Service plate turnover device

A dinner plate and overturning technology, which is applied in the direction of transportation and packaging, conveyors, conveyor objects, etc., can solve the problems of falling on the floor, stacking, and reducing the labor intensity of canteen staff, so as to improve work efficiency and reduce Labor intensity, the effect of improving the speed of recycling and cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of the present invention is further described below, but the scope of protection is not limited to the above.

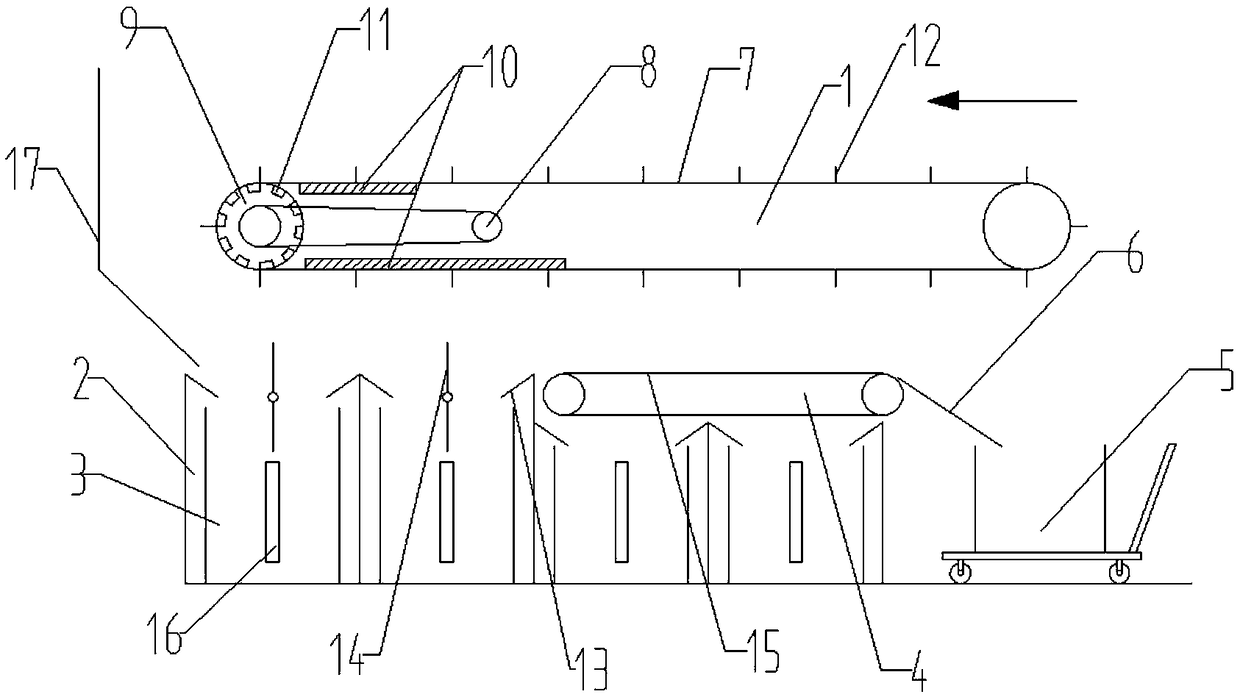

[0018] Such as figure 1 As shown, a dinner plate overturning device includes a dinner plate conveyor A1, a meal collection tank 2, a collection bucket 3, a dinner plate conveyor B4, and a dinner tray collection vehicle 5. The meal collection tank 2 is installed on the dinner plate transfer Below the machine A1, the food collection tank 2 is divided into four single compartments, the plate conveyor B4 is installed above the third and fourth single compartments, and the collection bucket 3 is installed in the single compartment of the food collection tank 2 , The plate conveyor B4 is provided with an inclined slide plate 6 on one side, and the plate collection cart 5 is placed under the inclined slide plate 6. When the device is working, the plate is placed on the conveyor belt A7 of the plate conveyor A1. The conveyor belt A7 is equipped wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com