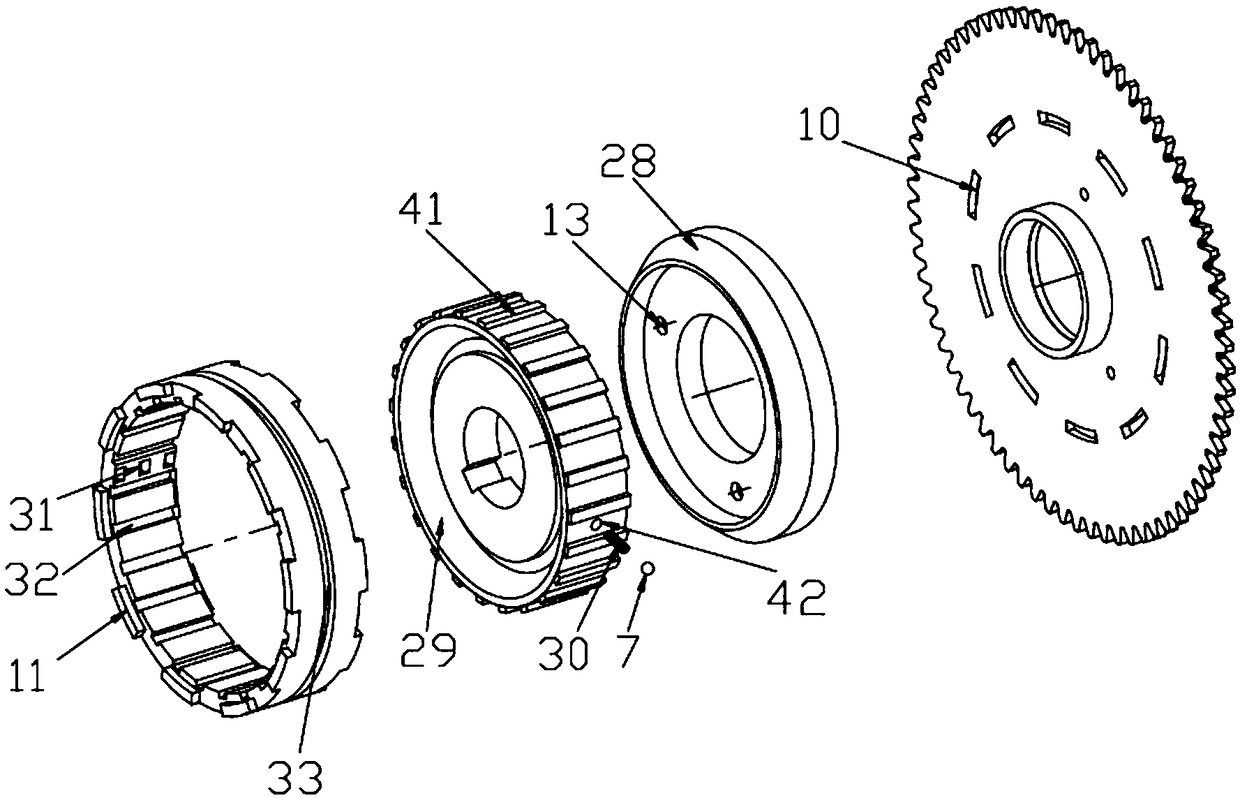

[0018] Such as Figure 1-Figure 3 As shown, the variable speed sprocket assembly described in this embodiment includes a gearbox 24 and an output shaft 15 on which wheels 25 are installed. The output shaft 15 is driven to rotate by the gearbox 24, and a drive Sprocket one 17 and driving sprocket two 22, the output shaft 15 is fixed with large sprocket 18 and small sprocket 20 by bearing 26 sleeve socket, large sprocket 18 is driven to rotate by chain by driving sprocket one 17, small sprocket 20 is rotated by driving sprocket 2 22 through the chain drive; the output shaft 15 is equipped with a synchronous shift mechanism 19 that impels the small sprocket 20 or the large sprocket 18 to rotate synchronously and then shifts gears. The synchronous shift mechanism 19 is displaceable. The limit is on the output shaft 15, and the synchronous shift mechanism 19 is located between the large sprocket 18 and the small sprocket 20; The output shaft 15 rotates when the large sprocket 18 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com