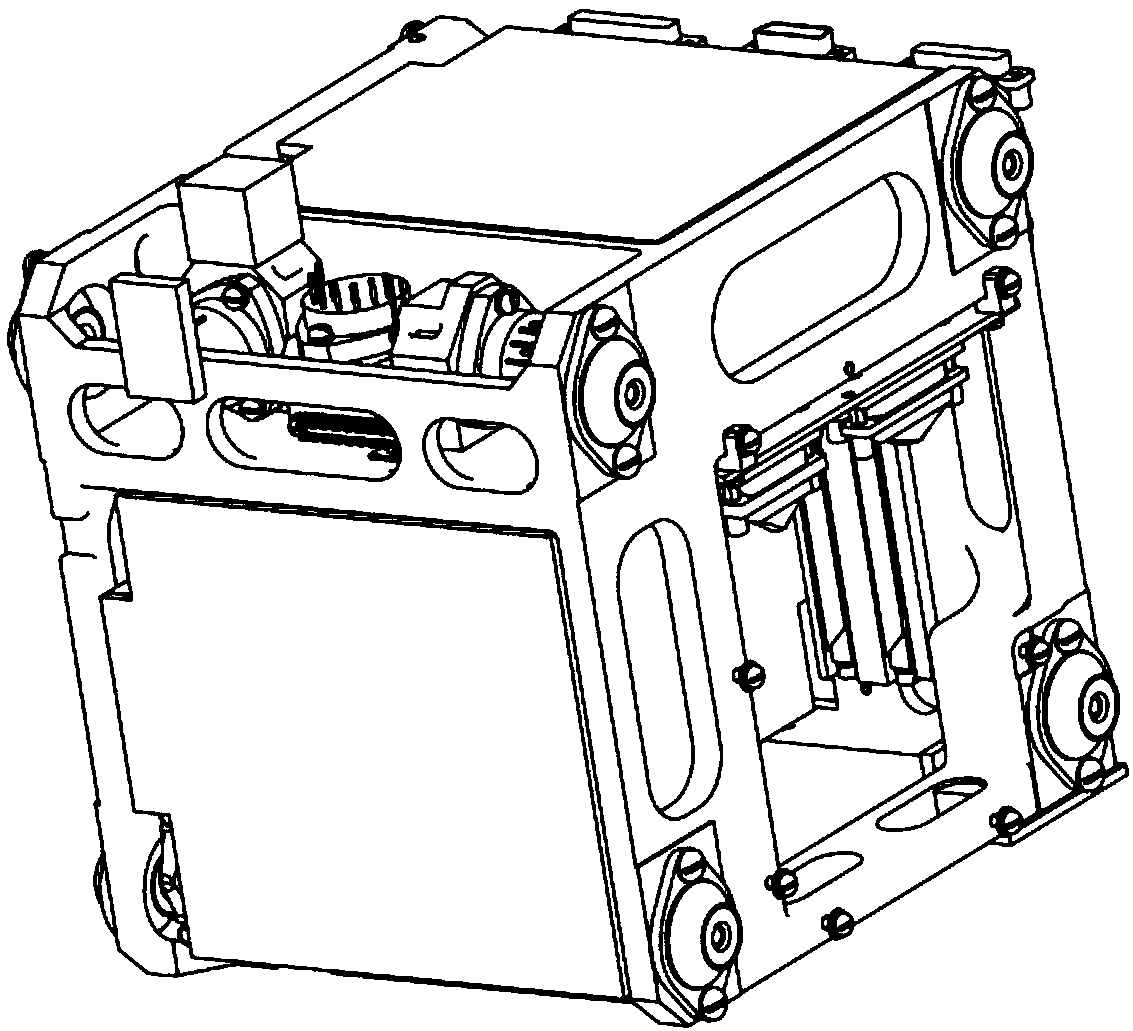

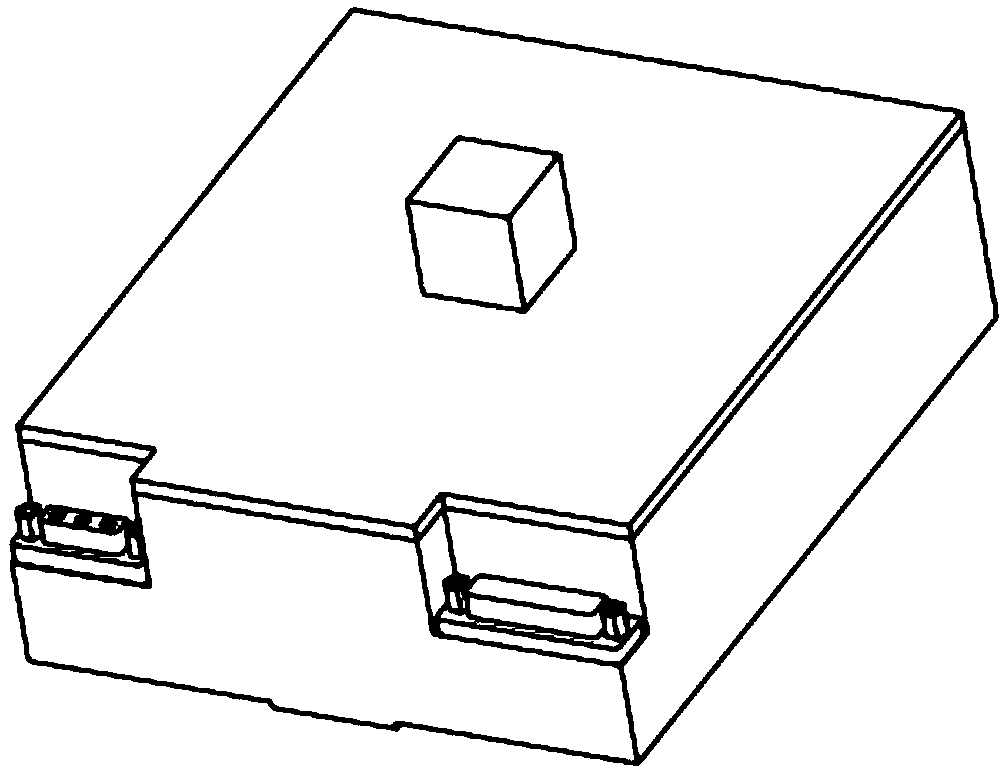

High-accuracy disassembling method of laser inertia group inertia body

A disassembly method and high-precision technology, applied in the field of inertial navigation, can solve the problems of unavoidable disassembly of the body and large difference in instrument output, and achieve the effects of shortening the time of high-precision repeated assembly, high reliability, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

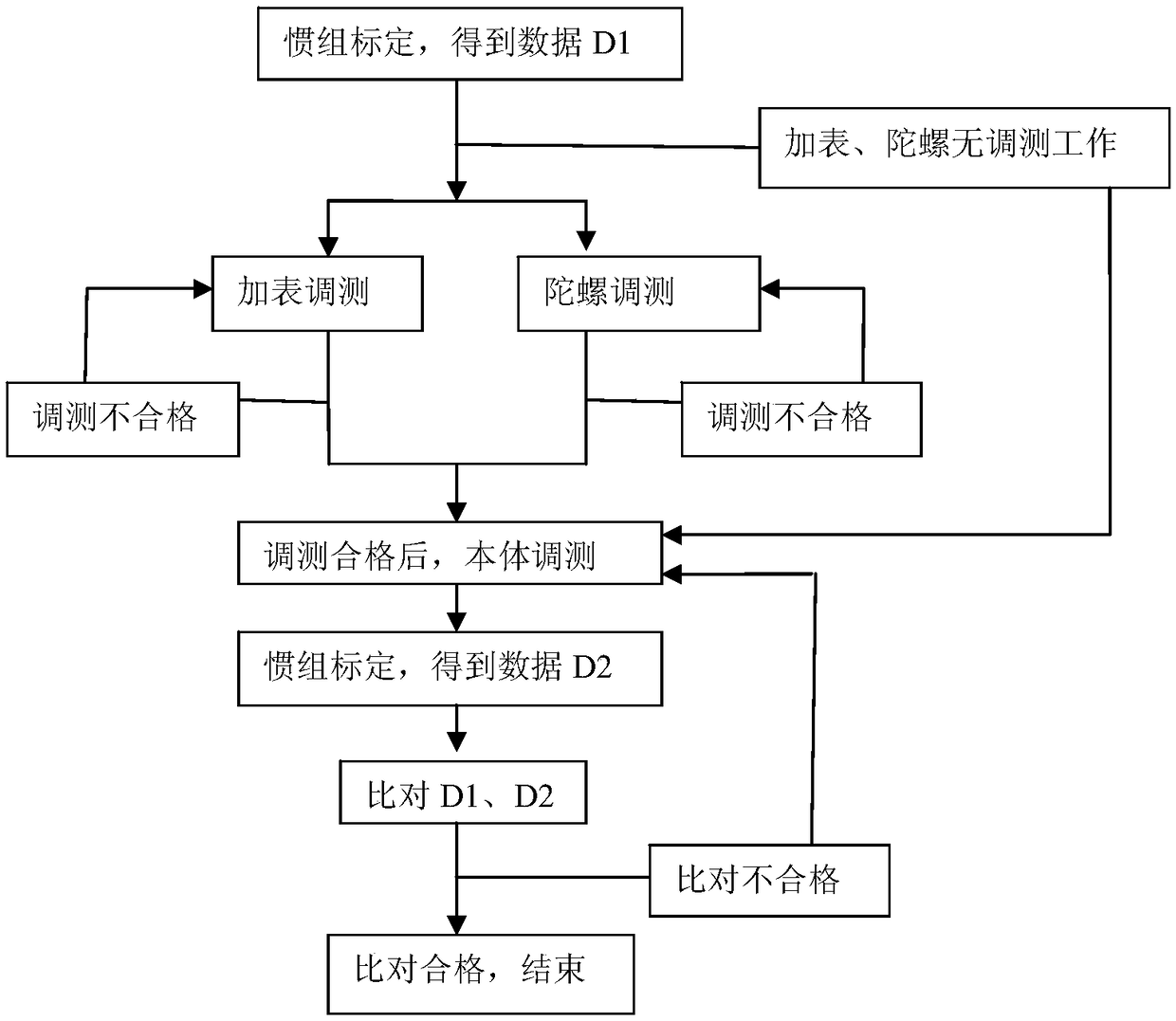

[0055] 1) Body commissioning:

[0056] Before this test, the inertial group first calibrates a set of data D1, and the test is carried out after the inertial group is fully cooled. Then use cotton dipped in alcohol to wipe clean the inertial group installation surface and marble plane, place the inertial group flat on the marble plane, and remove the inertial group cover. Assemble the adjustment tooling to the body, and the three hexagon socket screws for adjustment are in a loose state. After the electronic level is turned on and stabilized, place the electronic level on the upper surface of the tooling, and measure the initial non-levelness A1 (324) in the long axis direction of the body and A2 (156) in the short axis direction.

[0057] Tighten the three screws of the assembly tool just to withstand the box, keep the screws still, loosen the 8 screws of the shock absorber, and use an electronic level to measure the unlevelness A3 (300) in the direction of the long axis of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com