Heat pump drying system

A technology of heat pump drying and drying chamber, which is applied in the direction of drying solid materials, drying gas arrangement, local agitation dryer, etc. It can solve the problems that the evaporator cannot meet the process requirements of large flow drying medium and the heat transfer performance of the condenser is difficult to adjust, etc. Achieve the effect of conveniently controlling heat balance and changing heat dissipation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

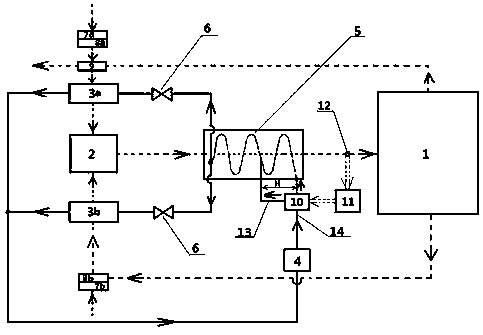

[0023] see figure 1 The heat pump drying system provided in this embodiment includes a drying chamber 1, a fan 2, a first evaporator 3a, a second evaporator 3b, a compressor 4, a condenser 5, a throttle valve 6, a first fresh air valve 7a, a second Two fresh air valves 7b, a first air filter 8a, a second air filter 8b, a heat exchanger 9, a three-way valve 10, a controller 11, and a temperature and humidity sensor 12.

[0024] The first evaporator 3a and the second evaporator 3b are arranged side by side in parallel, and are connected in series with the coiled tube of the condenser 5. Between the first evaporator 3a and the condenser 5 and the second evaporator 3b and the The connecting pipes of the condenser 5 are respectively provided with the throttle valve 6, the fan 2 is installed in the middle of the first evaporator 3a and the second evaporator 3b, and the first evaporator 3a and the second evaporator 3b The air outlet of the second evaporator 3b communicates with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com