Well cellar for sewage discharge pipelines

A sewage pipe and sewage discharge technology, which is applied in waterway systems, drainage structures, water conservancy projects, etc., can solve problems such as easy leakage, unfavorable municipal engineering construction, and impact on the surrounding environment, so as to avoid leakage, improve production efficiency, Ease of gathering and cleanup

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

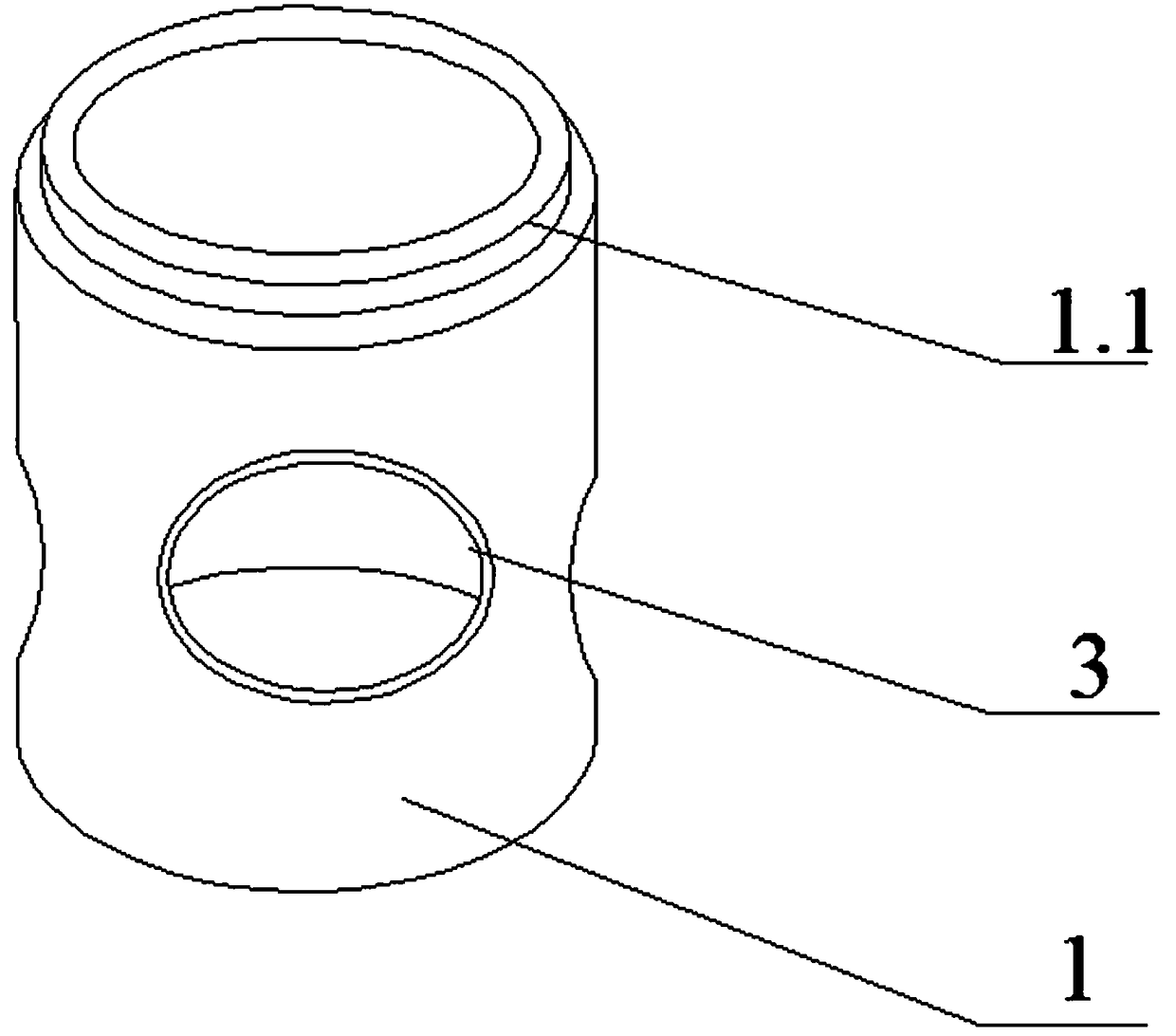

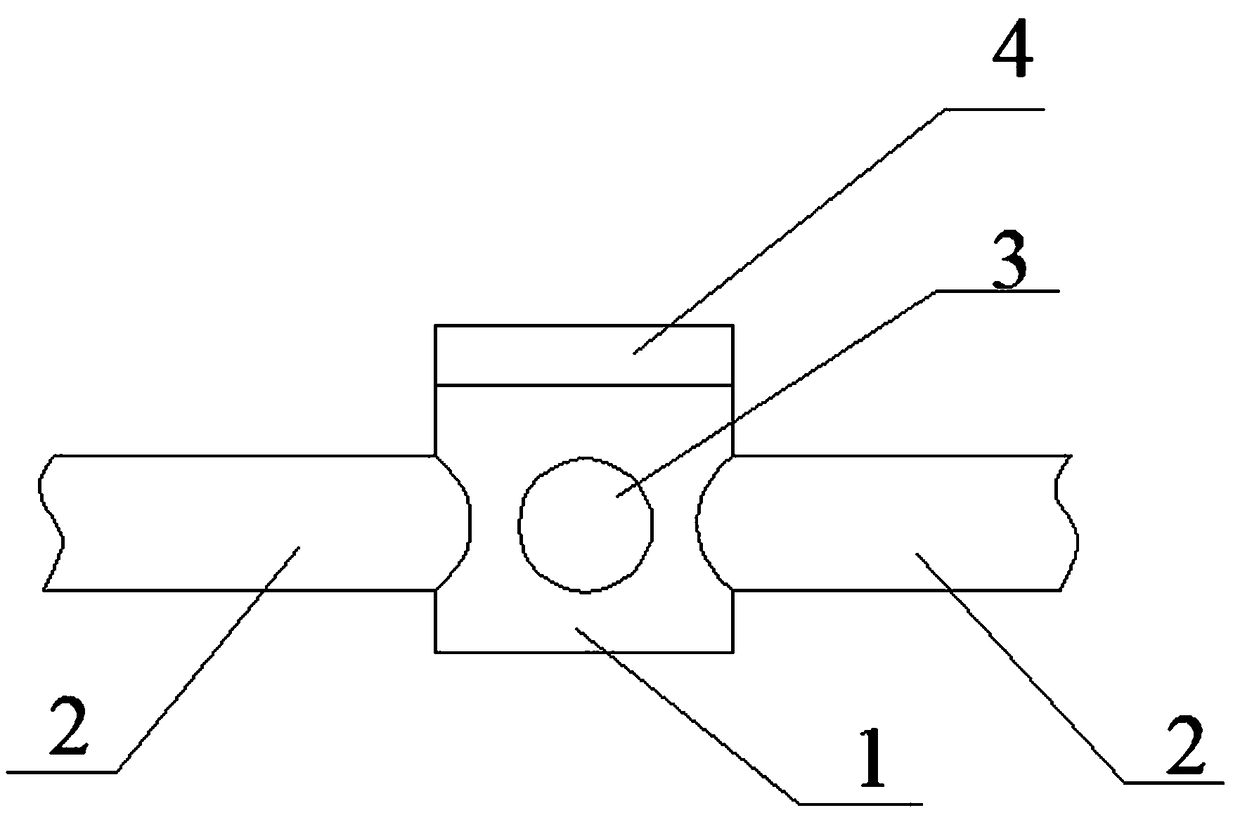

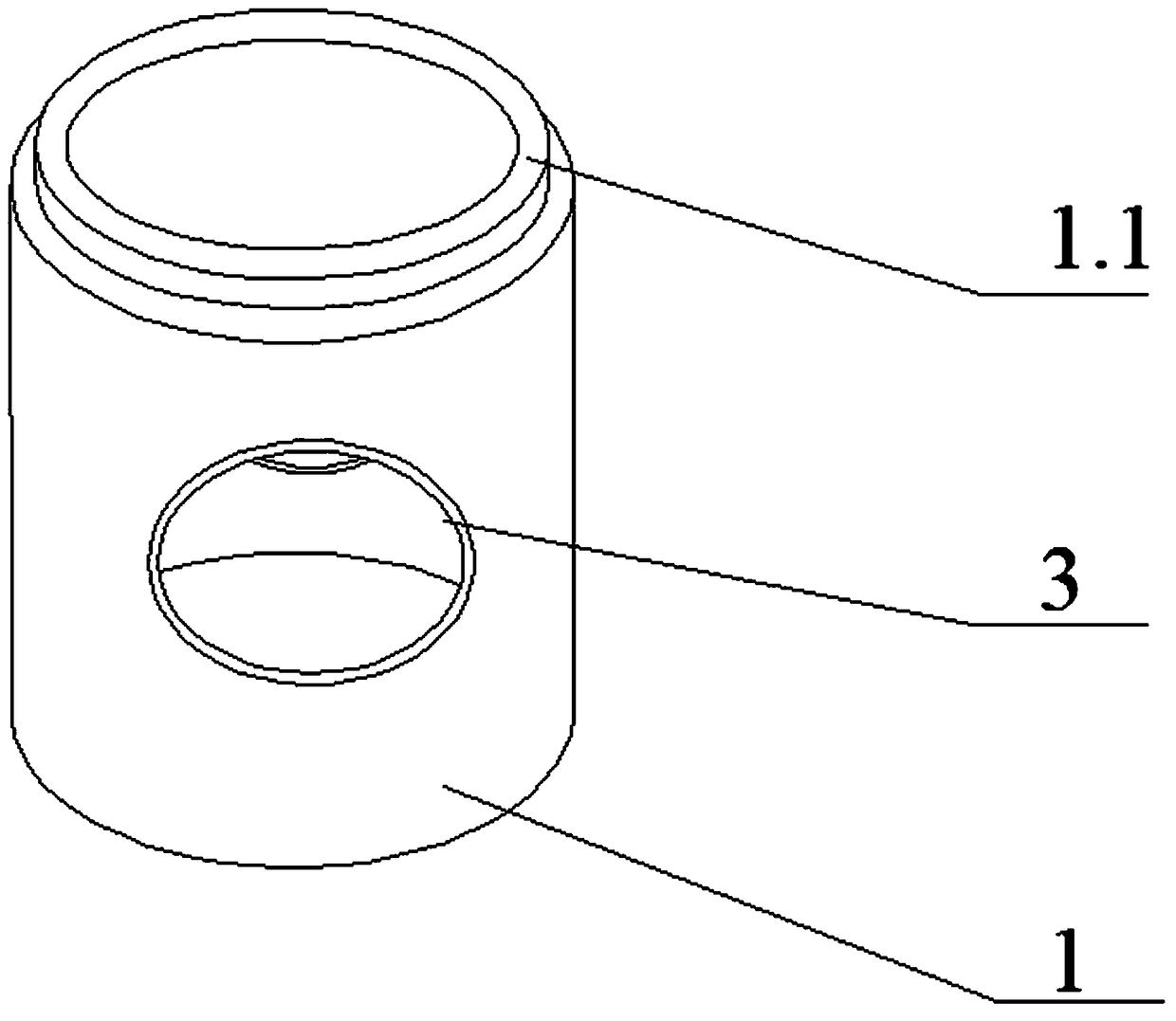

[0020] Such as Figures 1 to 7 As shown, a well pit for sewage pipelines, it includes a well pit body 1 made of reinforced concrete, the well pit body 1 is a hollow cylindrical structure, the bottom of which is closed, and the top is open. The side wall is provided with a water hole 3 for connecting the port of the sewage pipe 2. The height of the bottom of the water hole 3 is higher than that of the bottom of the well cell body 1, and the top of the well cell body 1 is also provided with a top cover 4. In this embodiment, when the well cellar body 1 is manufactured, the steel cage is prefabricated first, and then put into a formwork or a model, and the well cellar body 1 is formed after pouring concrete.

[0021] Preferably, as Figure 6 As shown, the top cover 4 is made of steel frame 4.1 poured concrete, and the steel frame 4.1 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com