Waste rotary kiln degradation sewage anaerobic purification combined device

A combined device and garbage degradation technology, applied in biochemical instruments, biochemical equipment and methods, gas production bioreactors, etc., can solve the problems of costly human resources, infiltration of garbage and waste liquid, and difficult treatment, etc., to achieve garbage degradation High benefit, low device cost, no damage to water source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

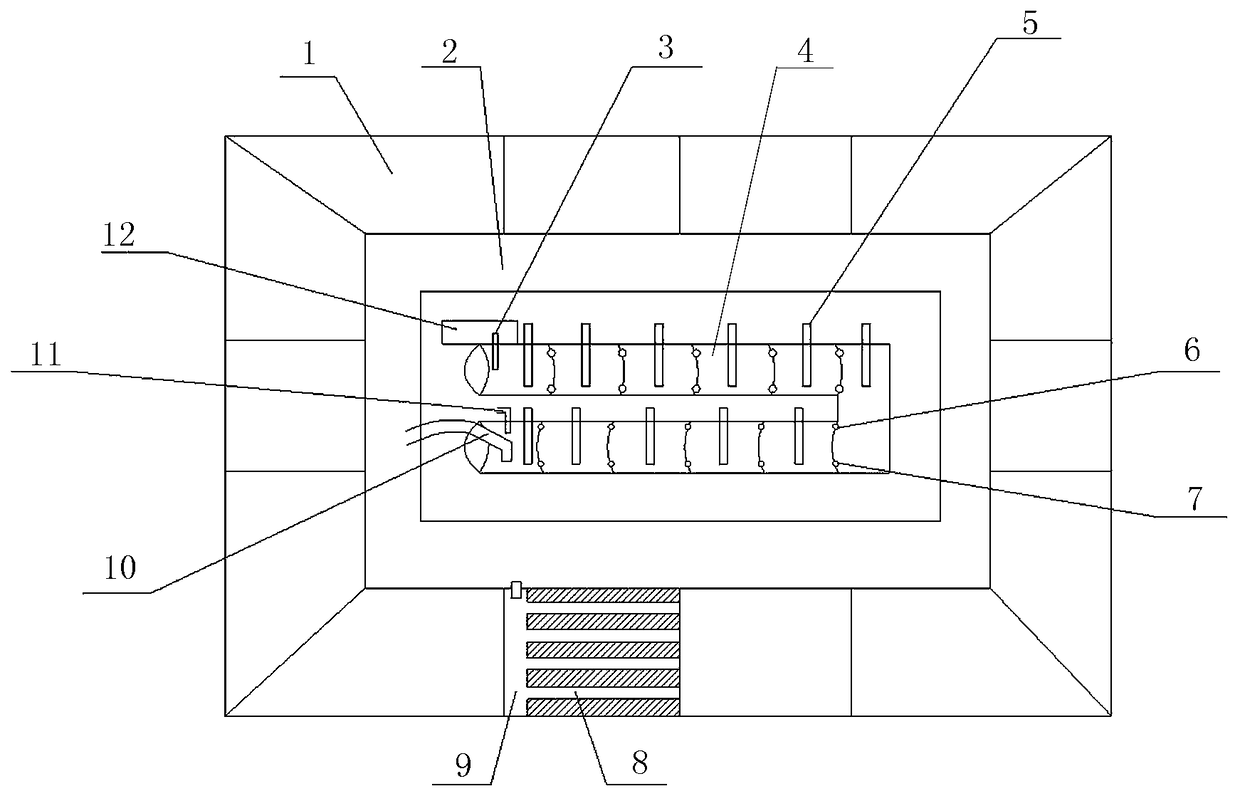

[0025] Such as figure 1 As shown, a garbage rotary kiln degradation sewage liquid oxygen submerged purification combination device includes a fermentation part and a rotary kiln degradation part arranged around the fermentation part, and a first-stage drainage channel 2 is provided between the fermentation part and the rotary kiln degradation part;

[0026] The fermentation part includes several stages of fermentation cylinders 4; the adjacent fermentation cylinders 4 are connected through the water holes 7 in the lower part of the cylinder wall, and the upper middle part of the cylinder wall between the adjacent fermentation cylinders 4 is also provided with ventilation holes. 6. The first-stage fermentation cylinder is provided with a water inlet 10 and an exhaust port 11. The water inlet 10 is connected to the first-stage drainage channel 2 through a pipeline, and the exhaust port 11 is connected to the air pipe joint; the top of each stage of fermentation cylinder 4 is prov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com