Self-clamping column type connector assembly type prefabricated underground continuous wall

An underground diaphragm wall and prefabricated technology, which is applied in excavation, construction, infrastructure engineering, etc., can solve the problems that the wall enclosure function cannot be fully exerted, the quality of joint grouting is difficult to control, and the integrity of the diaphragm wall is reduced. Achieve strong practical value and application prospects, avoid plugging difficulties, and solve the effects of complicated construction procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

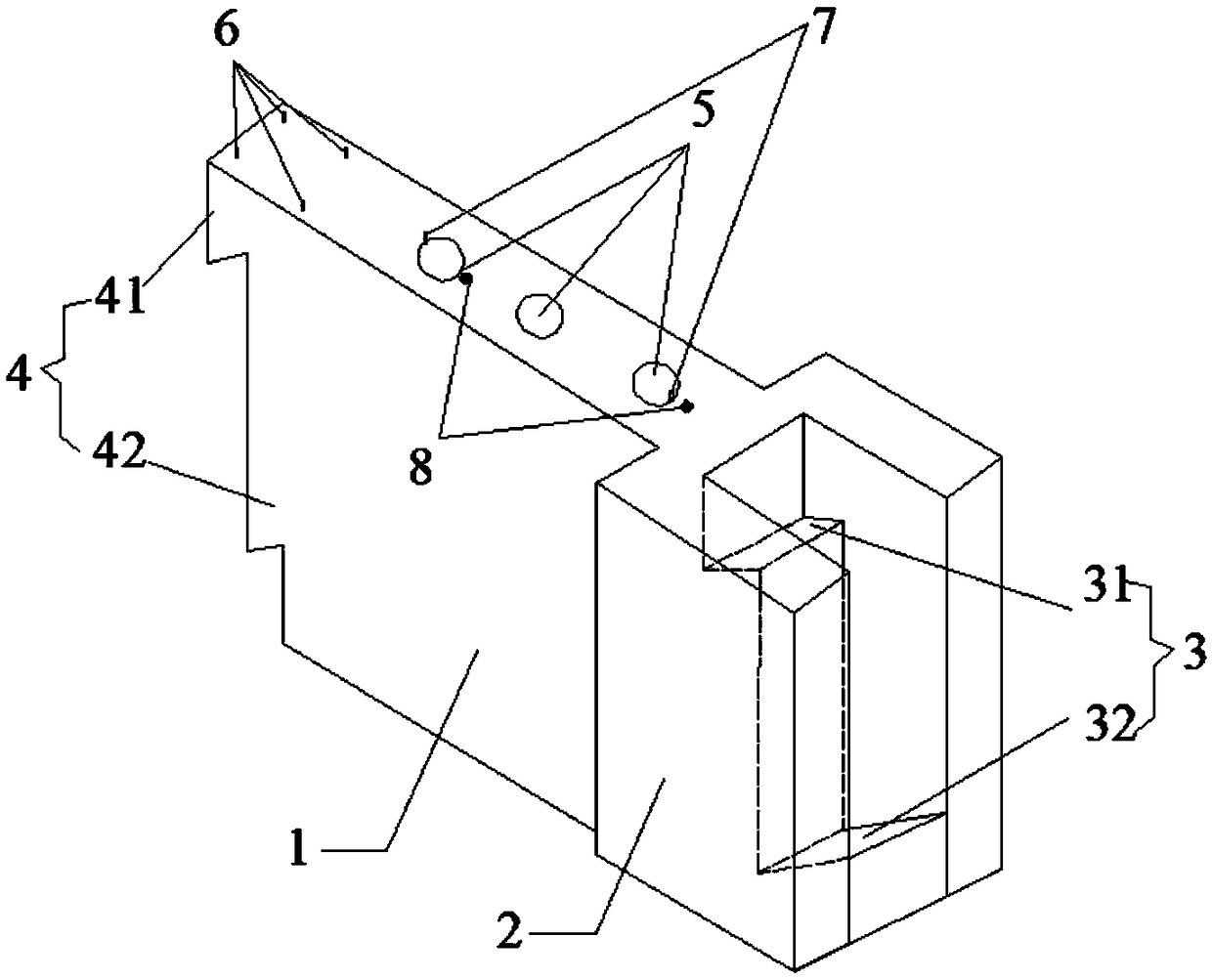

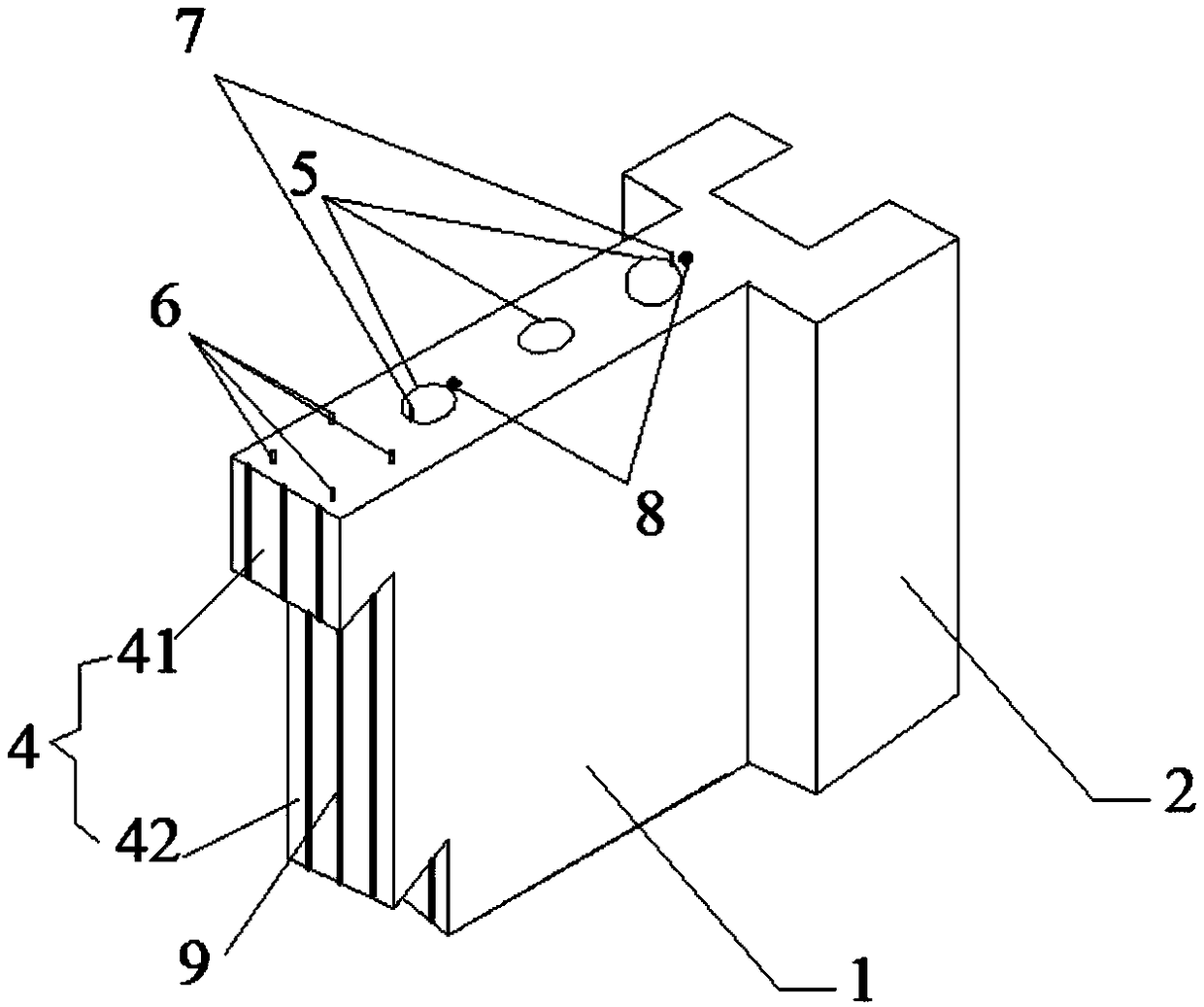

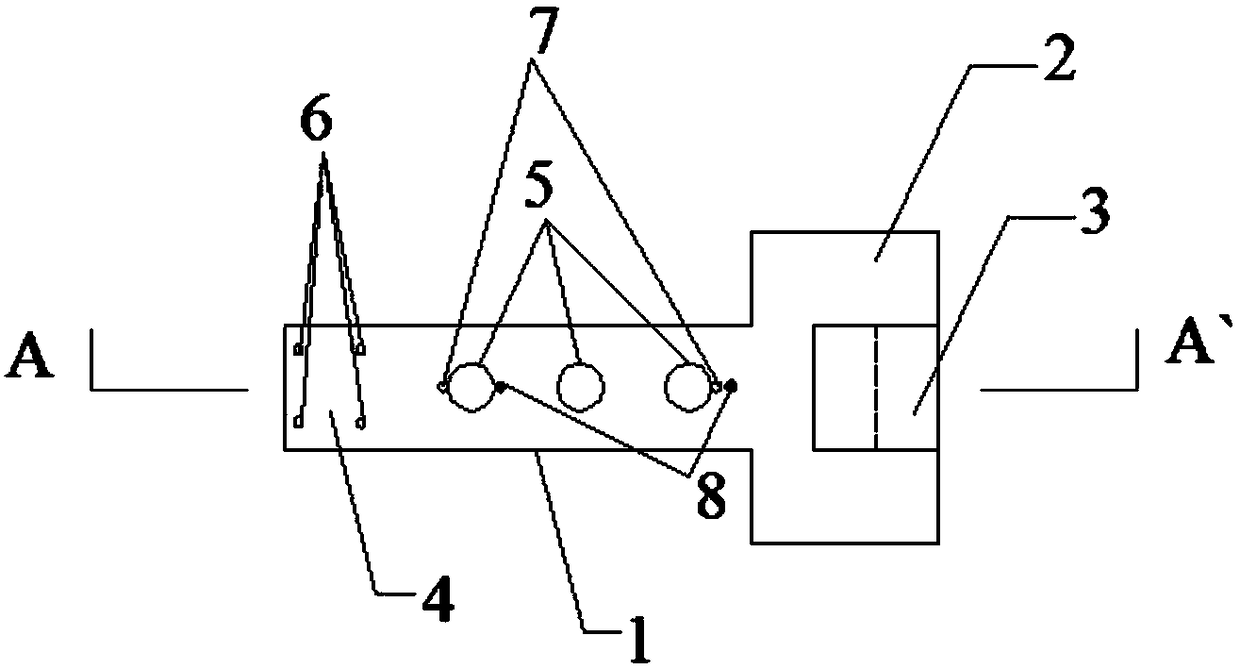

[0025] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

[0026] The prefabricated underground continuous wall that can be assembled with self-clamping column joints of the present invention includes a plurality of left and right wall panels that are plugged into each other. Such as Figure 1-4 As shown, the wall panel includes a wall body 1 and a column 2 integrally formed. The right side of the column 2 is provided with a card slot 3, and the left side of the wall 1 is provided with a tenon 4 that completely matches the card slot 3.

[0027] Wall 1 and column 2 are equal in height. The section length of the column 2 is not less than 500mm, the width is greater than that of the wall 1, and it is not less than 200mm higher than the side of the wall 1 in the horizontal direction, and the length of the overlap between the wall 1 and the column 2 is not less than 200mm. The card slot 3 is provided in the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com