Method for stoping mountainside type tailings pond

A technology for tailings pools and tailings, which is applied in mining equipment, mining equipment, earth cube drilling, etc. It can solve the problems of large labor input and equipment maintenance costs, large labor and equipment investment, and increased mining cycle, so as to shorten mining The effect of reducing the construction period, reducing the mining cost and speeding up the mining speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with embodiment:

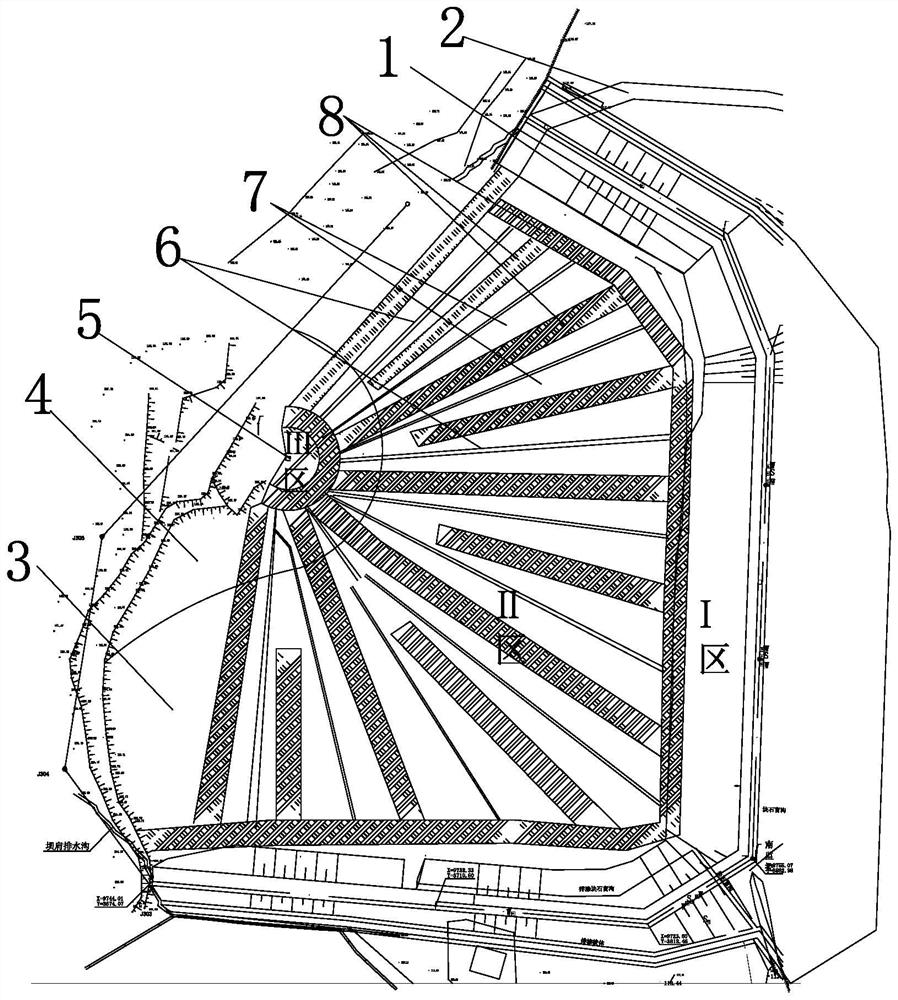

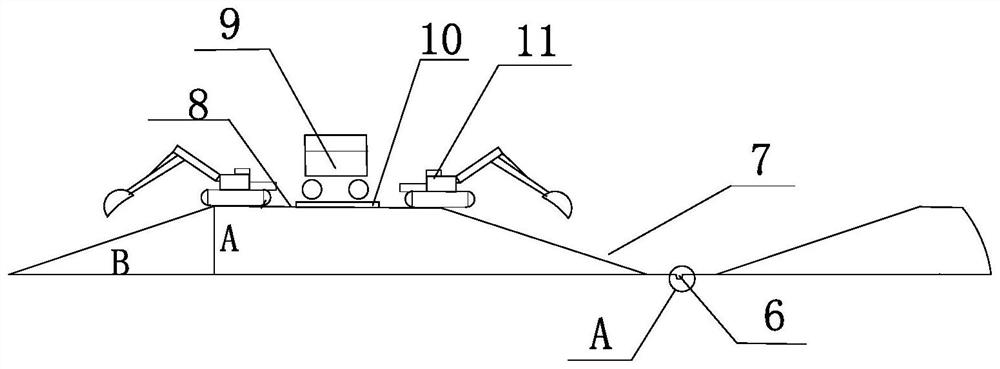

[0026] Such as Figure 1~3 As shown, the mining method of the side-mountain type tailings pond of the present invention comprises the following steps:

[0027] Step 1) Tailings Pond Exploration: The tailings pool is currently in a state of suspension, and the tailings pool is divided into a dry area 3 and a cracked and wet area 4. Conduct systematic investigations on the topography of the deposit, the stability of the stockpiling dam body, the particle size composition and moisture content of the tailings in the wet area, and provide basic information for the dry tailings mining.

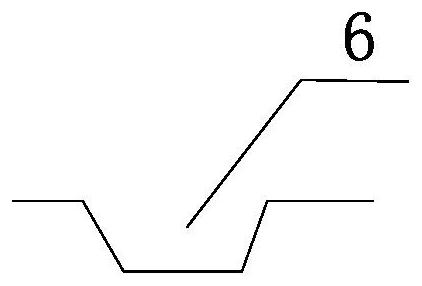

[0028] Step 2) Mining area division and parameter determination: According to the survey report, the tailings sand in the tailings reservoir area mainly includes tailings silt, tailings silt, and tailings silty clay. The physical and mechanical indicators of the tailings in the area in front of the dam o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com