Device for detecting sealing performances of rubber sealing ring in high-pressure hydrogen

A technology of rubber sealing ring and high-pressure hydrogen, which is applied in the direction of liquid tightness measurement by using liquid/vacuum degree, and by measuring the increase and deceleration rate of fluid, etc. It can solve the problems of affecting the sealing performance of the sealing ring, shortening the life of parts, and interference. Achieve the effect of improving measurement accuracy and avoiding corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

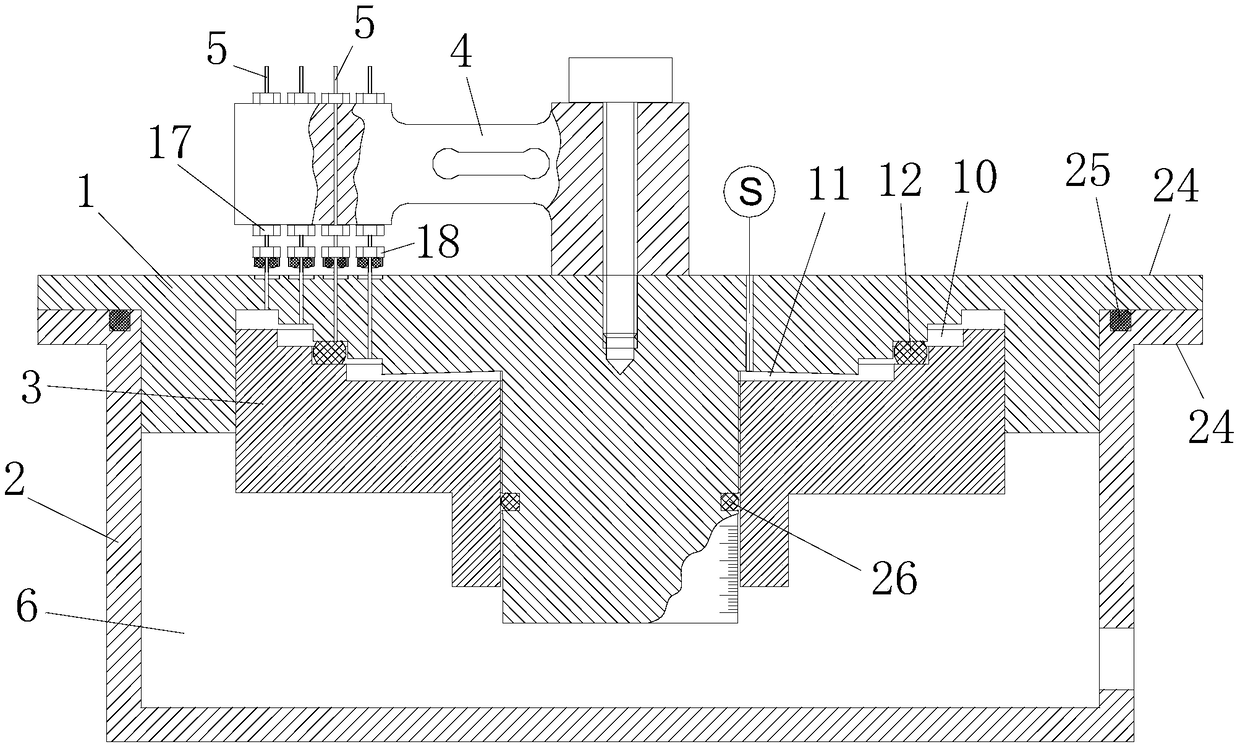

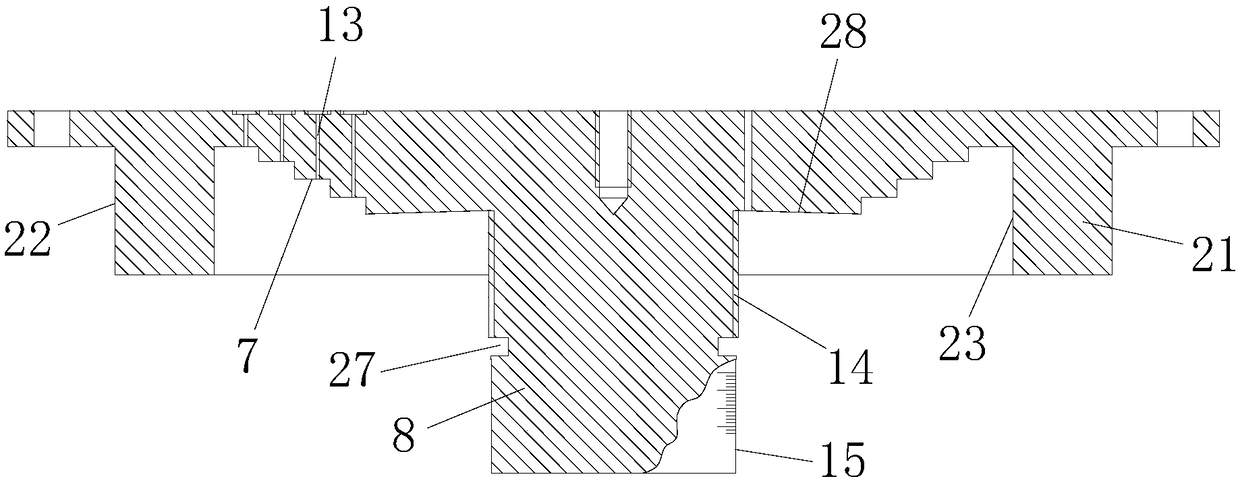

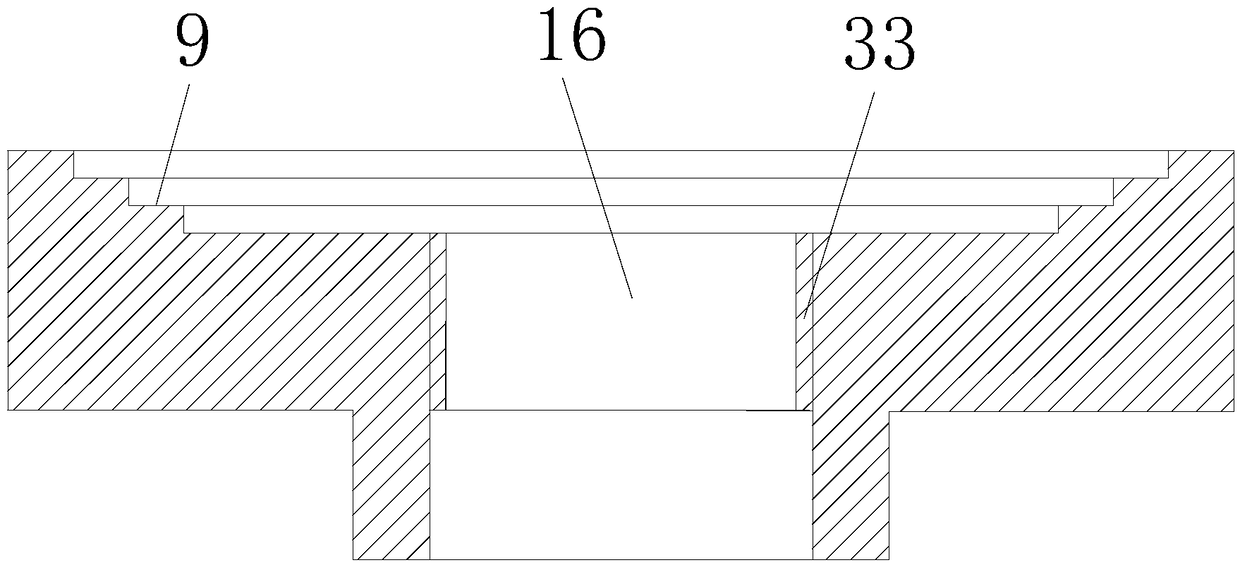

[0030] A device for detecting sealing characteristics of a rubber sealing ring under high-pressure hydrogen gas, comprising: a sealing upper cover 1, a pressure chamber 2, a sealing lower cover 3, a cantilever beam type pressure sensor 4, and a dowel 5, and the sealing upper cover 1 is sealed in the pressure On the chamber 2, an air chamber 6 is formed between the sealing upper cover 1 and the inner wall of the pressure chamber 2; the sealing upper cover 1 is provided with a stepped detection surface 7 and an assembly column 8 corresponding to the air chamber 6, and the sealing lower cover 3 is arranged in the air chamber 6 and sealed onto the assembly column 8, the lower sealing cover 3 is provided with a step fitting surface 9 corresponding to the step detection surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com